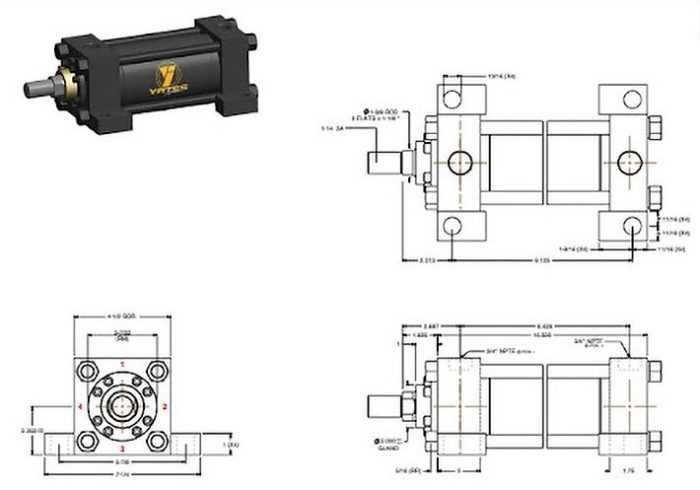

How you can measure hydraulic cylinder precisely is essential for making certain optimum efficiency and longevity of hydraulic programs. Understanding the various kinds of cylinders, the suitable instruments, and the precise measurements wanted is vital to attaining precision. This information will stroll you thru the complete course of, from choosing the precise instruments to decoding the outcomes.

Hydraulic cylinders are important elements in numerous functions, from building gear to industrial equipment. Correct measurement ensures the cylinder meets design specs and features reliably. This detailed information offers step-by-step directions, making correct measurement accessible to anybody working with hydraulic programs.

Introduction to Hydraulic Cylinder Measurement

Hydraulic cylinders are important elements in numerous mechanical programs, remodeling fluid stress into linear movement. They energy every little thing from heavy-duty building gear to specific automated equipment. Understanding and precisely measuring these crucial elements is paramount for making certain optimum efficiency, security, and longevity.Correct measurement of hydraulic cylinders is essential for making certain correct performance and stopping pricey failures. Incorrect dimensions can result in untimely put on, decreased effectivity, and potential security hazards.

Understanding the exact dimensions permits for correct number of elements, making certain the cylinder operates inside its design parameters and minimizes danger of malfunction.

Frequent Causes for Measuring Hydraulic Cylinder Dimensions

Exact measurements are mandatory for numerous functions. Correct sizing ensures the cylinder can deal with the required load and pace. Matching cylinder dimensions to current equipment and programs is important for seamless integration. Measurements additionally facilitate correct upkeep, making certain components are changed with appropriate specs, stopping surprising downtime.

Kinds of Hydraulic Cylinders and Their Functions

Hydraulic cylinders are categorized into numerous varieties, every designed for particular duties. Understanding these varieties is important for choosing the suitable cylinder for a given utility.

| Cylinder Kind | Typical Measurements | Typical Functions |

|---|---|---|

| Single Performing | Stroke Size, Bore Diameter | Lifting gates, easy actuation, functions the place one-way motion is enough. |

| Double Performing | Stroke Size, Bore Diameter, Rod Diameter | Functions requiring bi-directional motion, resembling excavators, presses, and materials dealing with programs. |

| Telescopic | A number of stroke lengths, bore diameters, and rod diameters | Functions requiring prolonged attain and variable stroke lengths, resembling telescopic loaders, cranes, and aerial lifts. |

| Pneumatic/Hydraulic | Stroke size, bore diameter, rod diameter, and port dimensions | Functions requiring fast response and excessive energy output, resembling automated equipment and industrial gear. |

The desk above Artikels widespread hydraulic cylinder varieties and the important thing measurements required for every. The precise measurements wanted will range based mostly on the precise utility, however these are basic for correct sizing and performance.

Significance of Exact Measurement Strategies

Using exact measurement strategies ensures correct knowledge for design and operation. Excessive-precision devices are mandatory for crucial functions, resembling aerospace or medical gear. Inaccurate measurements can lead to efficiency points and security hazards. As an example, a barely off-diameter cylinder rod in a press might result in materials injury and security issues.

Important Measurement Instruments and Strategies

Mastering hydraulic cylinder measurement hinges on precision and the right utility of specialised instruments. Correct dimensions are crucial for correct performance, making certain optimum efficiency and longevity of the cylinder. This part delves into the important instruments and strategies required for exact measurements.Exact measurement is paramount in hydraulic cylinder work. Inaccurate measurements can result in compatibility points, efficiency issues, and probably hazardous conditions.

This part will information you thru the choice and use of varied instruments to attain correct outcomes.

Frequent Measurement Instruments

A wide range of instruments facilitate correct hydraulic cylinder measurements. Selecting the suitable software is determined by the precise dimension being measured and the specified degree of precision.

- Micrometer: A micrometer is a extremely exact instrument able to measuring extraordinarily small distances. Its calibrated screw mechanism permits for exact readings, making it very best for measuring bore diameter, rod diameter, and different crucial dimensions.

- Caliper: Calipers are versatile instruments providing each inside and exterior measurements. They’re well-suited for measuring bore diameter, rod diameter, and stroke size. Vernier calipers present even larger precision in comparison with normal calipers.

- Rule: A easy rule is appropriate for fast estimations and preliminary measurements. Its easy design and low value make it a precious software for preliminary assessments, however its accuracy is decrease than micrometers and calipers.

Precision in Measurement

Attaining exact measurements is essential for hydraulic cylinder functions. Even small discrepancies can have vital penalties, impacting performance and security. Understanding the accuracy limitations of every software is important for choosing the precise software for the duty.

Excessive precision is important for optimum hydraulic cylinder efficiency.

Think about the tolerance ranges specified by the cylinder’s design or utility necessities.

Comparability of Measurement Instruments

The desk under summarizes the accuracy and utility of various measurement instruments.

| Software | Accuracy | Utility |

|---|---|---|

| Micrometer | Excessive | Exact measurements of small dimensions, resembling bore diameter and rod diameter. Appropriate for crucial tolerances. |

| Caliper | Reasonable | Measuring exterior and inside dimensions, together with stroke size and bore diameter. Sensible for basic measurements. |

| Rule | Low | Tough estimations of stroke size. Appropriate for preliminary assessments. |

Measuring Hydraulic Cylinder Dimensions

Correct measurement of key dimensions is crucial. Comply with these steps for measuring stroke size, bore diameter, and rod diameter.

Measuring Stroke Size

- Place the cylinder in its totally retracted place.

- Fastidiously measure the space between the 2 ends of the cylinder utilizing a caliper or a extremely correct rule. Make sure the measurement is taken perpendicular to the cylinder’s axis.

- Repeat the measurement a number of instances to make sure consistency.

Measuring Bore Diameter

- Place the caliper’s jaws across the cylinder’s bore.

- Make sure the jaws are firmly pressed in opposition to the cylinder’s internal floor to keep away from errors on account of slippage.

- Learn the caliper’s measurement.

- For larger precision, use a micrometer.

Measuring Rod Diameter

- Place the caliper’s jaws across the cylinder’s rod.

- Make sure the jaws are firmly pressed in opposition to the rod’s floor to keep away from errors.

- Learn the caliper’s measurement.

- For higher accuracy, use a micrometer.

Measuring Hydraulic Cylinder Specs

Unlocking the secrets and techniques of hydraulic cylinders includes exact measurement of their key specs. Correct measurements are essential for making certain correct operation, load capability, and general system efficiency. Understanding these dimensions empowers engineers to design, fabricate, and preserve hydraulic programs effectively.

Hydraulic Cylinder Specs

Hydraulic cylinders are outlined by a number of crucial specs. Understanding these parameters is prime to making sure the cylinder’s suitability for a specific utility. These specs should not merely summary numbers; they characterize the cylinder’s practical capabilities.

| Specification | Significance | Measurement Methodology |

|---|---|---|

| Stroke Size | Working vary | Measure from one finish to the opposite utilizing a ruler, measuring tape, or a caliper. For advanced geometries, use a laser or digital measuring instrument. |

| Bore Diameter | Capability | Measure the cylinder’s inside diameter utilizing a caliper or a bore gauge. Make sure the measurement is taken at a number of factors to account for potential variations. |

| Rod Diameter | Load capability | Measure the diameter of the piston rod utilizing a caliper. A micrometer offers excessive precision for crucial functions. |

Stroke Size Measurement Strategies

Figuring out stroke size includes measuring the space between the intense positions of the cylinder’s piston. Direct measurement utilizing a measuring tape or ruler is appropriate for easy cylinders. Nonetheless, for cylinders with intricate configurations or these requiring excessive precision, a laser or digital measuring gadget is really useful. A laser distance meter, for instance, is great for correct stroke size willpower.

Bore Diameter Measurement Strategies

Precisely measuring the bore diameter is important for calculating the cylinder’s capability. A caliper, a specialised software particularly designed for measuring inside diameters, is a standard and efficient technique. A bore gauge will also be employed for exact measurements, notably for crucial functions. At all times take a number of measurements at totally different factors alongside the bore to account for any irregularities.

Rod Diameter Measurement Strategies

The rod diameter straight impacts the cylinder’s load-bearing capability. Calipers are usually used for this measurement. For enhanced precision, micrometers are preferable, notably in functions demanding exact management over the cylinder’s load capability. Micrometers provide a better diploma of accuracy than calipers. A number of measurements ought to be taken to make sure a dependable common.

Comparability of Measurement Strategies

Totally different strategies provide various ranges of precision and ease of use. For primary functions, rulers and measuring tapes present enough accuracy. Nonetheless, for functions requiring larger precision, calipers and micrometers are the popular instruments. Laser measuring devices provide the best accuracy and are perfect for advanced shapes or massive distances. The selection of measurement technique relies upon closely on the precise utility and desired accuracy degree.

Analyzing and Deciphering Measurement Information

Mastering the artwork of analyzing hydraulic cylinder measurements is essential for making certain optimum efficiency and longevity. Correct knowledge interpretation guides knowledgeable selections about cylinder suitability for particular functions. This part dives deep into recording procedures, widespread pitfalls, and insightful interpretations that will help you benefit from your measurements.

Information Recording and Documentation

Exact recording of measurements is paramount for correct evaluation and future reference. A well-maintained document acts as a precious asset, facilitating comparability throughout totally different exams and functions. A structured method ensures that each one crucial knowledge factors are captured constantly.

| Measurement | Worth | Models | Date |

|---|---|---|---|

| Stroke Size | 100 | mm | 2024-10-27 |

| Bore Diameter | 50 | mm | 2024-10-27 |

| Rod Diameter | 25 | mm | 2024-10-27 |

| Journey Pace | 10 | mm/s | 2024-10-27 |

| Working Stress | 100 | bar | 2024-10-27 |

A constant format, as demonstrated within the desk, is important. This permits for straightforward sorting, filtering, and comparability of information. Embrace all related parameters, together with date and time of measurement, environmental circumstances (temperature, humidity), and any particular take a look at circumstances.

Frequent Measurement Errors and Mitigation

A number of components can introduce errors into hydraulic cylinder measurements. Understanding these potential errors is essential for minimizing their impression.

- Incorrect Calibration of Measuring Devices: Guarantee measuring instruments, like calipers and stress gauges, are calibrated recurrently in opposition to recognized requirements. This ensures correct readings, avoiding systematic errors.

- Improper Dealing with of the Cylinder: Make sure the cylinder is supported correctly throughout measurements to keep away from deformation or misalignment, which may result in inaccurate readings. Keep away from exterior forces performing on the cylinder in the course of the course of.

- Parallax Error: At all times preserve a perpendicular view of the measuring instrument to the measurement floor to stop parallax error. This error happens when the observer’s eye will not be straight aligned with the size.

- Environmental Elements: Think about the impact of temperature and humidity on the cylinder’s dimensions. Temperature variations can alter the scale of the cylinder, affecting the accuracy of measurements. Humidity ranges can even have an effect on readings, particularly when coping with supplies that soak up moisture.

Deciphering Measurement Information for Cylinder Suitability, How you can measure hydraulic cylinder

The collected knowledge wants cautious interpretation to evaluate cylinder suitability for a given utility. This course of includes evaluating the measured parameters in opposition to the necessities Artikeld within the utility specs.

- Evaluating Measured Stroke Size to Required Stroke: Make sure the measured stroke size meets the required stroke for the applying. A big discrepancy signifies potential incompatibility.

- Evaluating Bore and Rod Diameters: Confirm that the bore and rod diameters are enough to deal with the required power and pace. Inadequate diameters might result in inadequate power output or untimely put on.

- Assessing Working Stress: The working stress ought to fall throughout the secure working vary of the cylinder. Exceeding the utmost stress can injury the cylinder.

Examples of Information Interpretation

Think about an utility requiring a cylinder to raise a 1000 kg load. Measurements reveal a cylinder with a 50 mm bore, 25 mm rod, 100 mm stroke, and a most working stress of 150 bar. Analyzing this knowledge in opposition to the load necessities, and contemplating the effectivity of the mechanism, helps decide if the cylinder is appropriate for the applying.

- Utility Instance 1: If the calculated power is throughout the required vary, and the pace is enough, the cylinder is appropriate for the applying. If the power is just too low, a bigger bore diameter cylinder is required.

- Utility Instance 2: If the utmost working stress is decrease than the anticipated working stress, the cylinder is unsuitable and a extra strong cylinder with larger stress ranking is required.

Troubleshooting and Upkeep Concerns: How To Measure Hydraulic Cylinder

Mastering hydraulic cylinder measurement is not nearly precision; it is about making certain peak system efficiency and longevity. Troubleshooting potential points and implementing proactive upkeep are essential for avoiding pricey downtime and maximizing the lifespan of your hydraulic cylinders. Understanding widespread pitfalls in measurement and their impression on general system performance is vital to sustaining effectivity.Figuring out and resolving discrepancies in measurement knowledge is paramount to stopping system malfunctions and dear repairs.

This part will discover widespread points, their impression, and efficient decision strategies. Moreover, it would element preventative upkeep duties essential for sustaining correct measurement capabilities over time.

Frequent Measurement Points and Their Impression

Inaccurate hydraulic cylinder measurements can stem from numerous sources, together with defective measuring instruments, improper method, or environmental components. These points can manifest as inconsistencies within the measured dimensions, resulting in miscalculations and, in the end, system efficiency degradation. As an example, a constantly underestimated stroke size might result in untimely put on on the piston rod or insufficient power technology, whereas a mismeasured bore diameter might end in extreme stress fluctuations and attainable cylinder failure.

Calibration errors in measuring instruments or operator errors throughout measurement procedures can even contribute to those points.

Resolving Measurement Discrepancies

Addressing measurement discrepancies requires a scientific method. First, meticulously evaluate the measurement course of to determine potential procedural errors. Test for correct software calibration and make sure the cylinder is in a secure, supported place throughout measurement. If inconsistencies persist, re-measure the cylinder utilizing a unique, calibrated measuring software. If the discrepancy nonetheless persists, think about the opportunity of exterior components affecting the measurements, resembling temperature variations or environmental vibrations.

For instance, if a temperature distinction is the trigger, make sure the cylinder and measurement instruments are on the identical temperature for dependable readings. If mandatory, repeat the measurements in a managed surroundings.

Preventative Upkeep for Hydraulic Cylinder Measurement

Sustaining correct hydraulic cylinder measurements hinges on proactive upkeep. An everyday schedule of calibration checks for measuring instruments is essential. Confirm that your measuring instruments, resembling calipers and micrometers, are calibrated periodically in accordance with producer specs. This ensures the instruments are functioning precisely. Moreover, routine inspections of the hydraulic cylinder itself ought to embody checking for any indicators of damage or injury, resembling dents, cracks, or corrosion.

Common lubrication of the cylinder elements additionally contributes to the accuracy of measurements.

- Calibration Schedule: Set up a daily schedule for calibrating all measuring devices used for hydraulic cylinder measurements. This ensures the accuracy of your measurements over time. Seek the advice of producer tips for particular calibration intervals.

- Visible Inspection: Recurrently examine the hydraulic cylinder for any indicators of injury or put on, resembling dents, cracks, or corrosion. Doc any findings for future reference.

- Lubrication Practices: Adhere to the producer’s really useful lubrication schedule. Correct lubrication reduces friction and put on, impacting the accuracy of measurements.

- Environmental Management: Preserve a managed surroundings for measurement. Keep away from conducting measurements in areas with excessive temperature fluctuations or vital vibrations.

- Documentation: Preserve detailed information of all measurements, calibration checks, and upkeep actions. This permits for straightforward monitoring of cylinder efficiency over time.

Wrap-Up

In abstract, exact measurement of hydraulic cylinders is important for dependable operation. By understanding the different sorts, using the right instruments, and meticulously recording knowledge, you’ll be able to guarantee correct measurements. This information offers a complete method to mastering the method, from preliminary setup to troubleshooting potential points. Bear in mind, correct measurement straight impacts system efficiency and longevity.

Prime FAQs

What are the most typical errors when measuring hydraulic cylinder stroke size?

Frequent errors embody not accounting for the cylinder’s finish caps, utilizing a non-calibrated measuring software, or not holding the rule perpendicular to the cylinder.

How do I select the precise measuring software for a particular hydraulic cylinder?

The most effective software is determined by the scale and sort of cylinder. Micrometers are perfect for exact measurements of small dimensions, calipers for exterior and inside dimensions, and guidelines for tough estimations. Think about the accuracy wanted for the applying.

What are the implications of inaccurate hydraulic cylinder measurements?

Inaccurate measurements can result in untimely put on and tear on the cylinder, system malfunctions, and potential security hazards. It is essential to take care of precision in all measurements.

What if I encounter discrepancies in my measurements?

Test for any apparent points like misaligned elements, free components, or broken instruments. If the discrepancies persist, evaluate your measurements and procedures fastidiously, or seek the advice of a certified technician.