Easy methods to learn oil gauge on oil tank is an important talent for anybody dealing with gasoline storage. Think about the satisfying sight of a full tank, or the pressing must refill when the needle dips dangerously low. This information supplies a complete overview of assorted oil tank gauges, from the basic mechanical needle to the fashionable digital show.

Understanding these gauges empowers you to precisely assess your gasoline ranges, making certain easy operations and avoiding expensive emergencies.

Navigating the complexities of oil tank gauges could be easy, when you grasp the basics. Several types of gauges make the most of various visible cues to symbolize the quantity of oil throughout the tank. From the delicate motion of a needle to the exact numbers on a digital show, this information will decipher these indicators, serving to you rapidly and precisely gauge your oil ranges.

Understanding Oil Tank Gauges

Oil tank gauges are essential for monitoring gasoline ranges and making certain easy operations in varied purposes, from dwelling heating techniques to large-scale industrial services. Figuring out how these gauges work, the different sorts out there, and their respective benefits and downsides is important for making knowledgeable choices about upkeep and buying. This information permits you to select the very best gauge in your particular wants, maximizing effectivity and minimizing downtime.Oil tank gauges present a visible illustration of the fluid degree inside a tank.

They arrive in varied types, every with its personal set of strengths and weaknesses. Understanding these variations will assist you to make knowledgeable choices about the correct gauge in your explicit wants.

Sorts of Oil Tank Gauges

Several types of gauges use varied strategies to measure and show the oil degree. Choosing the proper gauge is dependent upon elements comparable to finances, desired accuracy, and the scale and sort of oil tank.

Mechanical Gauges

Mechanical gauges, typically that includes a needle that strikes throughout a scale, are a standard technique for measuring oil ranges. These gauges usually use a float system that rises and falls with the oil degree, immediately translating the motion into a visible indication on the gauge face. They’re usually dependable and strong, however their accuracy could be affected by elements comparable to the kind of oil or the design of the tank.

Digital Gauges

Digital gauges supply a extra exact and readily-accessible approach to monitor oil ranges. They use sensors and microcontrollers to measure the extent, offering a digital show of the amount. These gauges are extremely correct and sometimes present further knowledge factors, comparable to the precise quantity of oil within the tank. Digital gauges are usually dearer than their mechanical counterparts.

Dipstick Gauges

Dipsticks are a easy and cheap technique to estimate oil ranges. A dipstick is a protracted rod with a marked space that’s inserted into the oil tank. The extent of oil on the dipstick is then in comparison with the markings on the dipstick itself to find out the approximate quantity of oil current. Dipsticks are available and comparatively cheap however are much less exact than mechanical or digital gauges, and require extra guide effort.

Comparability of Gauge Varieties

| Gauge Sort | Execs | Cons | Typical Use Circumstances |

|---|---|---|---|

| Mechanical | Comparatively cheap, easy to grasp, strong and sturdy, typically dependable. | Much less correct than digital gauges, could require calibration, doubtlessly much less exact readings, could be tough to learn in low-light situations. | Small to medium-sized oil tanks the place exact measurements will not be important, purposes with restricted budgets. |

| Digital | Extremely correct, straightforward to learn, typically present further knowledge like quantity, could be remotely monitored. | Dearer than mechanical gauges, could require specialised set up, potential for malfunction if the sensor is broken. | Functions needing exact measurement, massive tanks, monitoring techniques requiring knowledge integration. |

| Dipstick | Least costly choice, available, easy to make use of, no exterior energy wanted. | Least correct, requires guide effort, potential for errors in studying, not appropriate for steady monitoring. | Small tanks, occasional checks, fast estimates of oil degree. |

Decoding the Gauge Readings

Understanding the markings in your oil tank gauge is essential for making certain your operation runs easily and effectively. Ignoring these readings can result in expensive errors, like operating out of oil unexpectedly or overfilling the tank, doubtlessly damaging your gear. Let’s dive into deciphering these gauge markings.Oil tank gauges, whether or not digital or analog, use a visible illustration of the oil degree.

This usually includes strains or markings on a scale. Correct interpretation of those markings permits you to exactly assess your oil provide, enabling proactive administration and upkeep.

Understanding Gauge Markings

The markings in your oil tank gauge symbolize totally different ranges of oil within the tank. These markings are usually clearly marked with corresponding values, comparable to percentages or precise quantity measurements (gallons or liters). A typical gauge may have a collection of markings that visually symbolize the fullness of the tank. Every marking signifies a particular degree.

Models of Measurement

Oil tank gauges use standardized items of measurement. Frequent items embody gallons (US or imperial) and liters. The precise unit used will rely on the area and the kind of oil tank. All the time make sure you perceive the items used in your explicit gauge.

Figuring out Oil Quantity

To precisely decide the quantity of oil within the tank, fastidiously study the gauge studying. Line up the present oil degree with the corresponding markings on the gauge. This visible alignment helps in figuring out the precise degree and the amount of oil within the tank. For instance, if the gauge needle factors to the “75%” mark, there’s roughly three-quarters of the tank stuffed with oil.

Exactly decoding the gauge markings, due to this fact, supplies a exact estimate of the out there oil.

Oil Degree Desk

| Oil Degree | Description | Motion Required |

|---|---|---|

| Low | The gauge needle is close to the bottom marking, indicating a minimal quantity of oil remaining. | Instantly order a refill of oil to stop gear malfunction. Contact the provider or vendor for immediate supply. |

| Medium | The gauge needle is positioned between the high and low marks, indicating a average oil provide. | Schedule a routine oil examine and monitor the extent frequently to make sure adequate provide. |

| Excessive | The gauge needle is close to the best marking, signifying a considerable quantity of oil within the tank. | Make sure the oil degree shouldn’t be exceeding the utmost capability to stop spillage or injury. Observe the studying for future reference. |

Frequent Issues and Troubleshooting

Studying your oil tank gauge precisely is essential for stopping expensive points. A defective gauge can result in operating out of oil unexpectedly, inflicting engine injury or downtime. Understanding potential issues and how you can troubleshoot them is vital to sustaining your gear and avoiding expensive repairs.Correct gauge readings are important for optimum efficiency and longevity of your oil tank system.

Incorrect readings can result in overfilling, which could be simply as detrimental as operating out of oil. Figuring out the widespread issues and how you can deal with them empowers you to proactively preserve your gear and keep away from sudden points.

Potential Issues Affecting Oil Tank Gauge Readings

A number of elements can affect the accuracy of your oil tank gauge. These vary from easy sensor malfunctions to extra complicated mechanical points throughout the tank itself. Figuring out these potential issues permits you to establish and deal with them promptly.

- Defective Sensors:

- The sensor, the center of the gauge system, could be broken or malfunctioning, resulting in inaccurate readings. This could occur resulting from put on and tear, bodily affect, or electrical points. A broken sensor may present a continuing low degree, a continuing excessive degree, or fluctuating readings, whatever the precise oil degree.

- Mechanical Points within the Tank:

- Inside tank elements, just like the dipstick or the mechanism connecting the sensor to the tank, could be the supply of inaccurate readings. A bent dipstick, for instance, will not precisely replicate the oil degree. Free connections or obstructions throughout the tank can even result in defective readings. Corrosion can even trigger issues with the tank’s inside or the mechanism connecting the sensor to the tank.

- Environmental Elements:

- Temperature fluctuations can have an effect on the accuracy of some gauges. Excessive temperatures can alter the oil’s density, which may result in inaccurate readings. Moreover, mud, particles, or contaminants throughout the tank can affect sensor efficiency and thus result in inaccurate gauge readings.

- Electrical Issues:

- Electrical points within the wiring or the gauge itself can result in fluctuating or incorrect readings. A brief circuit, for instance, may trigger erratic habits. Free connections or broken wires can even have an effect on the gauge’s accuracy.

Troubleshooting Inaccurate Gauge Readings

Troubleshooting a malfunctioning oil tank gauge is a scientific course of. A step-by-step method can assist you pinpoint the issue rapidly and effectively.

- Visible Inspection: Fastidiously study the gauge, the sensor, and the wiring for any seen injury, corrosion, or unfastened connections. Search for bodily indicators of injury to the dipstick, or for any apparent obstructions throughout the tank.

- Verify the Sensor Connection: Make sure the sensor is securely related to the tank and the gauge. Confirm that every one connections are tight and free from corrosion.

- Take a look at the Wiring and Connections: Examine the wiring for any indicators of injury, fraying, or unfastened connections. Use a multimeter to examine the continuity of the wiring.

- Think about Environmental Elements: If the readings are erratic, attempt to decide if environmental situations (like temperature fluctuations) are enjoying a job. If that’s the case, attempt to management these elements to see if the readings enhance.

- Seek the advice of the Producer’s Handbook: Seek advice from the producer’s directions for particular troubleshooting steps in your oil tank gauge mannequin. This could typically present beneficial insights and detailed procedures.

- Skilled Help: In the event you can’t pinpoint the issue, seek the advice of a professional technician. Knowledgeable can diagnose and restore complicated points extra successfully.

Security Precautions: How To Learn Oil Gauge On Oil Tank

Oil tanks, whereas important for a lot of operations, pose potential hazards if not dealt with correctly. Understanding the dangers related to oil and implementing the correct security measures is essential for stopping accidents and sustaining a protected work atmosphere. Ignoring these precautions can result in severe accidents or environmental injury. Correctly skilled personnel and a methodical method to grease tank administration are paramount.Working round oil tanks requires cautious consideration of potential risks.

The precise hazards rely on the kind of oil, the scale of the tank, and the encompassing atmosphere. A complete understanding of the dangers is step one towards stopping accidents. By adhering to security procedures, you may considerably cut back the chance of unlucky incidents.

Hazards Related to Oil and Oil Tanks

Oil itself presents quite a lot of risks. It could actually trigger pores and skin irritation, burns, and respiratory issues. Spills can create hazardous conditions, resulting in environmental air pollution and slips and falls. Oil-based merchandise, like fuels and lubricants, may also be flammable and doubtlessly explosive, necessitating cautious dealing with. The heavier the oil, the extra vital the potential for environmental injury in case of a spill.

The potential for ignition from static electrical energy additionally exists, significantly in large-scale operations. Understanding these hazards is important for protected operation.

Significance of Correct Air flow

Correct air flow is important when working close to oil tanks to mitigate the dangers of inhaling dangerous fumes and vapors. These vapors could be extraordinarily harmful, inflicting dizziness, nausea, complications, and even unconsciousness. Inadequate air flow can result in a buildup of flammable gases, rising the danger of fires and explosions. Correct air flow techniques are a important part of a protected oil tank atmosphere.

Common inspection and upkeep of air flow techniques are essential to make sure their effectiveness. This typically contains monitoring carbon monoxide ranges, as this can be a widespread by-product of combustion or incomplete combustion, which could be deadly.

Security Tools for Checking Oil Ranges

Applicable security gear is significant when checking oil ranges. This contains protecting clothes, comparable to gloves, security glasses, and a respirator. These things shield towards direct contact with oil, splashes, and potential fumes. Gloves ought to be immune to the particular kind of oil being dealt with. Security glasses or goggles ought to be impact-resistant to safeguard the eyes.

A respirator is essential when coping with oil vapors, particularly in confined areas. A primary-aid equipment ought to be available in case of minor accidents or accidents. Moreover, think about using non-sparking instruments when working round oil tanks, to stop ignition.

Emergency Procedures

Having a well-defined emergency process is important in case of an incident. This could embody protocols for dealing with spills, fires, and different emergencies. The process ought to Artikel the roles and tasks of personnel concerned. Coaching on emergency procedures ought to be performed frequently to make sure everybody is ready and educated. Having a clearly outlined chain of command and emergency contact data available can also be essential.

Guarantee personnel are skilled to acknowledge and reply to potential emergencies.

Particular Gauge Varieties

Figuring out your oil tank’s gauge kind is essential for correct readings. Several types of gauges react otherwise to modifications in oil degree, affecting the way you interpret the displayed data. Understanding these nuances will assist you to keep away from overfilling or operating low on essential fluids.Completely different gauge sorts make use of varied strategies to measure oil ranges, every with its personal strengths and weaknesses.

Elements like accuracy, price, and set up complexity affect the selection of gauge for a selected utility.

Float-Sort Gauges

Float-type gauges are a standard and comparatively cheap technique for measuring oil ranges. A buoyant float, usually manufactured from a light-weight materials like plastic or metallic, strikes up and down with the oil degree. This motion is mechanically linked to a pointer on a calibrated scale, permitting you to visually decide the quantity of oil within the tank.These gauges are usually correct inside a spread of ±1-2% of the complete tank capability, although this may differ relying on the particular gauge mannequin and set up situations.

Their reliability is usually good, however could be affected by elements just like the float’s lubrication or corrosion, in addition to the potential for the float to get caught or obstructed. Common upkeep and calibration are important for sustaining accuracy.

Dip-Stick Gauges

Dip-stick gauges are a easy and direct technique for measuring oil ranges, typically present in smaller tanks or gear. An extended, skinny rod, the dipstick, is inserted into the tank, and the oil degree is decided by observing the oil residue on the dipstick. The dipstick is then cleaned and re-inserted to acquire a brand new studying.Accuracy relies upon considerably on the dipstick’s design and the consumer’s precision.

Careless dealing with or improper wiping can result in inaccurate readings. Dip-stick gauges typically present much less exact measurements in comparison with float-type gauges, with potential error charges starting from ±3-5%. These gauges are perfect for fast checks however will not be appropriate for important purposes requiring excessive accuracy.

Strain Gauges

Strain gauges are sometimes utilized in purposes the place the oil degree is tough to measure immediately. These gauges measure the strain exerted by the oil column throughout the tank, which is then transformed into a visible illustration of the oil degree. Strain gauges are significantly helpful in tanks with uncommon shapes or configurations.The accuracy of strain gauges is very depending on the calibration of the gauge and the pressure-level conversion formulation.

Fluctuations in ambient temperature can even have an effect on the accuracy of those gauges. Strain gauges are usually extra correct than dipstick gauges however much less correct than float-type gauges, usually with an accuracy of ±1-3% relying on the gauge kind and set up.

Comparability Desk

| Gauge Sort | Accuracy | Reliability | Price | Suitability |

|---|---|---|---|---|

| Float-Sort | ±1-2% | Good | Reasonable | Basic-purpose tanks |

| Dip-Stick | ±3-5% | Reasonable | Low | Small tanks, fast checks |

| Strain | ±1-3% | Good | Reasonable to Excessive | Tanks with complicated shapes |

Observe: Accuracy values are approximate and may differ based mostly on particular gauge fashions and set up situations.

Visible Aids and Illustrations

Understanding oil tank gauges goes past simply numbers. Visible representations make the method of decoding gauge readings considerably simpler. Clear visuals assist you to rapidly establish the right degree and spot potential issues. These aids additionally assist you to perceive the several types of gauges and the way they work.Visible aids are essential for anybody working with oil tanks, from householders to industrial operators.

This part supplies detailed visuals that will help you rapidly and precisely assess your oil tank ranges and gauge performance.

Oil Tank with Gauge

A typical oil tank incorporates a gauge, often mounted on the tank itself or a close-by panel. The gauge supplies a visible illustration of the oil degree throughout the tank. Think about a cylindrical tank, maybe 5 toes tall and three toes in diameter. A gauge, both mechanical or digital, is affixed to the tank, typically close to the highest. This gauge shows the present oil degree contained in the tank.

Mechanical Gauge

Mechanical gauges, generally present in older techniques, use a needle to point the oil degree. The needle strikes throughout a marked scale. An in depth picture would present a round gauge face with a needle pointing to a particular mark on the dimensions. The size is marked with varied ranges, starting from “Empty” to “Full”. Particular markings are essential for decoding the readings precisely.

Completely different markings may embody “1/4 Full”, “1/2 Full”, “3/4 Full”, and “Full”. The needle’s place on the gauge immediately correlates to the extent of oil within the tank.

Digital Show

Digital shows supply a transparent, numerical illustration of the oil degree. The show reveals a exact studying of the oil degree, typically in percentages or liters/gallons. A digital show instance would present a transparent display screen with a quantity, like “75%” or “200 liters”. Variations within the show format may embody “Low”, “Medium”, or “Excessive” indicators. The digital show supplies an easy approach to decide the precise quantity of oil remaining within the tank.

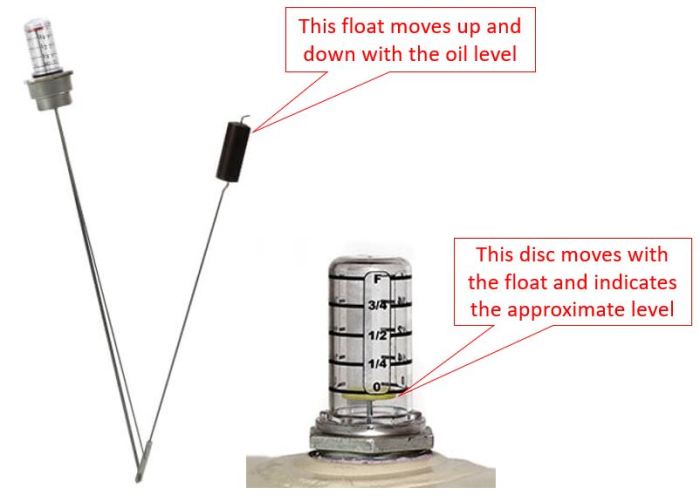

Float-Sort Gauge Diagram

A float-type gauge is a standard mechanism for measuring oil ranges. The diagram illustrates a float, often manufactured from a buoyant materials like plastic or metallic, that rises and falls with the oil degree. The float is related to a mechanism that strikes a pointer or sends a sign to a digital show. The float is immersed within the oil, and its place immediately corresponds to the oil degree.

The diagram would present the float positioned throughout the tank, related to a pointer or a sensor, with clear labels indicating the connection between the float place and the oil degree on the gauge. The float is usually a key part in measuring the oil degree.

Upkeep and Care

Protecting your oil tank gauge in tip-top form is essential for correct readings and avoiding expensive repairs down the road. Common upkeep ensures your gauge capabilities optimally, stopping potential points and lengthening its lifespan. Ignoring maintenance can result in inaccurate measurements, doubtlessly inflicting overfilling or underfilling, impacting gear efficiency and doubtlessly damaging equipment.Correct upkeep includes a mixture of cleansing, calibration, and common checks.

Understanding these procedures will assist you to preserve correct readings and stop expensive issues.

Significance of Common Upkeep

Common upkeep is important for the longevity and accuracy of oil tank gauges. Neglecting these procedures can result in inaccurate readings, gear malfunctions, and even security hazards. A correctly maintained gauge ensures that your oil ranges are exactly measured, stopping overfilling or underfilling, each of which may trigger operational issues.

Mechanical Gauge Cleansing and Upkeep Process, Easy methods to learn oil gauge on oil tank

Mechanical gauges typically require periodic cleansing to keep up accuracy. The next steps Artikel a process for cleansing a mechanical oil tank gauge:

- Disassembly: Fastidiously disassemble the gauge based on the producer’s directions. Incorrect disassembly can result in injury. Seek advice from the guide for particular steps and potential pitfalls.

- Cleansing Parts: Use a gentle brush and a gentle detergent answer to wash all of the gauge elements. Keep away from harsh chemical compounds or abrasive supplies, which may injury the fragile components.

- Drying Parts: Totally dry every part with compressed air or a lint-free fabric. Guarantee all moisture is eliminated to stop corrosion.

- Reassembly: Fastidiously reassemble the gauge within the reverse order of disassembly. Pay shut consideration to the correct alignment of components. Double-check for correct connections and safe fastenings.

Digital Gauge Calibration Process

Digital gauges require periodic calibration to keep up accuracy. This course of ensures the gauge shows the right readings akin to the precise oil degree. Observe these steps for calibrating a digital oil tank gauge:

- Reference Level Setup: Set up a exact reference level throughout the tank. This level ought to be simply accessible and marked constantly for future calibrations.

- Preliminary Studying: Report the gauge’s studying when the tank is totally empty.

- Fill and Report: Fill the tank to a identified, predetermined degree, and thoroughly document the gauge’s studying. Be certain that the fill course of is managed and monitored.

- Calibration: Utilizing the preliminary and ultimate readings, calibrate the gauge by adjusting the suitable parameters within the gauge’s settings menu. Seek advice from the producer’s directions for particular calibration procedures.

Routine Upkeep Schedule

A daily upkeep schedule ensures that oil tank gauges are functioning appropriately. This preventative method is significant for making certain correct readings over time. Observe these tips for routine upkeep checks:

| Gauge Sort | Frequency | Particular Duties |

|---|---|---|

| Mechanical | Month-to-month | Cleansing, visible inspection for injury, lubrication (if relevant) |

| Digital | Quarterly | Calibration, visible inspection for injury, battery examine (if relevant) |

“Common upkeep is vital to stopping expensive repairs and making certain correct oil tank measurements.”

Ending Remarks

In conclusion, mastering the artwork of studying oil tank gauges is a vital facet of accountable gasoline administration. By understanding the several types of gauges, decoding their readings, and recognizing potential issues, you may preserve optimum oil ranges, guarantee easy operations, and prioritize security. This complete information equips you with the data and instruments to confidently handle your oil storage wants.

Fast FAQs

What are the widespread causes of inaccurate oil tank gauge readings?

Defective sensors, broken float mechanisms, and electrical points can result in inaccurate gauge readings. A clogged dipstick tube can even trigger inaccurate dipstick readings.

How typically ought to I examine my oil tank gauge?

Common checks are essential, particularly earlier than lengthy journeys or when experiencing uncommon efficiency points. A superb rule of thumb is to examine your gauge earlier than every use.

What are the protection precautions to take when working close to an oil tank?

All the time prioritize security. Put on acceptable protecting gear, guarantee correct air flow, and preserve a protected distance from the oil tank. By no means work alone, and be aware of potential hazards.

What are the totally different items of measurement used on oil tank gauges?

Frequent items embody gallons, liters, and typically barrels. All the time consult with the particular gauge’s unit markings.