Learn how to use a swamp cooler motor for bicycle? This exploration delves into the intriguing chance of repurposing a swamp cooler motor for bicycle propulsion. We’ll study the potential advantages and disadvantages, the required modifications, and the security issues concerned on this unconventional strategy to bicycle design. Understanding the nuances of adapting this distinctive motor sort will permit for a deeper appreciation of its potential and the challenges that should be addressed.

This complete information will stroll you thru the method of choosing an appropriate motor, adapting it for bicycle use, designing a protected and efficient energy transmission system, and implementing the modifications in a manner that optimizes effectivity and security. We’ll cowl vital design issues, security precautions, and troubleshooting steps to make sure a profitable venture. Past the bicycle, we’ll additionally discover the broader potential of this motor for different makes use of.

Introduction to Swamp Cooler Motors and Bicycle Functions: How To Use A Swamp Cooler Motor For Bicycle

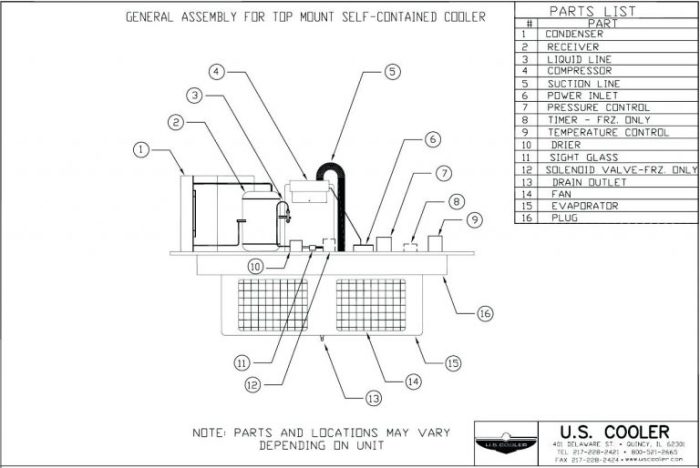

Swamp cooler motors, usually ignored within the realm of bicycle mechanics, current an intriguing avenue for exploring different energy sources. These motors, sometimes present in evaporative cooling techniques, possess distinctive traits that may be adaptable for bicycle propulsion. This exploration delves into the potential of leveraging these motors for bicycle functions, contemplating their benefits, disadvantages, and inherent challenges.Swamp cooler motors are pushed by a compressor, usually utilizing a small AC motor to facilitate the evaporative cooling course of.

Understanding their fundamental perform is essential for assessing their suitability for bicycle use. They sometimes generate a comparatively low quantity of energy in comparison with extra typical bicycle motors, however their inherent simplicity would possibly make them an fascinating different for particular functions.

Primary Perform of a Swamp Cooler Motor

Swamp cooler motors, in contrast to typical bicycle motors, function on a distinct precept. They make the most of a compressor to pressure air via a water-soaked filter, making a cooling impact. The motor’s perform is straight linked to the cooling course of. This differs considerably from the direct rotational energy output of a standard bicycle motor.

Bicycle Mechanics Related to Motor Integration

Integrating any motor right into a bicycle requires cautious consideration of the bicycle’s current parts and mechanics. Key issues embody the motor’s energy output, the bicycle’s body design, and the out there house for mounting and wiring. The bicycle’s gearing system should be suitable with the motor’s output to make sure environment friendly energy switch. An in depth understanding of torque and pace traits is important.

Potential Benefits and Disadvantages

- Benefits: Swamp cooler motors could provide a novel strategy to different bicycle propulsion because of their relative simplicity and potential cost-effectiveness, particularly if parts may be repurposed from current swamp coolers. The quiet operation of some swamp cooler motors may very well be advantageous in sure conditions.

- Disadvantages: The restricted energy output of swamp cooler motors, usually geared in the direction of a particular cooling capability, would possibly show inadequate for typical bicycle speeds and gradients. The excessive upkeep necessities of the water-cooling mechanism might pose a problem for dependable operation over time. The distinctive design of a swamp cooler motor might also make integration into a typical bicycle body much less simple than utilizing a motor designed for biking.

Potential Challenges in Adaptation

Adapting a swamp cooler motor for bicycle use presents a number of challenges. The motor’s design could indirectly translate to bicycle propulsion, requiring important modifications. The motor’s energy output may not be ample for constant acceleration and hill climbing. Integrating the motor into the bicycle’s current construction might additionally current important mechanical challenges. Making certain clean operation and correct energy transmission is paramount to profitable integration.

Examples of Present Bicycle Designs

At present, there aren’t any widespread examples of bicycles using swamp cooler motors for propulsion. Whereas the idea has not been absolutely explored within the realm of bicycle design, its potential software stays a subject for future exploration. The distinctive traits of swamp cooler motors might result in fascinating, doubtlessly unconventional bicycle designs.

Comparability of Swamp Cooler Motors with Different Motor Sorts

| Characteristic | Swamp Cooler Motor | Electrical Motor (Brushless DC) | Inside Combustion Engine |

|---|---|---|---|

| Energy Output | Low | Medium to Excessive | Medium to Excessive |

| Upkeep | Probably Excessive (water cooling) | Low | Medium |

| Price | Probably Low (repurposing) | Medium | Medium to Excessive |

| Effectivity | Variable (relying on design) | Excessive | Variable |

| Noise Stage | Probably Low | Low | Excessive |

Motor Choice and Modification

Selecting the best swamp cooler motor and adapting it for bicycle use requires cautious consideration of a number of key components. This course of entails understanding the motor’s specs, making crucial modifications, and making certain compatibility with the bicycle’s mechanical system. A well-selected and correctly modified motor can considerably improve the bicycle’s efficiency and performance.

Key Specs for Motor Choice

Swamp cooler motors fluctuate of their energy output, voltage, and RPM (rotations per minute). Figuring out these specs is essential for figuring out the motor’s suitability for bicycle propulsion. Elements like the specified pace, terrain, and rider weight will affect the suitable motor selection. For example, a motor with greater RPMs may be very best for hilly terrain, whereas a motor with a better energy output may very well be appropriate for heavier riders.

Cautious consideration of those components will guarantee a balanced and environment friendly energy supply system.

Mandatory Modifications for Bicycle Adaptation

A number of modifications are sometimes wanted to adapt a swamp cooler motor for bicycle use. These modifications guarantee correct integration with the bicycle’s current parts and the motor’s efficient functioning. This contains changes to the motor’s mounting, wiring, and kit system.

Potential Parts Requiring Modification

- Motor Housing: The motor housing would possibly want alterations for safe and steady mounting on the bicycle body.

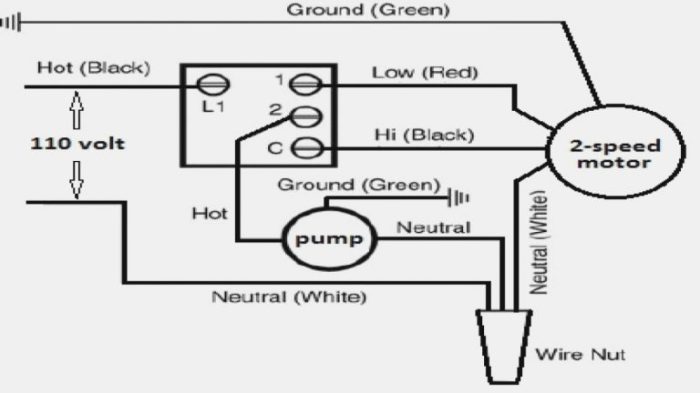

- Wiring: The motor’s wiring system could require changes to attach it to the bicycle’s battery and management system. Acceptable connectors and wiring harnesses needs to be used to make sure electrical security and effectivity.

- Gear System: The motor’s output shaft would possibly want a gearbox or different gearing mechanism to match the bicycle’s chain or belt drive system.

- Mounting Brackets: Customized brackets could also be required to securely connect the motor to the bicycle body, making certain structural integrity and stopping vibrations.

- Management System: A management system is required to handle the motor’s operation, together with pace changes and stopping mechanisms.

Motor Energy Output and Voltage Specs

The ability output and voltage of the motor are important issues. The ability output needs to be ample to propel the bicycle on the desired pace and deal with the terrain. For example, a motor with a better energy output will likely be extra appropriate for steeper hills or heavier riders. The voltage ought to match the bicycle’s battery system to make sure correct operation and forestall harm.

Matching the motor’s voltage to the battery system is vital for a protected and efficient setup.

Mounting the Motor to the Bicycle Body

Totally different mounting strategies can be utilized to connect the motor to the bicycle body. Some widespread strategies embody direct mounting, utilizing a bracket system, or integrating the motor into the body’s design. The chosen mounting methodology ought to think about the motor’s dimension, weight, and the bicycle’s body construction. Cautious planning and exact implementation of the mounting system are important for a dependable and sturdy setup.

Instance Desk of Motor Adaptation Steps

| Step | Description |

|---|---|

| 1 | Disassemble the swamp cooler motor to entry inside parts. |

| 2 | Design and fabricate mounting brackets to connect the motor to the bicycle body. |

| 3 | Join the motor’s wiring to the bicycle’s battery and management system. |

| 4 | Combine the motor’s output shaft with an appropriate gear system to match the bicycle’s drive system. |

| 5 | Check the motor’s performance and make crucial changes to make sure optimum efficiency. |

Energy Transmission and Management Techniques

Harnessing the facility of a swamp cooler motor for a bicycle requires cautious consideration of how the motor’s rotational vitality is transferred and managed. This part particulars the assorted strategies for transmitting energy from the motor to the bicycle’s drivetrain, in addition to choices for regulating the motor’s pace and path. Understanding these techniques is essential for making a dependable and environment friendly energy system.

Energy Transmission Strategies

A number of strategies exist for transferring the rotational vitality from the motor to the bicycle’s wheels. The optimum selection relies on the motor’s traits, the specified bicycle configuration, and the general design objectives.

- Chain Drive: A sequence drive is a standard and sturdy methodology for transmitting energy. A sequence connects the motor’s output shaft to a sprocket, which is then linked to the bicycle’s rear wheel sprocket. This methodology is dependable, environment friendly, and available, making it a well-liked selection. Nevertheless, chain upkeep, lubrication, and put on may be components to contemplate.

A well-maintained chain drive can present constant energy switch.

- Belt Drive: Belt drives provide a smoother, quieter operation in comparison with chain drives. A toothed belt connects the motor to a pulley system, which in flip drives the bicycle’s rear wheel. Belt drives are typically low-maintenance, however the choice of an appropriate belt is vital for applicable energy switch. The sturdiness of the belt can fluctuate primarily based on the fabric and high quality.

- Direct Drive: In a direct drive system, the motor’s output shaft is straight coupled to the bicycle’s rear wheel hub. This methodology eliminates the necessity for intermediate parts like chains or belts, doubtlessly simplifying the design and decreasing friction. Nevertheless, direct drive techniques may be extra complicated to implement and might not be appropriate for all motor varieties.

Velocity and Route Management, Learn how to use a swamp cooler motor for bicycle

Controlling the pace and path of the motor is important for a practical bicycle. A number of strategies can obtain this.

- Variable Velocity Management: A variable pace controller permits the consumer to regulate the motor’s pace. These controllers sometimes make the most of digital parts to control the facility delivered to the motor, permitting for clean acceleration and deceleration. Any such management is especially useful for attaining completely different speeds for various terrains or consumer preferences. Totally different controllers provide completely different ranges of precision and responsiveness.

- Reversing Mechanism: To vary the motor’s path of rotation, a reversing mechanism is important. This mechanism sometimes entails a motor controller with particular settings for ahead and reverse operation. The controller manages the present movement to the motor, permitting for easy switching between instructions.

Examples of Appropriate Energy Transmission Techniques

Examples of appropriate energy transmission techniques rely upon the particular motor and bicycle configuration.

- Bicycle with a sequence drive: A swamp cooler motor, with its output shaft linked to a sequence sprocket, can be utilized to drive the rear wheel via a typical bicycle chain and cassette. The system would possible require a variable pace controller to handle acceleration and deceleration.

- Electrical Bicycle with a belt drive: A swamp cooler motor coupled with a belt drive can create a quiet and environment friendly energy system for an electrical bicycle. The belt’s clean operation and minimal upkeep make it appropriate for one of these software. The motor controller is important for controlling pace and path.

Limitations of Energy Transmission Strategies

Every energy transmission methodology has potential limitations.

- Chain Drive: Chain drives can expertise put on and require lubrication, doubtlessly affecting efficiency over time. Cautious choice of the chain and sprockets is important for sustaining effectivity.

- Belt Drive: Belt drives would possibly expertise slippage below heavy hundreds or if the belt will not be correctly tensioned. The lifespan of the belt can fluctuate relying on its high quality and use situations.

- Direct Drive: Direct drive techniques may not be appropriate for all swamp cooler motors, because the motor’s torque and rotational pace could not completely match the bicycle’s wants. The motor’s dimension and weight are additionally vital components.

Energy Transmission Techniques Comparability

| Energy Transmission System | Professionals | Cons |

|---|---|---|

| Chain Drive | Strong, environment friendly, available, comparatively cheap | Requires upkeep, lubrication, and put on can happen |

| Belt Drive | Clean operation, low upkeep, quieter than chain drives | Potential for slippage below heavy load, costlier than chain drive in some instances |

| Direct Drive | Simplified design, doubtlessly lowered friction | Might not be appropriate for all motor varieties, complexity in implementation |

Connecting the Motor to the Bicycle’s Drivetrain

A step-by-step process for connecting the motor to the bicycle’s drivetrain is detailed beneath.

- Assess the bicycle’s drivetrain: Fastidiously examine the bicycle’s present drivetrain parts, being attentive to the chain, cassette, and rear wheel hub.

- Choose suitable parts: Select sprockets, chains, or belts that match the motor’s output specs and the bicycle’s current drivetrain. Think about the bicycle’s wheel dimension, gearing, and desired torque.

- Mount the motor: Securely mount the motor to the bicycle body utilizing applicable brackets and {hardware}. Guarantee correct alignment and stability.

- Join the facility transmission system: Join the chosen energy transmission system (chain, belt, or direct drive) to the motor’s output shaft and the bicycle’s rear wheel.

- Set up the controller: Set up the motor controller in accordance with the producer’s directions. Join the controller to the motor and the battery.

- Check the system: Fastidiously take a look at the system for clean operation, making certain that the motor capabilities as anticipated. Alter the controller as wanted for optimum efficiency.

Design Concerns and Security

Changing a swamp cooler motor for bicycle use requires cautious consideration to security and sturdiness. A poorly designed or applied conversion can result in accidents, harm to the bicycle, and even harm. Thorough planning and adherence to security pointers are paramount.Designing for security and sturdiness is vital to stop potential hazards. This contains making certain the motor is securely mounted, the facility transmission system is strong, and the general design is steady.

A well-engineered conversion permits for protected and satisfying use.

Significance of Security Precautions

Correct security precautions are important when working a modified bicycle. These precautions assist forestall accidents and preserve management. Utilizing a modified bicycle with a swamp cooler motor requires changes to dealing with and consciousness of potential hazards. An intensive understanding of those precautions is important for protected operation.

Potential Hazards Related to Swamp Cooler Motors on Bicycles

A number of potential hazards are related to utilizing a swamp cooler motor on a bicycle. These hazards embody: the elevated weight of the motor, the added complexity of the facility transmission system, and the potential for electrical points. Cautious consideration of those components throughout the design and modification course of is essential. Improper set up can result in a sudden lack of management.

Influence of Motor Weight on Bicycle Dealing with

The added weight of the motor can considerably influence the bicycle’s dealing with traits. A heavier motor will have an effect on the middle of gravity, doubtlessly making the bicycle much less steady and responsive. This impact may be mitigated by strategic motor placement and cautious choice of parts. Testing and changes to the bike’s geometry will likely be crucial for efficient dealing with.

Optimizing Motor Effectivity for Bicycle Use

Optimizing the motor’s effectivity for bicycle use is important for maximizing efficiency and minimizing energy consumption. Elements like gear ratios, motor pace, and energy transmission effectivity all affect the system’s total effectiveness. Utilizing applicable gearing and cautious choice of motor RPM will help optimize the effectivity of your complete system. Consideration of things similar to load, pace, and terrain are key to attaining optimum efficiency.

Security Tips and Precautions for Modified Bicycles

- Safe Mounting: The motor should be securely mounted to the bicycle body utilizing applicable mounting {hardware} and methods to stop slippage and vibrations. Utilizing high-quality, appropriately sized fasteners and securing the motor with bracing, the place wanted, will forestall vibrations and harm. A appropriately designed mounting system ensures the motor stays firmly in place throughout operation.

- Satisfactory Energy Transmission: The ability transmission system should be sturdy sufficient to deal with the motor’s output with out failure. Be certain that the chain, sprockets, and every other parts within the transmission system are appropriately sized and able to dealing with the facility output. The selection of chain, gears, and sprockets ought to account for the motor’s energy and the rider’s weight.

- Electrical Security: Guarantee all electrical connections are correctly insulated and guarded. All wiring needs to be routed to keep away from chafing or contact with transferring elements. Utilizing applicable electrical connectors and defending the wires with tubing can guarantee the security of the system.

- Correct Load Evaluation: The bicycle’s load capability needs to be evaluated with the added weight of the motor and any equipment. The bike’s construction and parts needs to be appropriate for the elevated load. Overloading can result in harm and questions of safety.

- Common Inspection: Common inspection and upkeep of the modified bicycle are essential to determine potential points earlier than they grow to be main issues. Common checks for put on and tear and correct lubrication of transferring elements can considerably enhance the security and longevity of the transformed bike.

| Security Guideline | Precautions |

|---|---|

| Safe Mounting | Use applicable {hardware}, bracing, and safe fastening methods. |

| Energy Transmission | Choose parts applicable for the motor’s output. |

| Electrical Security | Insulate all wiring and defend from contact with transferring elements. |

| Load Evaluation | Consider the bicycle’s capability with the added weight. |

| Common Inspection | Test for put on and tear, lubrication, and potential points. |

Implementation and Testing

Placing your swamp cooler motor-powered bicycle collectively is an thrilling step. This part particulars the meeting course of and essential testing procedures to make sure a clean and protected trip. Cautious consideration to element throughout implementation and thorough testing will assist assure the bicycle’s reliability and longevity.

Meeting of the Modified Bicycle

The meeting course of entails rigorously integrating the swamp cooler motor into the bicycle body. Begin by mounting the motor to an appropriate location on the body, making certain correct alignment with the facility transmission system. Safe the motor with applicable mounting {hardware}, guaranteeing its stability throughout operation. Join the motor wires to the facility supply and management system, confirming appropriate polarity to stop harm.

Subsequently, set up the facility transmission parts, similar to chains, belts, or gears, making certain they’re correctly aligned and tensioned. Closing steps embody putting in any crucial security tools and verifying the performance of your complete system earlier than driving.

Testing Procedures for Correct Performance

Thorough testing is important to validate the motor’s efficiency and the general system’s reliability. Start with static checks to guage the motor’s operation with none load. Observe the motor’s pace and torque traits, and hear for any uncommon noises or vibrations. These preliminary checks assist determine potential mechanical points earlier than loading the system. Subsequently, carry out load checks to find out the motor’s efficiency below precise driving situations.

Strategies for Testing Motor Efficiency

A number of strategies can be utilized to guage the motor’s efficiency. Measure the motor’s pace and torque utilizing applicable instruments. Observe the motor’s effectivity by measuring the facility output in comparison with the vitality enter. Report these knowledge factors and analyze them to know the motor’s conduct. A vital side is assessing the motor’s capacity to take care of a constant pace below various hundreds.

Monitor the system’s efficiency below completely different situations, together with inclines and completely different rider weights.

Potential Points Throughout Testing and Troubleshooting

Throughout testing, numerous points would possibly come up. Issues like incorrect wiring connections or insufficient energy provide can result in motor malfunction. Insufficient alignment of the facility transmission system or free parts can lead to inefficient energy switch and extreme put on. If the motor runs at an inconsistent pace or produces uncommon noises, examine the connections and mechanical parts for any points.

Measuring and Adjusting Motor Efficiency

Adjusting the motor’s efficiency entails fine-tuning the facility transmission system and management parts. Alter the chain or belt stress to optimize energy switch. Modify the management system to regulate the motor pace and torque in accordance with the specified efficiency traits. Experiment with completely different management settings to seek out the optimum steadiness between pace, torque, and effectivity.

Abstract of Check Procedures and Anticipated Outcomes

| Check Process | Anticipated Final result |

|---|---|

| Static take a look at (no load) | Motor operates easily at anticipated pace and torque with no uncommon noises or vibrations. |

| Load take a look at (inclines) | Motor maintains constant pace and torque even on inclines, demonstrating its capacity to deal with load variations. |

| Velocity and torque measurement | Motor pace and torque stay inside anticipated ranges. |

| Effectivity measurement | Motor effectivity meets the goal specs. |

| System consistency take a look at | The system maintains steady efficiency and pace throughout numerous situations. |

Different Makes use of and Functions

Harnessing the quiet effectivity of a modified swamp cooler motor opens up a wealth of prospects past bicycle propulsion. This adaptable motor, with its sturdy development and comparatively low upkeep, can discover new life in numerous mechanical techniques. Exploring these different functions not solely extends the motor’s lifespan but in addition unlocks its potential for various and sensible makes use of.Swamp cooler motors, because of their inherent traits, are well-suited for functions requiring constant, low-speed torque.

Their compact design and talent to be simply built-in into current techniques make them a horny selection for quite a few tasks.

Potential Functions in Different Transportation Techniques

This part explores the applicability of modified swamp cooler motors in different transportation contexts. These motors generally is a appropriate choice for specialised automobiles, significantly in situations the place excessive torque at low speeds is essential.

- Small-scale agricultural automobiles: The flexibility to offer regular energy for duties like tilling small plots or transporting gentle hundreds makes them appropriate for smaller agricultural tools. The motors’ low pace operation is well-suited for these functions, offering constant energy for the required duties.

- Private transport gadgets: Consideration may be given to modifying the motor to be used in small, private transport automobiles similar to hand-powered carts or small, specialised automobiles. This would possibly contain adapting the gear ratios and energy transmission techniques for optimum efficiency within the focused software.

- Specialised industrial instruments: Swamp cooler motors may be appropriate for instruments needing regular low-speed torque, similar to small-scale grinding wheels or specialised material-handling gadgets. The constant torque output makes them very best for duties the place precision and reliability are key.

Adaptation for Different Mechanical Techniques

This part particulars the method of adapting the motor to be used in numerous mechanical techniques. Key issues embody gear ratios, management techniques, and energy transmission mechanisms.

- Gearbox integration: The motor’s output shaft may be coupled with a gearbox to regulate the pace and torque traits for particular duties. This can be a vital step in adapting the motor for numerous functions, offering a variety of output traits.

- Management techniques: Implementing easy management techniques similar to variable-speed drives (VSDs) can present exact pace management and allow the motor for use in techniques requiring dynamic changes to energy output. This permits for better flexibility within the software of the modified motor.

- Energy transmission mechanisms: Adapting the facility transmission mechanisms, similar to chains, belts, or sprockets, permits the motor to be coupled to numerous output parts. Correct choice of the transmission mechanism is important for environment friendly energy switch.

Suitability for Particular Machines

The inherent traits of swamp cooler motors make them appropriate for particular machine functions. This part will discover examples of their suitability and the way modifications may be made.

- Small-scale pumps: The motor’s low pace, excessive torque traits are well-suited for pumping functions, similar to small water pumps for irrigation or drainage. The constant energy supply ensures dependable operation in these functions.

- Small-scale mills: The motor’s capacity to provide constant torque at low speeds makes it appropriate for producing small quantities of energy for off-grid or backup functions. This may contain adapting the motor’s output to drive a generator, offering a dependable energy supply.

- Building tools: The motor’s sturdy design and talent to ship constant torque make it a viable choice for smaller development duties. This will likely contain diversifications to the motor housing and mounting for sturdiness and ease of integration into current tools.

Abstract Desk of Different Functions

| Utility | Modification Factors | Suitability |

|---|---|---|

| Small-scale agricultural tools | Gearbox, management system | Excessive |

| Small-scale pumps | Energy transmission, management system | Medium |

| Small-scale mills | Generator coupling, management system | Excessive |

| Private transport gadgets | Gearbox, energy transmission | Medium |

| Specialised industrial instruments | Gearbox, mounting | Medium |

| Building tools | Mounting, housing | Low |

Closing Conclusion

In conclusion, adapting a swamp cooler motor for bicycle use presents a captivating engineering problem. Whereas providing the potential for distinctive propulsion techniques, the method calls for cautious consideration of motor choice, modification, energy transmission, and security. This information gives a radical framework to navigate this course of, from preliminary design to ultimate testing and implementation. The potential for different functions additional expands the scope of this repurposing effort.

Query & Reply Hub

What are the widespread points encountered throughout motor adaptation?

Widespread points embody mismatched voltage and energy output specs, insufficient mounting options resulting in instability, and improper energy transmission inflicting lowered effectivity.

What are some security precautions to take whereas engaged on the modified bicycle?

Guarantee correct insulation, use applicable security gear (gloves, eye safety), and take a look at the system totally earlier than driving to stop electrical shocks or mechanical malfunctions.

What are the alternate options to utilizing a swamp cooler motor for bicycle?

Different choices embody utilizing electrical motors, inside combustion engines, or human-powered techniques like conventional bicycle gears.

How can I optimize the motor’s effectivity for bicycle use?

Optimization entails choosing a motor with applicable energy output, rigorously designing the facility transmission system, and making certain minimal friction throughout operation.