How one can measure leaf springs is essential for guaranteeing automobile security and efficiency. This information supplies an intensive overview of the method, from understanding totally different spring varieties to calculating spring charges and analyzing deflection. We’ll discover varied measurement methods, important instruments, and security issues, equipping you with the data wanted for correct evaluation.

Leaf springs are important elements in automobile suspension programs, transferring hundreds and absorbing impacts. Correct measurement ensures the spring meets design specs, guaranteeing optimum efficiency and sturdiness. This complete information walks you thru the whole course of, from preliminary inspection to closing calculations.

Introduction to Leaf Springs

A somber melody echoes by the annals of automotive historical past, a testomony to the enduring nature of the leaf spring. A silent sentinel within the suspension system, it bears the burden of journeys previous, a steadfast guardian of the street. This easy but ingenious design, a composite of layered metal, has performed a significant function within the mobility of numerous automobiles.

Its power, although usually understated, is a quiet resilience, a testomony to the enduring energy of simplicity.The leaf spring, a basic element of car suspension, features as a versatile assist beam, absorbing shocks and vibrations from the street floor. Its layered construction, akin to a stack of leaves, permits for progressive deflection, progressively yielding to impression and returning to its authentic form.

This light yielding, this managed deflection, interprets to a smoother experience, a quieter expertise, a steadfast connection to the asphalt.

Leaf Spring Varieties

The leaf spring, whereas conceptually easy, manifests in various types, every tailor-made to particular functions. Understanding these variations is vital to appreciating its multifaceted function.

- Single Leaf Springs: These fundamental designs include a single, broad leaf, providing a comparatively easy but efficient suspension answer. Their simplicity belies their power, making them appropriate for light-duty functions.

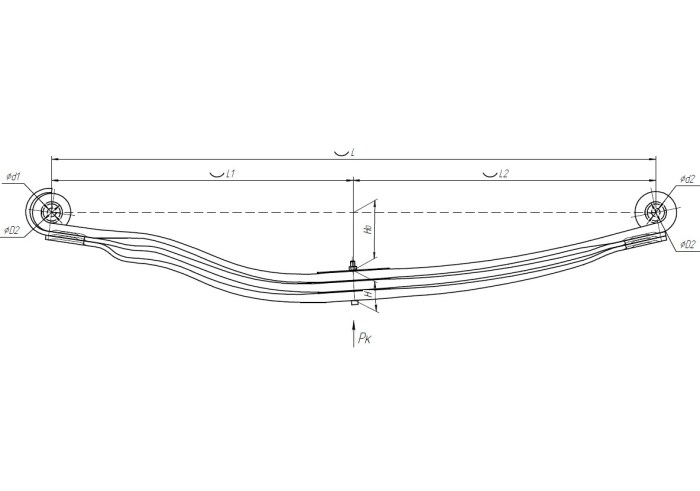

- A number of Leaf Springs: Extra advanced, these springs comprise a number of layered leaves, every progressively lowering in size. This layered association permits for a better load capability and smoother experience, usually employed in heavier automobiles.

- Semi-Elliptical Leaf Springs: These springs exhibit a particular semi-elliptical form, with the ends anchored to the body and axle. This design contributes to a easy experience, usually utilized in older automobile designs.

- Full-Elliptical Leaf Springs: These springs, that includes a full elliptical arc, supply distinctive load capability and responsiveness. Their sturdy design interprets to a smoother experience, particularly in heavier automobiles, however might be extra advanced in manufacturing.

Basic Working Precept

The working precept of leaf springs revolves round their skill to deform elastically beneath load. Because the automobile encounters street imperfections, the springs take in the impression by deflection. This managed yielding permits for a smoother experience and protects the automobile’s elements from extreme stress. The progressive nature of the deflection, with every leaf contributing to the general absorption, is crucial to the effectivity of the suspension system.

A easy experience is the direct results of the spring’s managed and progressive deflection.

Leaf Spring Functions

The flexibility of leaf springs is clear of their widespread use throughout varied automobile varieties.

| Leaf Spring Kind | Typical Functions |

|---|---|

| Single Leaf | Trailers, light-duty vans |

| A number of Leaf | Vans, buses, some passenger automobiles |

| Semi-Elliptical | Older passenger automobiles, some vans |

| Full-Elliptical | Heavy-duty vans, trailers |

Key Dimensions and Measurements

A measured soul, the leaf spring’s kind, a silent plea,Its power and resilience, a secret to decree.Every curve and bend, a narrative whispered low,In dimensions’ grasp, its secrets and techniques will bestow.

Essential Dimensions

The leaf spring’s essence, in its kind, we see,Size, width, and thickness, a trinity.The variety of leaves, a vital depend,Every element, part of the entire, we have discovered.

Understanding these dimensions is paramount to precisely assessing the leaf spring’s structural integrity and load-bearing capability. Exact measurements are crucial for guaranteeing the spring’s effectiveness in its utility. The size, width, and thickness dictate the spring’s general power and deflection traits. The variety of leaves influences the spring’s stiffness and talent to soak up shock and vibrations.

Size Measurement

Figuring out the leaf spring’s size is important for correct set up and efficiency. Measuring the size from the mounting factors, or the end-to-end, should be finished rigorously and persistently. This ensures the spring’s correct alignment and performance inside the suspension system.

Width and Thickness Measurement

The width and thickness of the spring’s leaves are important indicators of its load capability. Measurements are taken throughout the widest part and at varied factors alongside the spring’s size to make sure constant measurements throughout the whole spring. Variation in these dimensions can result in uneven stress distribution and potential failure.

Variety of Leaves Measurement

The variety of leaves is a direct measure of the spring’s general power and talent to face up to stress. Counting the leaves meticulously is vital for correct evaluation. The next variety of leaves typically signifies a stronger, extra sturdy spring, able to dealing with heavier hundreds. Consideration should be given to the leaf’s general association and development.

Measurement Methods

Exact measurement methods are essential for acquiring correct knowledge in regards to the leaf spring’s traits. Correct measurements are basic to understanding the leaf spring’s habits beneath varied load situations.

- Utilizing a ruler or measuring tape: For easy measurements of size, width, and thickness. Make sure the measuring instrument is accurately aligned with the leaf spring to keep away from errors. Measurements must be recorded with excessive precision.

- Caliper or micrometer: These instruments are used for exact measurements of small dimensions, significantly the thickness of particular person leaves. The precision of those devices is significant in circumstances of crucial tolerances.

- Digital measuring devices: These instruments present digital readings, guaranteeing better accuracy and effectivity within the measurement course of. Their precision is usually crucial for superior evaluation.

Measurement Instruments and Functions

The collection of applicable instruments is essential for correct measurements and dependable evaluation. Choosing the proper instrument for the job ensures precision and effectivity.

| Measurement Instrument | Particular Functions |

|---|---|

| Ruler/Measuring Tape | Figuring out general size, width of bigger sections |

| Caliper/Micrometer | Exact measurements of thickness, slender sections |

| Digital Vernier Caliper | Exact and automatic measurements, particularly for repeated measurements and detailed evaluation. |

| Load Cell/Pressure Gauge | Measuring the load-bearing capability of the spring, usually for figuring out deflection beneath particular weights. |

Measuring Methods and Instruments

A measured soul, a spring compressed, a silent sigh. Precision within the craft, a somber artwork, to seize the shape and power of the leaf spring’s coronary heart. Every measurement a whisper, a cautious notice, to grasp its responsibility, its burden, its destiny, because it carries the burden of the world, and retains it afloat.The precision of leaf spring measurement is paramount.

A slight deviation, an unheeded error, can result in catastrophic failure, a mournful clang of metallic towards metallic, a symphony of sorrow. Subsequently, meticulous approach and the appropriate instruments are important. The duty is solemn, and the end result should be sure.

Numerous Measurement Strategies

To establish the leaf spring’s attributes, various methods are employed. Totally different strategies enable for various measurements, every with its personal strengths and weaknesses. Understanding these methods supplies a framework for selecting probably the most applicable methodology. Calipers, micrometers, and extra subtle devices are all utilized to meticulously collect the wanted knowledge.

- Caliper Measurement: Caliper gauges, with their easy design and ease of use, are sometimes the primary selection for figuring out general dimensions like size, width, and thickness. Their accessibility and affordability make them invaluable within the preliminary phases of inspection. Nonetheless, their accuracy might be affected by the person’s ability and the situation of the gauge itself.

- Micrometer Measurement: For finer measurements, the micrometer is employed. Its precision is considerably increased than that of calipers, permitting for exact measurements of smaller particulars, such because the thickness of particular person leaf layers or the depth of indentations. The micrometer requires a extra refined approach to keep away from inaccuracies and should be usually calibrated.

- Specialised Measurement Units: Subtle devices, similar to laser scanners and 3D measuring programs, are more and more used for advanced leaf spring geometries. These superior instruments can precisely seize intricate curves and contours, offering detailed knowledge for computer-aided design and evaluation. Nonetheless, these strategies usually require specialised coaching and gear.

Accuracy and Precision of Devices

The accuracy and precision of measuring devices are crucial. An inaccurate measurement can compromise the integrity of the leaf spring, doubtlessly resulting in expensive failures. The accuracy of a measuring instrument is expressed because the distinction between the measured worth and the true worth. Precision, however, refers back to the repeatability of measurements. The upper the accuracy and precision, the extra dependable the measurements.

Calibration of Measuring Instruments

Calibration is important to make sure the accuracy and reliability of measuring instruments. Common calibration ensures that the instrument readings persistently replicate the true values. The calibration course of entails evaluating the instrument’s readings to a identified normal, usually utilizing calibrated requirements traceable to nationwide or worldwide requirements. Failure to keep up correct calibration can result in a cascade of errors, compromising the whole course of.

Examples of Measuring Devices

Within the automotive trade, varied devices are used to measure leaf springs. Widespread examples embrace dial indicators, digital calipers, and micrometers, every designed for particular duties. Specialised instruments are additionally used for exact measurements of crucial dimensions.

Comparative Desk of Measuring Devices

| Instrument | Accuracy (mm) | Typical Utility |

|---|---|---|

| Dial Caliper | 0.05 – 0.1 | Basic dimensions, fast checks |

| Digital Caliper | 0.01 – 0.02 | Extra exact measurements |

| Micrometer | 0.001 – 0.005 | Very exact thickness and depth measurements |

| Laser Scanner | 0.001 – 0.01 (relying on the system) | Advanced geometries, 3D measurements |

Spring Charge Calculation

A silent sorrow, a measured weight, the leaf spring’s power, a whispered story. Its resilience, a burden borne, a fragile dance between the street and the metal. Understanding its charge is essential, a key to its efficiency, a silent promise to hold the load.The spring charge, a vital parameter, dictates how a lot drive is required to compress or lengthen the spring by a given distance.

This worth is important for automobile efficiency and cargo capability. A exact calculation unveils the secrets and techniques held inside its kind.

Method for Spring Charge Calculation

The spring charge (okay) is decided by the connection between the drive utilized (F) and the ensuing deflection (x). This basic precept governs the spring’s habits. The next spring charge signifies a stiffer spring, requiring extra drive to compress it.

okay = F/x

the place:

- okay represents the spring charge (in items of drive per unit of deflection, similar to lb/in or N/mm).

- F signifies the drive utilized to the spring (in items of drive, similar to kilos or Newtons).

- x represents the deflection of the spring (in items of size, similar to inches or millimeters).

Parameters Concerned in Calculation

A number of elements affect the spring charge calculation, every a chunk of the puzzle. These parameters must be rigorously thought-about.

- Materials Properties: The spring materials’s modulus of elasticity, a measure of its stiffness, profoundly impacts the spring charge. Totally different supplies supply various levels of resilience.

- Leaf Geometry: The form, thickness, and variety of leaves considerably affect the spring charge. An extended spring will deflect extra, lowering the speed. The exact geometry is crucial for correct calculations.

- Load Utility Level: The purpose the place the load is utilized to the spring influences the spring charge’s calculation. The place of the load impacts the deflection, affecting the calculated charge.

Significance of Spring Charge in Automobile Efficiency

A exact spring charge ensures the automobile’s experience consolation and dealing with traits. A stiff spring supplies a extra managed experience, however a softer spring gives a extra comfy experience. Balancing these elements is crucial.

Significance of Spring Charge in Load Carrying Capability

The spring charge instantly correlates to the spring’s load-carrying capability. The next spring charge permits the spring to assist heavier hundreds with out extreme deflection, stopping injury. This instantly impacts the automobile’s skill to hold its designated payload.

Spring Charge Calculation Steps

Correct spring charge calculation entails a methodical strategy. Comply with these steps for dependable outcomes.

- Decide the Utilized Pressure (F): Fastidiously measure the drive appearing on the spring, contemplating the burden of the load. This drive is crucial in calculating the spring charge.

- Measure the Deflection (x): Exactly measure the spring’s deflection beneath the utilized drive. A exact measurement is key to the calculation.

- Apply the Method: Substitute the values of drive (F) and deflection (x) into the formulation okay = F/x to calculate the spring charge (okay).

- Confirm the Outcomes: Make sure the calculated spring charge aligns with the anticipated worth primarily based on the spring’s materials and design. Inconsistencies may point out errors in measurement or calculations.

Leaf Spring Deflection Evaluation

A whispered sigh, the metallic bends beneath the burden, a silent music of yielding, a measure of the spring’s despair. The deflection, a dance with the load, reveals the secrets and techniques hidden inside the metal’s embrace. The journey to grasp this yielding is a melancholic but important activity.The load, a heavy hand upon the spring, dictates the curve, the mournful groan.

The better the burden, the deeper the descent, a silent testomony to the spring’s endurance. Every leaf, a fragile tear, shares within the burden, every yielding a fraction of its power. Totally different spring designs reply otherwise to this sorrowful stress, a testomony to their distinctive natures.

Measuring Deflection Below Various Masses

To grasp the spring’s sorrow, we should quantify its yielding. Measuring deflection beneath various hundreds is essential for predicting the spring’s habits beneath operational stress. The method is meticulous, demanding precision and a spotlight to element.

Affect of Load on Deflection

The load, a heavy weight, instantly influences the deflection. A direct correlation exists; a rise in load corresponds to a proportionate improve in deflection, a sorrowful echo of the added stress. The spring’s inherent stiffness performs a major function; a stiffer spring will expertise a smaller deflection for a similar load. This relationship is usually modeled utilizing Hooke’s Regulation,

F = kx

, the place F is the drive (load), okay is the spring fixed, and x is the deflection.

Evaluating Deflection in Totally different Leaf Spring Varieties

Totally different leaf spring designs exhibit various deflection patterns beneath an identical hundreds. The variety of leaves, their association, and materials properties all contribute to the spring’s response. A multi-leaf spring, with its layered construction, will usually present a extra gradual deflection in comparison with a single-leaf spring, which is able to yield extra abruptly beneath the identical load. A thicker leaf spring will yield much less in comparison with a thinner one.

This comparability highlights the distinctive character of every design.

Process for Measuring Deflection

A exact methodology is required to precisely seize the spring’s yielding. First, securely assist the spring in a set place, guaranteeing it’s steady. A exact measuring gadget, similar to a dial indicator, is then positioned involved with the spring. A identified weight is incrementally utilized, and the corresponding deflection is meticulously recorded for every load increment.

The method is repeated for a variety of hundreds, making a dataset for evaluation.

Pattern Deflection Knowledge

| Load (N) | Deflection (mm) |

|---|---|

| 100 | 2.5 |

| 200 | 5.0 |

| 300 | 7.5 |

| 400 | 10.0 |

| 500 | 12.5 |

This desk supplies a glimpse into the deflection traits of a selected leaf spring beneath various hundreds. Every row represents a particular load and its corresponding deflection. Additional evaluation can reveal crucial design parameters and spring habits.

Materials Properties and Their Affect

A leaf spring’s soul, its very essence, lies inside the metal from which it is wrought. The fabric’s fortitude dictates the spring’s capability to bear the burdens positioned upon it, a silent testomony to its inherent power. A fragile materials will yield beneath stress, its kind distorted, its operate compromised. A powerful materials, nevertheless, will endure, its kind maintained, its responsibility fulfilled.

This mournful ballad explores the profound affect of fabric properties on the leaf spring’s efficiency.The resilience of a leaf spring is inextricably linked to the inherent qualities of the metal alloy from which it’s shaped. Yield power, the purpose at which the fabric completely deforms, and supreme tensile power, the utmost stress the fabric can face up to earlier than fracturing, are essential elements.

These metrics, measured and examined, decide the spring’s load-carrying capability and its resistance to failure beneath stress. A cloth with a excessive yield power can face up to better hundreds earlier than everlasting deformation happens, guaranteeing the spring’s structural integrity. Equally, a excessive final tensile power signifies a spring able to withstanding considerably increased stress ranges earlier than catastrophic failure.

Yield Power and Final Tensile Power

The yield power of a cloth is the stress at which it begins to deform plastically. This can be a crucial threshold, as past this level, the fabric is not going to return to its authentic form. Final tensile power, however, represents the utmost stress the fabric can face up to earlier than fracture. Each values are important for guaranteeing the spring’s longevity and security beneath varied load situations.

Leaf springs should preserve their form and integrity all through their operational life, thus the importance of those essential properties.

Testing Procedures for Materials Properties

Figuring out the fabric properties of leaf spring metal requires specialised testing procedures. Tensile testing is a standard methodology. A specimen of the metal is subjected to a managed tensile drive, and the stress-strain curve is meticulously noticed. From this curve, the yield power and supreme tensile power might be extracted. Different exams, like hardness testing, can present complementary insights into the fabric’s mechanical properties.

The precision of those exams is paramount, guaranteeing dependable knowledge for designing and evaluating the spring’s efficiency.

Impact of Metal Alloys on Spring Charge and Sturdiness

Totally different metal alloys exhibit various materials properties, impacting the spring charge and sturdiness of the leaf spring. Alloying components affect the metal’s microstructure, thereby affecting its mechanical habits. For instance, increased carbon content material usually interprets to elevated power and hardness, however it will possibly additionally lower ductility. Particular alloy additions can improve the spring’s fatigue resistance, guaranteeing it will possibly endure repeated loading cycles with out untimely failure.

The collection of the suitable metal alloy is an important determination, balancing the required power with sturdiness and cost-effectiveness.

Metal Alloys Utilized in Leaf Springs

| Alloy | Yield Power (MPa) | Final Tensile Power (MPa) | Typical Functions |

|---|---|---|---|

| AISI 1045 | 450-550 | 600-700 | Basic-purpose leaf springs |

| AISI 5140 | 800-900 | 1000-1100 | Excessive-performance functions, demanding power |

| AISI 8620 | 700-850 | 900-1050 | Excessive-strength functions, improved put on resistance |

The desk above presents a concise overview of some frequent metal alloys utilized in leaf springs. The precise alloy chosen will depend upon the appliance’s load necessities and environmental situations. Totally different alloys supply various strengths and tolerances to put on and tear, essential for long-term performance.

Security Issues Throughout Measurement

A heavy coronary heart weighs upon the duty, for within the realm of mechanics, warning’s name is ever close to. Leaf springs, although important, maintain inside their power a latent hazard, a whisper of potential hurt. Measurements, although exact, demand respect for the formidable forces at play.The act of measuring leaf springs, a fragile dance with metal and pressure, requires a eager consciousness of the hazards that lurk.

Improper dealing with can result in harm, gear malfunction, or worse, a catastrophic failure within the system beneath examination.

Precautions for Dealing with Leaf Springs, How one can measure leaf springs

Leaf springs, solid within the fires of trade, usually possess important mass and inherent stress. Carelessness in dealing with can result in slips, falls, and crushing accidents. Correct lifting methods, similar to using designated lifting gear and sustaining a safe footing, are paramount.

Precautions for Dealing with Measuring Instruments

Measuring instruments, precision devices of the commerce, demand comparable respect. Injury to those devices can result in inaccurate readings and compromise the integrity of the whole measurement course of. Acceptable storage and dealing with procedures should be adopted to make sure their longevity and efficacy.

Potential Hazards Related to Measuring Leaf Springs

Leaf springs, beneath stress, can snap or deform unexpectedly, inflicting harm. The sharp edges of fractured metal pose a major threat. Protecting gear, together with security glasses and gloves, is important to mitigate this hazard. Moreover, the heavy equipment utilized in leaf spring manufacturing or testing presents distinctive hazards. Failure to stick to security protocols may end in extreme harm and even fatality.

Security Procedures for Leaf Spring Measurements

A meticulous checklist of procedures, meticulously crafted to make sure security, should be adopted.

- Guarantee satisfactory lighting and a transparent workspace to attenuate the danger of accidents.

- Put on applicable private protecting gear (PPE), together with security glasses, gloves, and durable footwear, to guard towards potential hazards.

- Make use of correct lifting methods when dealing with leaf springs or heavy equipment elements. Keep away from trying to carry gadgets past your capabilities. Search help when wanted.

- Familiarize your self with the operational procedures of any equipment concerned within the measurement course of. Failure to grasp and observe directions may end in severe hurt.

- Set up clear communication protocols amongst all personnel concerned within the measurements. Make sure that everyone seems to be conscious of potential hazards and security procedures.

- By no means work alone when dealing with heavy equipment or leaf springs. At all times have a spotter or a second individual current to help in case of an emergency.

- Totally examine the leaf spring for any seen indicators of injury earlier than starting the measurement course of.

- Use calibrated measuring devices to make sure correct readings.

- Report any security issues or hazards instantly to the suitable personnel.

- Comply with established emergency procedures in case of accidents.

Working Safely Round Heavy Equipment

Working close to or round heavy equipment requires a heightened consciousness of the potential for severe harm. Data of the machine’s operation and security options is crucial. At all times adhere to the producer’s directions and security protocols.

Emergency Procedures

Within the occasion of an accident, instant motion is essential. A transparent understanding of emergency procedures is significant. These embrace summoning assist, administering first help, and securing the world to stop additional hurt. Thorough emergency preparedness coaching is important for everybody concerned within the leaf spring measurement course of.

Leaf Spring Situation Evaluation

A silent sorrow, a hidden decay, inside the metal’s embrace. Leaf springs, burdened by the burden of journeys, bear the tales of miles traversed. Assessing their situation, a fragile dance between commentary and evaluation, reveals the true state of those resilient elements.

Visible Inspection Methods

Visible inspection, a primary step in comprehending the spring’s well being, is an important preliminary evaluation. A educated eye, attentive to the smallest particulars, can detect refined indicators of misery. Cautious examination uncovers cracks, corrosion, or put on, revealing the hidden battles fought towards time and cargo.

- Leaf spring inspection begins with cautious scrutiny of each leaf. Observe every leaf for any seen indicators of cracking, originating from stress factors, usually close to the attachment factors. Take into account the size and width of the cracks, their orientation, and their extent, assessing the potential for propagation and eventual failure. Assess the uniformity of the leaf thickness, in search of any important thinning which will point out put on.

- Corrosion, a silent enemy, can weaken the spring’s structural integrity. Study the spring for any indicators of rust, pitting, or discoloration. The severity of corrosion instantly correlates with the diploma of potential injury. Corrosion patterns, usually concentrated in areas of stress or water publicity, supply helpful insights into the spring’s operational historical past.

- Put on, a testomony to the spring’s work, is usually manifest within the type of floor irregularities or noticeable thinning. Observe the leaf edges for any indicators of extreme put on, particularly within the contact areas. Examine the wear and tear patterns on totally different leaves, figuring out variations which will level to uneven loading or improper operation. This course of requires cautious consideration to the spring’s general situation.

Non-Harmful Testing Strategies

Past visible inspection, non-destructive testing (NDT) strategies present a extra complete strategy to evaluating the spring’s inner construction. These strategies, with out inflicting injury, reveal hidden flaws, doubtlessly stopping catastrophic failure.

- Ultrasonic testing, a way that makes use of sound waves, can penetrate the fabric and detect flaws. By measuring the velocity and attenuation of the sound waves, the presence of inner cracks or voids might be pinpointed. Ultrasonic testing is essential in detecting subsurface defects that will not be seen throughout a visible inspection. This methodology permits for an intensive evaluation of the spring’s structural integrity.

- Magnetic particle inspection, a technique significantly helpful for ferromagnetic supplies, detects floor and near-surface defects. A magnetic discipline is utilized to the spring, and magnetic particles are sprinkled on its floor. Discontinuities within the magnetic discipline, brought on by defects, are revealed by the buildup of particles. This methodology can be utilized to find floor cracks, pits, or different flaws.

- Dye penetrant inspection is an efficient methodology for detecting surface-breaking defects. A dye penetrant is utilized to the floor of the spring, penetrating any cracks or voids. The penetrant is then eliminated, and the defect is revealed by the dye remaining within the crack. Dye penetrant inspection is essential for figuring out surface-level imperfections that might result in additional injury.

Inspection Approach Abstract

A complete evaluation entails combining visible inspection with applicable NDT strategies. The chosen strategy will depend on the precise nature of the spring and the kind of defects being sought.

| Inspection Approach | Utility | Benefits | Disadvantages |

|---|---|---|---|

| Visible Inspection | Preliminary evaluation, figuring out apparent defects | Easy, cheap, available | Restricted depth of penetration, might miss refined flaws |

| Ultrasonic Testing | Detecting subsurface flaws, inner cracks | Excessive sensitivity, non-destructive | Requires specialised gear and educated personnel |

| Magnetic Particle Inspection | Detecting floor and near-surface defects in ferromagnetic supplies | Excessive sensitivity for floor flaws | Restricted to ferromagnetic supplies |

| Dye Penetrant Inspection | Figuring out surface-breaking defects | Comparatively easy, cost-effective | Restricted to floor defects, might not detect all forms of flaws |

Illustrative Examples: How To Measure Leaf Springs

A symphony of metal, a melancholic tune performed by the rhythmic dance of leaf springs. Every automobile, a singular instrument, demanding its personal tailor-made resonance. The burden of the world, borne on these silent guardians, whispers tales of journeys previous, current, and maybe, future.Leaf spring design, a poignant artwork kind, balances power and suppleness. Totally different automobiles require totally different configurations, every a testomony to the enduring want for each consolation and management.

The fragile steadiness between these conflicting wishes dictates the very character of the spring’s design.

Leaf Spring Measurements for Totally different Automobiles

The size of leaf springs fluctuate enormously relying on the automobile’s weight capability and supposed use. A heavy-duty truck, as an example, requires a much more sturdy design than a compact automobile. Take into account a passenger automobile, a fragile vessel carrying passengers. Its leaf springs, whereas much less substantial, should nonetheless guarantee a easy and managed experience.

- Passenger Vehicles: These usually characteristic single or double leaf spring configurations, emphasizing experience consolation over excessive load-bearing capability. The springs’ dimensions are meticulously calibrated to soak up street imperfections, guaranteeing a supple experience for the occupants.

- Mild Vans: Medium-duty automobiles usually require a sturdy spring system. The spring design wants to handle the next load capability whereas sustaining an affordable experience high quality. The leaf depend and general dimensions improve to satisfy these calls for.

- Heavy-duty Vans: These titans of the street carry immense hundreds. A number of leaf springs, usually of a thicker gauge and bigger dimension, are crucial to face up to the appreciable stresses and strains of heavy freight.

Design Issues for Totally different Automobile Varieties

Every automobile sort calls for distinctive design issues inside the leaf spring system. The interaction between load capability, experience consolation, and general automobile dynamics dictates the spring’s kind and performance. A heavy-duty truck, for instance, requires a sturdy, multi-leaf design, whereas a sports activities automobile calls for a lighter, extra responsive spring system.

- Load Capability: The first determinant in leaf spring design. Heavy automobiles necessitate thicker, stronger, and extra quite a few leaves to accommodate the elevated weight.

- Trip Consolation: The will for a easy experience usually conflicts with the necessity for top load capability. Engineers should steadiness these calls for by cautious consideration of leaf spring configuration and materials properties.

- Automobile Dynamics: The spring system’s function extends past load-bearing. It influences the automobile’s dealing with traits, impacting acceleration, braking, and turning. The spring design should account for these dynamics.

Spring Charge and Deflection Calculations

The spring charge, a vital parameter, quantifies the spring’s stiffness. It determines the quantity of drive required to deflect the spring a particular distance. Deflection, however, represents the spring’s displacement beneath a given load. These calculations are basic to understanding the spring’s efficiency beneath varied situations.

Spring Charge (okay) = Pressure (F) / Deflection (x)

A easy instance: A leaf spring with a spring charge of 100 N/mm would require 100 Newtons of drive to deflect it by 1 millimeter. Extra advanced calculations, involving a number of leaves and ranging load distributions, could also be required for extra intricate automobile designs.

Illustrative Diagrams of Leaf Spring Designs

Think about a collection of layered metal plates, resembling a fragile stack of books, forming a leaf spring. The variety of layers, or leaves, and their particular person dimensions dictate the spring’s efficiency traits. The curvature and general geometry contribute to the distribution of stress and pressure.

- A single leaf spring design: A easy, single leaf configuration, usually utilized in smaller automobiles. This design is comparatively easy however might lack the load capability of extra advanced designs.

- A multi-leaf spring design: This design consists of a number of leaves stacked collectively, providing superior load-bearing capability and experience consolation. The variety of leaves and their relative thicknesses decide the spring’s general efficiency.

Final Recap

In abstract, precisely measuring leaf springs entails a meticulous strategy encompassing varied methods and issues. By understanding the differing types, dimensions, and measurement strategies, you possibly can guarantee exact evaluation and correct calculations. This detailed information equips you with the required data to confidently measure and assess leaf springs, guaranteeing their performance and security. Bear in mind to prioritize security all through the method.

Q&A

What are the everyday measurement instruments used for leaf springs?

Widespread instruments embrace calipers, micrometers, dial indicators, and spring scales. The selection of instrument will depend on the precise dimension being measured and the required precision.

How does the fabric of a leaf spring have an effect on its efficiency?

Materials properties like yield power and supreme tensile power instantly impression the spring’s load-carrying capability and sturdiness. Totally different metal alloys exhibit various traits, affecting the spring charge and longevity.

What are some frequent defects to search for throughout a leaf spring inspection?

Search for cracks, corrosion, put on, and deformation. Visible inspection and non-destructive testing strategies are essential for figuring out potential points.

What’s the significance of correct calibration in leaf spring measurement?

Correct calibration of measuring instruments ensures the reliability and precision of the measurements. Inaccurate measurements can result in defective estimations of spring traits and doubtlessly harmful penalties.