How lengthy does it take for tires to dry rot? This important query unveils a posh interaction of things influencing tire longevity. Understanding the method of dry rot, from its preliminary levels to its devastating penalties, is important for sustaining car security and increasing tire life. This exploration delves into the science behind tire deterioration, the environmental culprits, and the vital steps for prevention and well timed substitute.

Tire dry rot is not a sudden occasion however a gradual course of of decay. Elements like solar publicity, temperature fluctuations, and even storage situations all play a job in how shortly a tire succumbs to this damaging situation. From the preliminary hairline cracks to the intensive deterioration that compromises the tire’s integrity, understanding the timeline and development is paramount to sustaining highway security.

Introduction to Tire Dry Rot

Tire dry rot is a devastating situation that compromises the structural integrity of tires, resulting in untimely failure and potential security hazards. Understanding this course of is essential for car house owners and professionals alike, because it permits for proactive upkeep and ensures the longevity of tires. Correct data permits knowledgeable choices about tire substitute and upkeep, contributing to a safer driving expertise.Tire dry rot happens as a result of degradation of the tire’s rubber compounds.

This degradation is a posh chemical course of pushed by publicity to environmental elements. Over time, the rubber’s molecular construction breaks down, resulting in hardening, cracking, and eventual failure. This course of is accelerated by publicity to daylight, warmth, ozone, and sure chemical compounds. Realizing the mechanisms behind dry rot empowers us to take preventive measures and lengthen the lifespan of our tires.

Definition of Tire Dry Rot

Tire dry rot is the deterioration of a tire’s rubber compounds as a result of publicity to environmental elements. This leads to a weakening and cracking of the rubber, probably resulting in harmful structural failures.

Technique of Dry Rot in Tires

The method of dry rot entails a sequence of chemical reactions triggered by environmental stressors. Ultraviolet (UV) radiation from daylight degrades the rubber’s polymer chains, resulting in crosslinking and chain scission. Warmth accelerates these reactions, inflicting the rubber to develop into brittle and liable to cracking. Publicity to ozone and sure chemical compounds also can trigger oxidative injury, additional weakening the rubber.

The cumulative impact of those elements leads to the seen indicators of dry rot.

Widespread Causes of Dry Rot in Tires

A number of elements contribute to the event of tire dry rot. Extended publicity to daylight is a major contributor, as UV radiation breaks down the rubber molecules. Excessive temperatures exacerbate this course of, growing the speed of chemical reactions. Ozone, a element of polluted air, also can assault the rubber compounds, resulting in fast degradation. Poor storage situations and publicity to chemical compounds also can speed up the method.

Seen Indicators of Dry Rot in Tires

Figuring out the early levels of dry rot is important for stopping accidents. Seen indicators embrace cracking, hardening, and discoloration of the rubber. Small hairline cracks might be indicative of early-stage deterioration, whereas bigger, extra pronounced cracks point out superior levels of dry rot. The rubber might also seem brittle or powdery. Cautious inspection of the tire tread, sidewalls, and any uncovered rubber areas can reveal these telltale indicators.

Phases of Dry Rot Development, How lengthy does it take for tires to dry rot

| Stage | Description | Visible Illustration |

|---|---|---|

| Preliminary Stage | Minor cracking and hardening, normally on the tire’s floor. The rubber might seem barely discolored or uninteresting. | (Think about a tire with very nice, barely noticeable cracks on the tread or sidewall. The rubber seems barely light.) |

| Average Stage | Elevated cracking, probably forming wider fissures or cracks within the rubber. The tire’s rubber may present important discoloration. | (Think about a tire with bigger cracks spanning a number of inches on the tread or sidewall. The rubber seems considerably light or darkened.) |

| Superior Stage | Intensive cracking and crumbling of the rubber. The tire’s construction is compromised, with seen gaps and lack of materials. The rubber might detach or flake off. | (Think about a tire with deep, gaping cracks all through the tread and sidewall. Vital areas of the rubber are lacking or have crumbled.) |

Elements Affecting Dry Rot

Understanding the elements that speed up tire dry rot is essential for extending the lifespan of your tires and making certain security on the highway. By recognizing the environmental pressures and materials properties at play, you can also make knowledgeable choices to proactively forestall this detrimental situation. Correct tire upkeep and storage are important to preserving their integrity and avoiding expensive replacements.Tire dry rot shouldn’t be a random prevalence; it is a consequence of varied interacting elements.

These elements, from the cruel components to the tire’s personal composition, mix to create an surroundings the place rubber degradation thrives. Recognizing these elements empowers you to take preventative measures and safeguard your tires in opposition to this silent enemy.

Environmental Elements Accelerating Dry Rot

Environmental elements considerably affect the speed of dry rot growth. Publicity to sure components creates situations that hasten the breakdown of the tire’s rubber compounds. Daylight, temperature fluctuations, and humidity all play pivotal roles.

- Daylight: Extended publicity to ultraviolet (UV) radiation from daylight is a major driver of dry rot. UV rays break down the polymer chains throughout the tire’s rubber, resulting in cracks, fissures, and in the end, the disintegration of the tire’s construction. For instance, tires parked on rooftops or uncovered to intense daylight in scorching climates degrade considerably quicker than these stored in shaded or cooler environments.

- Temperature: Excessive temperature fluctuations can speed up the growing old course of and promote dry rot. Each intense warmth and freezing temperatures stress the tire’s rubber, inflicting it to crack and lose its elasticity. Tires uncovered to repeated cycles of heating and cooling, reminiscent of these in automobiles regularly parked in direct daylight, are extra vulnerable to dry rot than these stored in secure environments.

- Humidity: Excessive humidity can create an surroundings conducive to mould and mildew development. Whereas indirectly inflicting dry rot, moisture can contribute to the degradation course of and speed up the results of different environmental elements. That is notably noticeable in areas with excessive rainfall and fluctuating temperatures.

Tire Storage Situations and Dry Rot

Correct storage situations can considerably affect the speed of dry rot. Incorrect storage practices can expose tires to damaging components and result in accelerated degradation.

- Storage Location: Tires saved in direct daylight, close to warmth sources, or in humid environments are extra vulnerable to dry rot. Selecting a cool, dry, and shaded location is vital for minimizing publicity to damaging components. For instance, storing tires in a storage with a roof and enough air flow will shield them higher than leaving them uncovered on a deck.

- Storage Supplies: Utilizing applicable storage supplies can defend tires from bodily injury and environmental stressors. Storing tires on pallets or in containers can forestall them from coming into direct contact with the bottom or different components which may trigger injury.

Rubber Compound Results on Dry Rot Resistance

The kind of rubber compound utilized in tire development performs a vital position in figuring out its resistance to dry rot. Completely different formulations supply various ranges of resilience to environmental degradation.

- Rubber Sort: Several types of rubber have various resistance to dry rot. Some rubber compounds include components that improve UV resistance and sturdiness. These compounds are designed to face up to environmental stressors, slowing the degradation course of. For instance, tires utilizing higher-quality, extra resistant rubber compounds can keep their integrity for longer durations beneath harsh situations.

Comparability of Tire Varieties’ Dry Rot Resistance

The resistance of various tire varieties to dry rot varies relying on their development and materials composition. A comparative evaluation gives perception into the elements influencing tire longevity.

| Tire Sort | Dry Rot Resistance (Estimated) | Reasoning |

|---|---|---|

| Excessive-Efficiency Tires | Medium | Typically uncovered to greater temperatures and stress as a result of efficiency calls for. |

| All-Season Tires | Excessive | Designed for a broader vary of climate situations, usually incorporating enhanced rubber compounds. |

| Winter Tires | Excessive | Typically characteristic particular rubber compounds and designs to face up to excessive chilly and moisture. |

| Truck Tires | Excessive | Sometimes engineered with sturdy compounds and bolstered buildings for prolonged use and heavy masses. |

Penalties of Dry Rot: How Lengthy Does It Take For Tires To Dry Rot

Driving on tires compromised by dry rot is akin to driving on a ticking time bomb. The insidious nature of this deterioration weakens the tire’s structural integrity, making it vulnerable to catastrophic failure. Understanding the potential hazards is essential for sustaining secure driving practices and stopping accidents. This information empowers you to proactively handle this problem, safeguarding each your security and your funding in your car.The deterioration brought on by dry rot is not merely an aesthetic concern; it profoundly impacts the tire’s skill to carry out its vital perform: sustaining contact with the highway floor.

This compromised contact results in lowered dealing with, elevated danger of skidding, and in the end, a higher likelihood of accidents. Neglecting this important facet can have far-reaching and devastating penalties.

Potential Hazards of Driving on Dry Rotted Tires

Driving on tires with important dry rot poses a critical menace to security. Cracked and brittle tire parts, particularly sidewalls and treads, severely diminish the tire’s skill to face up to stress and keep correct contact with the highway. This vulnerability interprets instantly into the next danger of sudden tire failures, probably resulting in lack of management and accidents. The implications lengthen past the speedy hazard to the motive force and passengers, encompassing potential property injury and authorized liabilities.

Compromised Tire Integrity and Power

Dry rot profoundly weakens the tire’s structural integrity. The deterioration of rubber polymers results in the formation of microscopic cracks and fissures. These structural flaws progressively compromise the tire’s skill to help the load of the car and face up to highway stresses. This gradual weakening is commonly undetectable till a vital level is reached, resulting in sudden and catastrophic failures.

A tire weakened by dry rot acts as a structural vulnerability, vulnerable to punctures, blowouts, and in the end, full disintegration beneath load.

Penalties on Tire Efficiency

The efficiency implications of dry rot are important. Diminished grip and dealing with are among the many most crucial penalties. Compromised tread patterns and sidewalls lead to decreased traction on moist or uneven surfaces. This discount in grip interprets to a higher danger of skidding, lack of management, and potential accidents. Moreover, the weakened tire construction impacts dealing with responsiveness, making it more difficult to navigate turns and keep stability at greater speeds.

Examples of Catastrophic Tire Failures Because of Dry Rot

Quite a few reviews element accidents instantly linked to dry rot-induced tire failures. These failures vary from sudden blowouts at excessive speeds to finish tire disintegration beneath braking or acceleration. These incidents underscore the significance of standard tire inspections and well timed replacements to forestall catastrophic occasions. The results of such failures might be extreme, involving damage, property injury, and authorized repercussions.

Results of Dry Rot on Tire Parts

The insidious nature of dry rot impacts totally different tire parts in distinct methods. The next desk illustrates the standard penalties:

| Tire Part | Results of Dry Rot |

|---|---|

| Sidewalls | Cracking, tearing, separation from the tread, lowered help beneath load. |

| Treads | Cracking, chipping, and disintegration of the tread sample, lowered grip. |

| Beads | Brittle, cracked, lowered adhesion to the wheel, potential for separation. |

| Interior Linings | Cracking, deterioration, probably resulting in leaks or blowouts. |

This desk highlights the widespread and detrimental results of dry rot throughout all essential tire parts. Proactive inspection and substitute are paramount for sustaining tire integrity and security.

Prevention and Mitigation

Embarking on a proactive method to tire care is paramount in combating dry rot and making certain the longevity and security of your car. By understanding the essential elements that contribute to dry rot, we will implement preventive measures that safeguard your tires from untimely deterioration. This proactive method not solely extends the lifespan of your tires but in addition mitigates the danger of expensive replacements and potential accidents.

Proactive Tire Storage and Upkeep

Correct tire storage and common upkeep are elementary to stopping dry rot. Tires uncovered to harsh environmental situations, like excessive temperatures, extended daylight, or moisture, are considerably extra vulnerable to this damaging course of. A managed storage surroundings, ideally a cool, dry space shielded from direct daylight, can considerably scale back the danger of dry rot.

Tire Rotation and Inflation Stress

Tire rotation is essential for even put on and tear. Common rotation, sometimes each 5,000 to 7,000 miles, distributes the stress and friction throughout the complete tire tread, stopping uneven put on that may compromise the tire’s structural integrity and hasten dry rot. Moreover, sustaining the proper inflation stress is important. Incorrect inflation can result in localized stress on particular tire areas, contributing to untimely put on and potential dry rot.

At all times seek the advice of your car’s proprietor’s guide for the really helpful inflation stress.

Visible Inspection for Dry Rot

Common visible inspections are indispensable for figuring out dry rot in its early levels. Early detection permits for immediate motion and prevents additional deterioration, probably saving you important monetary sources and stopping security hazards. Early indicators of dry rot, like cracking, splitting, or hardening of the tire’s sidewall or tread, ought to immediate speedy consideration.

Step-by-Step Tire Inspection Information

- Preparation: Collect a flashlight and a notepad. Select a well-lit space for inspection.

- Visible Evaluation: Look at the complete tire, together with the sidewalls, tread, and any seen markings. Word any uncommon modifications in texture, coloration, or floor integrity. Search for cracks, splits, or bulges.

- Particular Focus: Pay shut consideration to areas of the tire that will expertise higher stress or publicity to the weather. This will likely embrace the perimeters of the tread, the sidewalls, and the areas across the tire’s mounting factors.

- Documentation: Document your observations. Take notes on any anomalies and use photos if doable. This detailed document is important for monitoring the situation of your tires over time.

- Skilled Analysis: If you happen to discover important indicators of dry rot, seek the advice of a professional tire skilled for a complete evaluation and applicable suggestions.

Restore and Alternative

Embarking on a journey to revitalize your tires, the realm of restore and substitute calls for a discerning method. Ignoring dry rot shouldn’t be an choice; it is a path towards compromised security and probably catastrophic penalties. Understanding the nuances of restore versus substitute is paramount for safeguarding your journey and making certain an enduring funding in your automobiles.

Feasibility of Repairing Dry Rot Harm

Repairing minor dry rot injury is typically doable, but it surely’s a posh endeavor. The effectiveness of a restore relies upon closely on the extent and site of the injury. Floor-level cracks and small areas of decay could also be repairable, however important injury usually requires an entire substitute.

Limitations of Repairing Vital Dry Rot Harm

Vital dry rot injury renders restore ineffective and probably harmful. The compromised structural integrity of the tire makes restore unreliable and unsustainable. Trying to patch a severely weakened tire is akin to patching a sinking ship; the hassle is in the end futile and dangers a sudden catastrophic failure. Moreover, the underlying injury usually extends past the seen cracks, making a community of unseen weaknesses which can be troublesome to handle by restore.

Comparability of Completely different Tire Restore Strategies

A number of tire restore strategies exist, every with distinctive limitations and effectiveness ranges. Patching, plugging, and recapping are a few of the commonest approaches. Patching entails making use of a patch over a puncture or small gap. Plugging is used for bigger holes, the place a plug is inserted. Recapping entails changing the tire’s tread, which is commonly carried out on tires with intensive put on however not dry rot.

The efficacy of those strategies for dry rot injury is extraordinarily restricted. Primarily, these strategies goal various kinds of injury, and dry rot is essentially totally different. Repairing dry rot injury shouldn’t be the identical as patching a puncture.

Significance of Changing Tires with Vital Dry Rot Harm

Changing tires with important dry rot injury is essential for security. The weakened rubber construction poses a considerable danger of sudden tire failure, resulting in lack of management, accidents, and extreme accidents. A compromised tire can result in sudden and unpredictable occasions on the highway. This isn’t a matter of comfort, however a matter of life and security.

The danger of a sudden blowout or uncontrolled skid is simply too excessive to disregard. Preventive measures, reminiscent of common inspections and immediate replacements, are vital to making sure secure journey.

Steps for Changing Tires with Dry Rot

- Visible Inspection: Fastidiously examine the tire for seen indicators of dry rot, reminiscent of cracks, splits, or powdery disintegration. This preliminary step is important in assessing the general situation of the tire.

- Skilled Analysis: Seek the advice of a professional tire technician for an expert evaluation. Tire professionals can present correct diagnoses and recommend the most effective plan of action, making certain the substitute is carried out appropriately.

- Tire Choice: Select tires that meet the car’s specs and security requirements. Think about elements like load capability, pace ranking, and tread sample to make sure optimum efficiency.

- Set up: Have an expert set up the brand new tires. Correct set up ensures appropriate steadiness and alignment, which is essential for optimum tire efficiency and car dealing with.

- Security Checks: Conduct post-installation security checks to make sure the brand new tires are correctly mounted and balanced. That is important for secure driving and long-term tire efficiency.

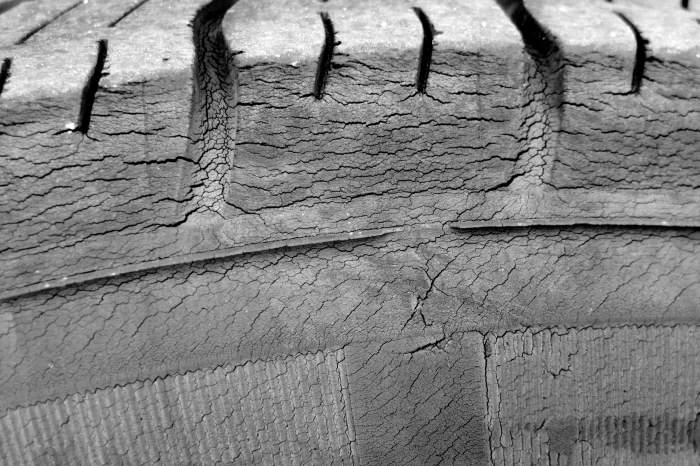

Visible Illustration of Dry Rot

Unveiling the insidious nature of dry rot requires a eager eye and understanding of its visible manifestations. Tire dry rot is not a sudden, dramatic occasion; it is a sluggish, degenerative course of, usually progressing subtly over time. This insidious degradation, if left unchecked, can result in catastrophic tire failure, compromising security and probably inflicting extreme accidents. Let’s now delve into the intricate visible cues that sign the presence of dry rot.

Figuring out Dry Rot by Look

Tire dry rot is not merely a matter of discoloration; it manifests in a large number of the way. Visible inspection, coupled with data of the patterns, will help you detect the presence of dry rot early. Cautious remark is essential to stopping a critical incident.

Completely different Visible Traits of Dry Rot

Dry rot presents itself with varied visible traits. A telltale signal is the cracking or crumbling of the rubber compound. This cracking can seem as nice traces, resembling a spiderweb sample, or bigger, extra pronounced fissures. The rubber might also develop into brittle, simply flaking off or breaking into small items beneath minimal stress. These modifications should not restricted to the tread; they will lengthen to the sidewalls and even the interior layers of the tire.

Dry Rot Patterns

Dry rot patterns are sometimes indicative of the severity and length of the injury. Early levels may reveal delicate cracking, showing like a community of nice traces. As the method progresses, these traces widen and deepen, forming extra important cracks. In superior levels, the rubber might develop into nearly fully disintegrated, with massive sections flaking away. The sample itself, whether or not it is a radial crack or a extra diffuse, random community, gives useful insights into the potential extent of the issue.

Phases of Dry Rot Development, How lengthy does it take for tires to dry rot

The next desk gives a visible illustration of the levels of dry rot development, illustrating the gradual deterioration of the tire’s integrity:

| Stage | Description | Visible Traits |

|---|---|---|

| Early | Preliminary indicators of cracking and hardening. | Positive, spiderweb-like cracks are seen, predominantly on the tread. The rubber feels stiffer than regular. |

| Intermediate | Cracks improve in dimension and depth. | The cracks widen, changing into extra pronounced. Rubber might present indicators of flaking or crumbling. Some areas may exhibit a uninteresting, grayish-white discoloration. |

| Superior | Vital deterioration of the rubber construction. | Massive cracks span throughout the tread and probably lengthen to the sidewalls. The rubber seems brittle and crumbles simply. The tire might have important bulges or depressions. |

Illustrative Examples of Dry Rot

Think about a tire with nice cracks that resemble a spiderweb. This means an early stage of dry rot. Distinction this with a tire exhibiting massive, gaping cracks that reach to the sidewalls. That is a sophisticated stage requiring speedy substitute. Moreover, think about a tire that shows a uninteresting, grayish-white discoloration, together with the presence of flakes or crumbly rubber.

This signifies important deterioration, highlighting the significance of standard inspections.

Correct tire upkeep and early detection of dry rot can save lives and forestall expensive repairs.

Tire Life Expectancy and Dry Rot

Mastering tire longevity is essential for secure and environment friendly driving. Understanding the interaction between tire age, driving situations, and susceptibility to dry rot empowers you to make knowledgeable choices about tire upkeep and substitute. Proactive measures considerably lengthen tire life, decreasing surprising bills and making certain optimum efficiency.

Relationship Between Tire Age and Dry Rot

Tire age is a major determinant of dry rot vulnerability. Older tires, particularly these uncovered to extended solar, warmth, and moisture, exhibit elevated susceptibility to degradation. The growing old course of weakens the tire’s rubber compounds, making them extra liable to cracking, splitting, and in the end, dry rot. This vulnerability escalates with every passing yr, impacting structural integrity and compromising security.

Affect of Driving Situations on Tire Life Expectancy

Driving situations considerably affect tire lifespan. Frequent publicity to excessive temperatures, harsh climate, and aggressive driving kinds speed up put on and tear. For instance, driving in extraordinarily scorching climates could cause fast deterioration of rubber compounds, resulting in untimely dry rot. Conversely, driving in colder climates won’t present speedy dry rot however can nonetheless weaken the rubber over time.

Moreover, heavy masses and frequent sharp braking or acceleration cycles place extra stress on the tire construction, probably hastening dry rot.

Elements Affecting Tire Lifespan in Phrases of Dry Rot

A number of elements affect a tire’s lifespan in relation to dry rot. These embrace materials composition, manufacturing high quality, and environmental situations. Tires made with higher-quality, extra sturdy rubber compounds will resist dry rot higher. Moreover, correct storage and dealing with can mitigate the results of environmental stressors like UV radiation, warmth, and moisture. Common tire rotations and correct inflation pressures additionally contribute to prolonged tire life.

Common Lifespan of Completely different Tire Varieties and Susceptibility to Dry Rot

The typical lifespan of a tire varies relying on its kind and meant use. A complete evaluation reveals that passenger automotive tires sometimes have a lifespan of 5-7 years, whereas gentle truck tires can final 6-8 years. Nonetheless, these are simply averages, and precise lifespan might be considerably affected by elements like driving habits, environmental situations, and tire upkeep.

A devoted inspection is essential to evaluate the situation of a tire.

| Tire Sort | Common Lifespan (Years) | Susceptibility to Dry Rot (Low/Medium/Excessive) |

|---|---|---|

| Passenger Automotive | 5-7 | Medium |

| Gentle Truck | 6-8 | Medium |

| Excessive-Efficiency | 4-6 | Excessive |

| All-Terrain | 6-7 | Medium |

Process for Figuring out Tire Age and Potential Dry Rot Dangers

A scientific method to assessing tire age and dry rot danger entails a number of steps.

- Visible Inspection: Fastidiously study the tire sidewalls for cracks, splits, or indicators of hardening. Search for any discoloration, which could possibly be indicative of extreme UV publicity.

- Date Stamp Verification: If current, seek the advice of the date stamp on the tire sidewall to establish the manufacturing date. Remember that this date represents when the tire was produced, not when it was put in.

- Skilled Evaluation: Consulting a professional mechanic can present an correct evaluation of the tire’s situation, together with any potential dry rot. They will study the tire’s construction and supply insights into its remaining lifespan.

- Driving Situations Evaluation: Think about the driving situations the tire has endured. Frequent publicity to excessive temperatures or aggressive driving can speed up the growing old course of.

Closure

In conclusion, the time it takes for tires to dry rot is not a set quantity; it is a dynamic course of influenced by quite a few elements. Correct upkeep, together with common inspections, optimum storage, and understanding the interaction of environmental elements, can considerably lengthen a tire’s lifespan. Realizing the indicators, potential penalties, and preventative measures permits drivers to proactively safeguard their security and their automobiles.

Finally, recognizing the delicate indicators of dry rot and appearing promptly is essential to making sure secure and dependable driving.

High FAQs

How can I inform if my tires are displaying indicators of dry rot?

Seen cracking, crumbling, or hardening of the rubber are telltale indicators. Search for nice hairline cracks, particularly across the sidewalls and tread. If the rubber feels unusually stiff or brittle, it is a robust indicator.

What are the commonest causes of tire dry rot?

Extended solar publicity, fluctuating temperatures, and improper storage are main contributors. Age can be a major issue; older tires are extra liable to dry rot.

Can dry rot be repaired, or is substitute all the time vital?

Minor dry rot may be repairable, however important injury usually necessitates substitute. Patching or different repairs might not handle the underlying structural weak spot brought on by superior dry rot.

How usually ought to I examine my tires for dry rot?

Common visible inspections throughout tire rotations, particularly in high-wear areas just like the tread, are essential. Examine tires each 3-6 months, or extra regularly if uncovered to harsh situations.