The way to align engine to propeller shaft is essential for optimum efficiency and longevity of marine or industrial equipment. Improper alignment can result in vital points, starting from decreased effectivity to catastrophic failures. This complete information delves into the intricacies of engine-propeller alignment, from elementary rules to superior troubleshooting methods.

Understanding the assorted forms of engines and their corresponding propeller configurations is significant. This information offers an in depth overview, together with a desk illustrating frequent combos. Correct preparation, utilizing the precise instruments and following meticulous steps, is paramount to reaching correct alignment. The information additionally addresses the security issues inherent in working with equipment.

Introduction to Engine-Propeller Alignment

Exact engine-propeller alignment is paramount for optimum marine and plane efficiency. Neglecting this crucial facet can result in vital operational points, impacting effectivity, security, and finally, profitability. This significant alignment ensures easy energy transmission, minimizing vibration and put on, and maximizing the lifespan of each the engine and propeller. Ignoring alignment can result in untimely failure, necessitating expensive repairs and downtime.Engine-propeller misalignment is a typical challenge, typically ignored in routine upkeep schedules.

The implications can vary from delicate efficiency degradation to catastrophic failure, particularly in high-speed purposes. Misalignment can manifest in varied types, together with vibrations, elevated gas consumption, and decreased thrust. Understanding the precise forms of misalignment and the underlying causes is crucial for efficient troubleshooting and prevention. Recognizing the forms of engine-propeller combos utilized in varied purposes is equally important.

Significance of Correct Alignment

Correct alignment of the engine and propeller is essential for environment friendly energy switch. It minimizes vibration, noise, and put on on crucial elements, resulting in longer operational life and decreased upkeep prices. A misaligned system will generate extreme vibrations, probably damaging the engine, the propeller, and the supporting buildings. Diminished thrust and elevated gas consumption are additionally frequent penalties of misalignment.

This finally impacts operational effectivity and will increase working prices.

Potential Penalties of Misalignment

Misalignment leads to a number of undesirable outcomes. These embrace elevated vibration ranges, inflicting untimely put on on bearings, seals, and different elements. Extreme vibration can result in structural harm, probably leading to catastrophic failures. Additional, misalignment reduces the general effectivity of the facility practice. This implies greater gas consumption and decreased thrust output.

The implications of misalignment can range primarily based on the severity and sort of misalignment. As an illustration, a slight misalignment may solely end in elevated vibration, whereas a extra vital misalignment could cause full failure.

Frequent Situations of Misalignment

Misalignment can come up from a number of sources. Improper set up or meeting of the engine or propeller is a frequent trigger. Adjustments within the supporting buildings, like settling of the vessel or plane, also can result in misalignment. Furthermore, put on and tear on elements, notably within the long-term, can contribute to misalignment. Upkeep points and improper torque software also can result in misalignment points.

Kinds of Engine-Propeller Combos

Varied engine and propeller combos exist, every tailor-made to particular purposes and necessities. The choice is determined by components like energy output, velocity, and desired effectivity. Totally different engine varieties and sizes can have various compatibility with particular propeller designs. Understanding the interplay between the engine’s traits and the propeller’s design is important for optimum efficiency.

Desk of Engine-Propeller Configurations

| Engine Kind | Typical Propeller Configuration |

|---|---|

| Inside Combustion Engine (ICE) – Diesel | Variable Pitch Propeller (VPP) or Fastened Pitch Propeller (FPP) |

| Inside Combustion Engine (ICE) – Gasoline | Fastened Pitch Propeller (FPP) |

| Turbine Engine (Jet) | Variable Pitch Propeller (VPP) or Adjustable Angle Propeller |

| Electrical Motor | Fastened Pitch Propeller (FPP) or Managed Pitch Propeller |

Instruments and Gear Required

Mastering engine-propeller alignment calls for precision and the precise instruments. This part equips you with the information to pick and make the most of the important gear, making certain accuracy and security all through the method. Understanding the specs and correct use of those instruments is paramount to reaching a profitable and dependable alignment.

Important Alignment Instruments

Correct engine-propeller alignment hinges on exact measurements and dependable instruments. The fitting instruments be sure that the shaft and propeller are aligned to reduce vibrations and maximize effectivity. A meticulous strategy to deciding on and utilizing these instruments is essential to reaching optimum outcomes.

- Alignment Gauges: These gauges play a pivotal position in figuring out the alignment of the engine to the propeller shaft. Varied varieties exist, every designed for particular purposes and ranges of precision. Correct choice ensures accuracy and avoids misalignment points. As an illustration, dial indicators provide exact measurements, whereas laser alignment methods present a visible illustration of the alignment standing.

Understanding the capabilities of every sort is significant for choosing the suitable gauge to your wants.

- Measuring Tapes and Guidelines: Important for linear measurements, these instruments guarantee correct willpower of distances and supply a basis for calculating misalignment. Excessive-precision measuring tapes and guidelines, with specified tolerances, assure dependable measurements, particularly for crucial shaft alignment.

- Leveling Devices: Making certain a degree mounting floor is prime for correct alignment. Exact leveling devices, comparable to spirit ranges or laser ranges, are essential to get rid of any potential discrepancies brought on by uneven surfaces. Using these devices minimizes errors and maximizes the accuracy of the alignment course of.

- Shaft Alignment Indicators: These indicators exactly measure the axial and radial misalignment between the engine and propeller shaft. Their correct measurements assist diagnose any misalignments, permitting for vital corrections. As an illustration, the usage of dial indicators on the shaft coupling permits for exact measurement of any misalignment.

Alignment Gauge Specs

Totally different alignment gauges have various specs, together with measuring accuracy and capability. Understanding these specs ensures that the chosen gauge is appropriate for the meant software.

| Gauge Kind | Measuring Accuracy | Capability | Software |

|---|---|---|---|

| Dial Indicator | 0.001 inch (0.025 mm) | A number of inches (relying on mannequin) | Exact measurements for minor misalignments |

| Laser Alignment System | 0.0001 inch (0.0025 mm) | A number of ft (relying on mannequin) | Excessive-precision measurements for complicated methods |

| Telescoping Gauge | 0.001 inch (0.025 mm) | A number of ft (relying on mannequin) | Measurements for shaft and coupling misalignment |

Secure Software Dealing with Practices

Secure dealing with of alignment instruments is crucial to stop accidents and make sure the longevity of the gear. All the time adhere to the producer’s directions and comply with established security protocols.

- Correct Storage: Retailer instruments in designated areas to stop harm and guarantee quick access when wanted. Correct storage minimizes the danger of unintentional harm and enhances the longevity of the gear.

- Common Upkeep: Commonly examine instruments for any harm or put on and tear. Sustaining instruments in optimum situation is essential for dependable efficiency and accuracy.

- Applicable Use: Use the proper instrument for the meant software to keep away from harm or inaccurate measurements. Utilizing the proper instrument prevents errors and ensures precision.

Preparation Steps for Alignment

Exact engine-propeller alignment is essential for optimum efficiency and longevity of marine and aviation gear. Neglecting correct preparation can result in misalignment, leading to vital operational points and elevated upkeep prices. A well-defined and executed preparation section ensures correct alignment and reduces the probability of expensive errors throughout the alignment course of.

Cleansing and Inspection Procedures

Thorough cleansing and inspection of the engine and propeller elements are elementary to profitable alignment. This step ensures that every one surfaces are clear and free from particles, enabling correct measurements and exact alignment. Improper cleansing can obscure crucial dimensions, resulting in inaccurate alignment and probably damaging the gear. Correct cleansing methods additionally forestall contaminants from interfering with the alignment course of.

- Engine Parts: Disassemble accessible engine elements to permit for thorough cleansing. Pay shut consideration to areas round mounting surfaces, making certain all traces of grease, grime, and corrosion are eliminated. Use acceptable cleansing brokers and instruments for the precise supplies. For instance, use specialised solvents for aluminum or chrome steel elements to stop harm. Examine for any indicators of wear and tear or harm, comparable to cracks, deformation, or misalignment within the mounting surfaces.

- Propeller Shaft: Clear the propeller shaft, together with the coupling and bearings, utilizing acceptable cleansing brokers and instruments. Totally examine the shaft for any indicators of injury, comparable to cracks, bends, or extreme put on. Be sure that the shaft is free from any international materials that might intrude with the alignment course of. Pay shut consideration to the coupling space for any put on or harm.

This may be sure that the shaft is in correct situation for correct alignment.

- Mounting Surfaces: Clear all mounting surfaces of the engine and the propeller shaft meticulously. Take away any rust, paint flakes, or different particles. Examine these surfaces for any irregularities, comparable to pitting, gouges, or deformations, which may have an effect on alignment accuracy. Utilizing a fine-grit sandpaper to easy tough spots is usually required.

Security Precautions

Prioritizing security throughout engine and propeller preparation is paramount. Accidents may result from improper dealing with of instruments, gear, or chemical compounds. Following security protocols is essential for stopping accidents and gear harm. Adherence to security procedures not solely safeguards personnel but in addition protects the gear into consideration.

- Private Protecting Gear (PPE): Put on acceptable PPE, together with security glasses, gloves, and a respirator, to guard your self from potential hazards. This consists of protecting gear like earplugs and security footwear.

- Energy Instruments and Gear: Flip off energy sources and disconnect gear earlier than engaged on any mechanical elements. Guarantee all instruments are in good working order to stop accidents. Examine energy instruments for any harm or put on earlier than use.

- Cleansing Brokers: Use cleansing brokers and solvents based on the producer’s directions and security knowledge sheets (SDS). Correct air flow is important to keep away from inhaling dangerous fumes. Keep away from mixing cleansing brokers that may generate dangerous gases. All the time comply with security directions offered by the producer for the actual cleansing agent.

- Lifting Gear: Use correct lifting gear when dealing with heavy elements. Have interaction a professional lifting specialist for crucial gear if vital. Seek the advice of the producer’s directions for secure dealing with of the gear.

Pre-Alignment Guidelines

A structured guidelines is significant for making certain all crucial steps are accomplished. An intensive guidelines helps keep away from omissions and ensures that the method is executed methodically. The checklist offers a framework for making ready the engine and propeller for correct alignment.

- Confirm the supply of all required instruments and gear.

- Affirm enough security measures are in place and personnel are adequately educated.

- Disconnect all energy sources to the engine and propeller.

- Totally clear and examine all engine and propeller elements.

- Examine mounting surfaces for irregularities and guarantee their cleanliness.

- Doc any discrepancies or irregularities discovered throughout the inspection.

- Confirm that every one vital documentation, like producer’s specs, is obtainable.

- Affirm all elements are accurately recognized.

- Confirm that every one security procedures have been adopted.

Cleansing Procedures Examples

Correct cleansing procedures range relying on the supplies and elements concerned. A tailor-made strategy ensures that the cleansing course of doesn’t compromise the integrity of the gear.

| Element | Cleansing Process |

|---|---|

| Aluminum Engine Block | Use a gentle detergent resolution and a soft-bristled brush. Rinse completely with clear water. Keep away from utilizing harsh chemical compounds that might corrode the aluminum. |

| Stainless Metal Propeller Shaft | Use a specialised cleaner for chrome steel. Rinse completely with clear water and dry utterly. Don’t use abrasive cleaners that might scratch the floor. |

| Forged Iron Engine Mounts | Use a wire brush or a specialised cleansing instrument to take away rust and particles. Apply a rust-inhibiting resolution to stop additional corrosion. Dry the floor utterly. |

Alignment Procedures

Mastering engine-propeller alignment is essential for optimum efficiency and longevity of your marine or industrial energy methods. Exact alignment minimizes vibration, reduces put on and tear, and maximizes effectivity. This part delves into varied alignment strategies, highlighting their strengths and weaknesses, empowering you to decide on the most effective strategy to your particular wants.

Strategies for Engine-Propeller Shaft Alignment

Correct alignment is paramount in minimizing vibration, noise, and potential harm to the engine and propeller. Totally different strategies cater to numerous wants and situations, permitting for adaptable and efficient options.

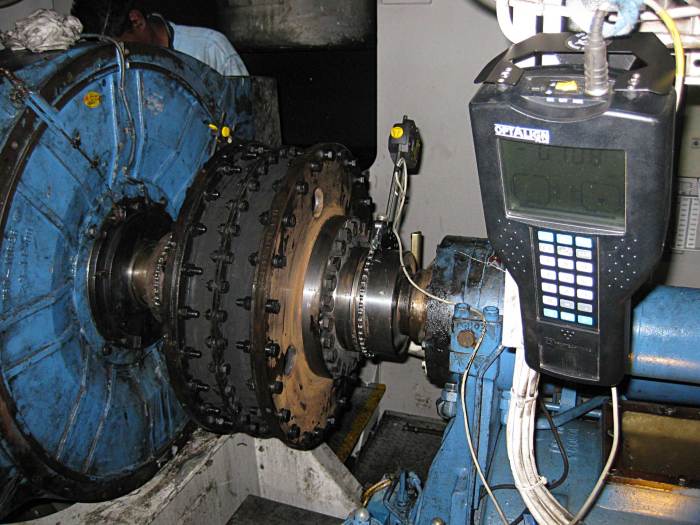

Laser Alignment, The way to align engine to propeller shaft

Laser alignment strategies provide extremely exact alignment options for each easy and complicated methods. This technique makes use of laser beams to measure the distances and angles between the engine and propeller shaft. The laser alignment system offers real-time knowledge, enabling changes to be made as wanted throughout the alignment course of. Refined software program typically accompanies laser alignment gear to course of and interpret the information, automating the alignment course of and producing detailed experiences.

Dial Indicator Alignment

Dial indicator alignment, a conventional and time-tested technique, depends on bodily contact with the shaft to measure misalignment. This technique includes utilizing dial indicators to detect any deviations from the perfect alignment. The dial indicators present direct measurements of the axial, radial, and angular misalignment. Handbook readings may be transformed to specific values by the operator, that are recorded and used for corrections.

String Alignment

String alignment is an easy and sometimes cheap technique, appropriate for preliminary assessments or fast checks. This technique employs a taut string stretched between the engine and the propeller shaft to visually determine potential misalignments. The string technique depends on the visible detection of deviations from the perfect straight line. Whereas it lacks the precision of laser or dial indicator strategies, it offers a fast and economical option to determine gross misalignments.

Alignment Procedures – Detailed Steps

This part offers a complete overview of the steps concerned in every alignment technique. Correct process is important for reaching optimum outcomes.

- Laser Alignment: Set up reference factors on each the engine and the propeller shaft. Place the laser gear based on the producer’s directions. Seize the information, making certain the measurements are taken at a number of factors. Analyze the collected knowledge utilizing the software program. Implement changes as wanted primarily based on the information to attain alignment.

- Dial Indicator Alignment: Place the dial indicators on the engine and the propeller shaft, making certain correct contact. Rigorously measure the misalignment in axial, radial, and angular instructions. File the measurements at a number of factors alongside the shaft. Based mostly on the recorded values, make changes to the engine or the shaft to right the misalignment.

- String Alignment: Make sure the string is taut and straight. Visually examine the string to determine any deviation from a straight line. If deviations are current, pinpoint the placement of the misalignment. Use the noticed deviations as a information to find out the required corrections to the engine or the propeller shaft.

Benefits and Disadvantages Comparability

Every technique has distinctive strengths and weaknesses that should be thought-about.

| Alignment Technique | Benefits | Disadvantages |

|---|---|---|

| Laser Alignment | Excessive precision, automated knowledge seize, detailed experiences | Requires specialised gear, probably costly |

| Dial Indicator Alignment | Comparatively reasonably priced, broadly accessible gear | Handbook measurements, inclined to operator error, time-consuming |

| String Alignment | Easy, cheap, fast evaluation | Low precision, not appropriate for crucial purposes |

Troubleshooting and Error Correction

Mastering engine-propeller alignment includes not simply the process, but in addition the flexibility to diagnose and rectify points. This significant facet ensures optimum efficiency, longevity, and security. Figuring out and addressing alignment issues promptly prevents expensive repairs and downtime.

Potential Alignment Points and Their Causes

Engine-propeller misalignment manifests in varied methods, every with particular root causes. Understanding these permits for focused troubleshooting. Examples embrace shaft runout, eccentric mounting, and improper bearing alignment. Shaft runout, as an example, typically stems from points throughout the manufacturing or meeting means of the shaft itself, or from harm incurred throughout operation. Eccentric mounting is usually the results of poor set up practices or insufficient securing of the engine mounts.

Improper bearing alignment arises from defective set up, misalignment of engine mounts or bedplate, or put on on the bearings.

Troubleshooting Steps for Every Downside

A scientific strategy to troubleshooting is essential. This includes visible inspection, measurement, and testing to pinpoint the basis trigger.

- Shaft Runout: Start with a visible inspection of the shaft for any seen defects, comparable to bends or cracks. Make the most of precision measuring instruments like dial indicators and straight edges to measure the runout. If runout exceeds the producer’s specs, the shaft might require substitute or corrective machining.

- Eccentric Mounting: Visually examine the engine mounts and securing {hardware} for any indicators of looseness or harm. Measure the gap between the engine and the mounting factors. Discrepancies point out improper mounting. Right by tightening fasteners, adjusting mounting factors, or changing broken elements. Correctly torqueing fasteners is essential to stop future motion.

- Improper Bearing Alignment: Study the bearings for extreme put on, harm, or misalignment. Make use of precision devices like dial indicators to find out the alignment of the bearings and shaft. If misalignment is detected, right the positioning of the engine mounts or regulate the bearings, making certain correct clearances.

Essential Corrections for Every Subject

Implementing the precise corrections is significant for restoring alignment and stopping future issues. The corrections should be tailor-made to the precise challenge.

- Shaft Runout Correction: If the shaft is bent, a machine store can straighten it. If cracks are current, substitute is important. Make sure the shaft is inside producer specs for runout after any restore.

- Eccentric Mounting Correction: Re-tighten fasteners, re-adjust the engine mounting factors to make sure correct alignment. Use precision measuring instruments to make sure correct mounting after any changes. If the issue persists, the mounts might must be changed.

- Improper Bearing Alignment Correction: Alter the engine mounting factors or substitute worn bearings. Make sure the bearings have the proper clearance and are accurately lubricated. If the issue is said to the engine bedplate, knowledgeable could also be required for corrective motion.

Figuring out and Correcting Misalignment

A scientific strategy utilizing precision devices ensures correct identification and correction. Thorough documentation of measurements and changes is important for traceability and future reference. This detailed record-keeping additionally aids in avoiding future misalignments.

Troubleshooting Flowchart

| Step | Motion | Consequence |

|---|---|---|

| 1 | Visible inspection for defects | Determine potential points |

| 2 | Measure shaft runout | Decide if runout is inside specs |

| 3 | Measure engine mounting alignment | Decide if mounting is correct |

| 4 | Examine bearing alignment | Determine misalignment in bearings |

| 5 | Right recognized challenge | Obtain correct alignment |

| 6 | Confirm alignment | Affirm correct alignment |

Sustaining Alignment Over Time

Engine-propeller alignment just isn’t a one-time repair. Proactive upkeep is essential for making certain optimum efficiency, longevity, and security. Common inspections and preventative measures are important to protect the alignment achieved throughout the preliminary setup and to mitigate potential points earlier than they escalate. Understanding the significance of routine upkeep and preventative procedures will empower you to take care of the integrity of your engine-propeller system.Preserving the precision of engine-propeller alignment over time is paramount.

Neglecting routine upkeep can result in untimely put on and tear on elements, elevated gas consumption, decreased effectivity, and potential catastrophic failures. A well-maintained system, then again, ensures easy operation, prolonged lifespan, and a discount in sudden downtime.

Routine Inspection Schedule

A strong inspection schedule is significant for sustaining correct alignment. Common checks assist detect potential misalignments early, enabling well timed intervention and stopping vital harm. Frequency of inspections is determined by working situations, environmental components, and the kind of engine and propeller.

Preventative Upkeep Procedures

Preventative upkeep includes a variety of procedures designed to proactively handle potential alignment points. These procedures concentrate on figuring out and mitigating potential issues earlier than they affect the engine-propeller system.

- Visible Inspection: Common visible inspections of the coupling, shaft, and propeller are essential. Search for any indicators of wear and tear, misalignment, or harm. This consists of checking for cracks, distortion, or extreme play. Visible inspection ought to be carried out at common intervals and documented meticulously.

- Torque Measurement: Periodic torque measurements on the coupling are important. Deviations from the required torque values point out potential misalignment. Thorough documentation of those measurements over time permits for early detection of evolving points.

- Vibration Evaluation: Using vibration evaluation instruments can detect delicate vibrations that is probably not instantly obvious by way of visible inspection. These vibrations can typically be a precursor to extra severe misalignment issues.

- Alignment Checks: Reinforce the preliminary alignment checks at specified intervals. Make use of acceptable instruments and methods to substantiate that the alignment stays inside acceptable tolerances. These checks ought to contain each static and dynamic measurements.

Affect of Environmental Elements

Environmental components can considerably affect engine-propeller alignment. Adjustments in temperature, humidity, and vibrations from exterior sources could cause delicate shifts within the alignment over time. Working in excessive environments requires extra frequent and thorough upkeep procedures. For instance, saltwater environments can speed up corrosion and put on, which may have an effect on alignment. Correct sealing and lubrication are important for mitigating these impacts.

Upkeep Process Frequency Desk

| Upkeep Process | Frequency | Description ||—|—|—|| Visible Inspection | Weekly | Examine for indicators of wear and tear, cracks, or misalignment. || Torque Measurement | Month-to-month | Measure coupling torque to determine potential alignment shifts. || Vibration Evaluation | Quarterly | Use vibration evaluation to detect delicate vibrations indicating misalignment. || Alignment Test | Yearly | Conduct thorough alignment checks utilizing acceptable instruments.

|| Element Alternative | As Wanted | Substitute worn or broken elements to take care of correct alignment. |

Security Concerns

Engine-propeller alignment, whereas essential for optimum efficiency and longevity, necessitates meticulous adherence to security protocols. Neglecting these precautions can result in severe damage or gear harm. Understanding and implementing security measures is paramount to a profitable and safe alignment course of.

Vital Security Measures Throughout Alignment Procedures

Secure alignment procedures are paramount. Correct precautions, when diligently adopted, forestall accidents and preserve a secure working atmosphere. This consists of acceptable private protecting gear (PPE) and consciousness of potential hazards.

Significance of Private Protecting Gear (PPE)

Private Protecting Gear (PPE) is a crucial element of any equipment work. PPE serves as a barrier between the employee and potential hazards, considerably decreasing the danger of damage. Applicable PPE should be chosen primarily based on the precise duties and potential risks concerned within the alignment course of. Examples embrace security glasses, listening to safety, and work gloves.

Potential Hazards Related to Misalignment and Improper Procedures

Misalignment and improper procedures can result in a number of hazards. These hazards can vary from minor accidents to severe accidents. For instance, flying particles from improperly secured elements throughout alignment changes could cause eye accidents or lacerations. Moreover, high-stress environments, comparable to these involving heavy equipment, can contribute to slips, journeys, and falls. Unsafe procedures, comparable to utilizing insufficient instruments or making an attempt alignment with inadequate assist, enhance the danger of great hurt.

Security Pointers for Engaged on Equipment

Strict adherence to security tips is significant when engaged on equipment. These tips embody a complete set of procedures designed to mitigate dangers and stop accidents. It is crucial to determine clear procedures, together with shutdown protocols, lockout/tagout procedures, and emergency response plans. Moreover, thorough gear inspections previous to work are crucial to determine and handle potential hazards.

Desk of Security Precautions and Corresponding Security Gear

| Security Precautions | Security Gear | Description |

|---|---|---|

| Machine Shutdown and Lockout/Tagout | Lockout/Tagout gadgets, security tags | Guarantee all energy sources are disconnected and secured earlier than beginning any work. Correct lockout/tagout procedures forestall unintentional energization of the gear. |

| Private Protecting Gear (PPE) | Security glasses, listening to safety, work gloves, security footwear | Applicable PPE ought to be worn to guard in opposition to flying particles, noise, sharp edges, and potential slips or falls. |

| Correct Software Utilization | Right instruments for the duty, calibrated instruments | Utilizing the proper and well-maintained instruments prevents harm to the gear and reduces the danger of damage. Utilizing calibrated instruments ensures accuracy in measurements. |

| Environmental Concerns | Correct lighting, enough air flow, safe working space | Sustaining a secure and managed atmosphere reduces the danger of slips, journeys, falls, and different accidents. Correct lighting enhances visibility, whereas air flow ensures breathable air. |

| Emergency Procedures | Emergency contacts, first assist equipment, evacuation plan | Having available emergency contacts, a primary assist equipment, and a longtime evacuation plan ensures a immediate and efficient response in case of an accident. |

Ultimate Ideas: How To Align Engine To Propeller Shaft

In conclusion, reaching exact engine-propeller alignment requires a scientific strategy encompassing preparation, execution, and ongoing upkeep. This information has offered a radical framework for understanding the method, from figuring out potential misalignment points to implementing efficient troubleshooting methods. By adhering to the Artikeld procedures and security tips, operators can guarantee the graceful and dependable operation of their equipment.

Skilled Solutions

What are the frequent causes of engine-propeller misalignment?

Misalignment can stem from varied components, together with improper set up, put on and tear on elements, and environmental stress. Vibration and uneven strain distribution are additionally potential culprits.

What instruments are important for exact alignment?

Important instruments embrace alignment gauges, dial indicators, measuring tapes, and precision ranges. The particular instruments and their accuracy specs will rely on the dimensions of the mission.

How typically ought to engine-propeller methods be inspected for alignment?

Routine inspections ought to be carried out based on producer suggestions, or as per a pre-determined upkeep schedule. The frequency of inspection is determined by the working situations and the equipment’s utilization.

What are the potential penalties of ignoring alignment points?

Ignoring alignment points can lead to untimely element failure, elevated vibrations, decreased effectivity, and probably catastrophic harm. This may result in expensive repairs and downtime.