Learn how to calculate embedding loss in bolted joint? This complete information delves into the intricacies of bolted joint evaluation, exploring the crucial position of embedding loss in engineering design. Understanding this important facet is crucial for guaranteeing structural integrity and efficiency throughout numerous purposes, from aerospace to automotive.

Bolted joints are ubiquitous in engineering, forming the inspiration of quite a few constructions. Their effectiveness hinges on a exact understanding of embedding loss, a phenomenon that quantifies the deviation of the particular joint efficiency from the theoretical perfect. This information unravels the complicated interaction between geometry, materials properties, and preload to offer a radical framework for calculating embedding loss.

Introduction to Bolted Joint Embedding Loss: How To Calculate Embedding Loss In Bolted Joint

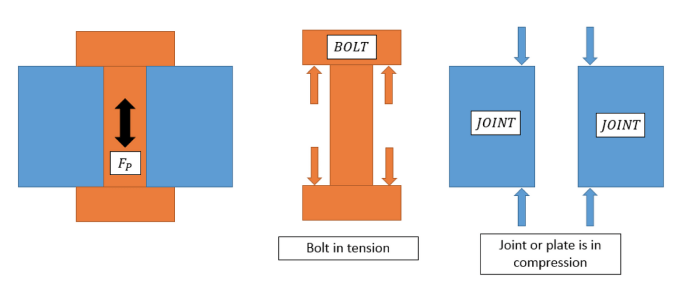

Bolted joints are basic in engineering, offering a robust and dependable connection between elements. Consider them because the glue that holds issues collectively, from bridges to bikes. Their effectivity and sturdiness are essential for structural integrity and efficiency. Understanding the behaviour of those joints, significantly regarding the potential for embedding loss, is important for designing strong constructions.Embedding loss, within the context of bolted joints, refers back to the deformation or injury that happens to the fabric surrounding the fastener gap because the bolt is tightened.

This may end up in a discount of the joint’s total power and stiffness. It is a key think about assessing the long-term reliability of bolted connections. Elements like the fabric properties of the joint members, the geometry of the joint design, and the bolt tightening course of all contribute to the magnitude of this loss.

Geometry and Materials Properties in Bolted Joints

The geometry of the bolted joint, together with the opening diameter, the thickness of the linked components, and the general configuration, considerably influences the embedding loss. Thicker supplies and bigger holes are likely to expertise extra deformation, whereas well-designed joints with exact gap sizing and applicable fillet radii can minimise embedding loss. Materials properties just like the yield power and ductility of the linked supplies additionally play an important position.

Supplies with greater yield power, for instance, will exhibit a better resistance to deformation, mitigating embedding loss. The interplay between the fabric properties and joint geometry is complicated and is dependent upon the particular design parameters.

Comparability of Bolted Joint Varieties

Several types of bolted joints exhibit various susceptibility to embedding loss. A comparability of frequent varieties reveals this.

| Joint Sort | Description | Susceptibility to Embedding Loss |

|---|---|---|

| By-bolted | Fasteners prolong utterly by means of the linked components. | Typically decrease, because the load is distributed extra evenly. |

| Blind-bolted | Fasteners are used to attach components with out full penetration. | Probably greater, because the load is concentrated in a smaller space. Requires cautious design concerns for correct load distribution and materials choice. |

| Lap-jointed | The components are overlapped, and bolts are used to safe the joint. | Susceptibility is dependent upon the overlap and bolt placement; the bigger the overlap, the decrease the potential for embedding loss. |

This desk gives a fundamental overview; extra nuanced assessments rely upon particular design parameters.

Strategies for Calculating Embedding Loss

Proper, so we have established the necessity to quantify embedding loss in bolted joints. Now, let’s crack open the analytical toolkit and see how we will really calculate it. Completely different strategies are suited to completely different situations, and understanding their strengths and weaknesses is vital to getting a dependable outcome.Numerous analytical approaches exist for figuring out embedding loss, every with its personal set of assumptions and limitations.

Selecting the best technique is dependent upon elements just like the complexity of the joint design, the fabric properties, and the specified degree of accuracy. We’ll delve into the main points of FEA and analytical strategies, evaluating their strengths and highlighting their respective purposes.

Finite Factor Evaluation (FEA)

FEA is a strong numerical technique for modelling complicated constructions. It discretises the joint right into a mesh of smaller parts, enabling the simulation of stress and pressure distributions underneath varied loading circumstances. This enables for an in depth evaluation of the embedding course of, accounting for materials non-linearities and geometric complexities. FEA can deal with intricate geometries and materials behaviours not simply captured by less complicated analytical fashions.

Nevertheless, it is computationally intensive and sometimes requires vital experience to arrange and interpret the outcomes.

Analytical Strategies

Analytical strategies present a extra direct and sometimes faster method for estimating embedding loss. They depend on established equations and formulation primarily based on simplified fashions of the joint. These fashions typically assume linear materials behaviour and simplified geometries, however they are often surprisingly correct for sure situations. An important facet is deciding on the suitable mannequin that precisely displays the specifics of the joint sort.

Particular Equations and Formulation

Numerous equations can be found for estimating embedding loss, relying on the joint configuration. For instance, for a easy lap joint, a simplified system primarily based on the shear stress distribution within the bolt and the encompassing materials may be used. A extra complicated system may be required for a extra intricate design, contemplating elements just like the presence of fillets or holes.

Instance for a easy lap joint: Embedding loss (ε) will be estimated as ε = τ / E, the place τ is the shear stress and E is the Younger’s modulus of the fabric.

Extra intricate joint configurations, corresponding to these with a gusset plate, would require extra refined analytical fashions. These would possibly contain calculating the stress concentrations across the bolt gap and the plate edges, making an allowance for the fabric properties and the utilized load.

Comparability of FEA and Analytical Strategies

| Characteristic | FEA | Analytical Strategies ||—|—|—|| Accuracy | Excessive, particularly for complicated geometries | Reasonable to excessive, relying on the mannequin || Computational Price | Excessive | Low || Complexity | Excessive | Reasonable to low || Experience Required | Excessive | Reasonable || Time to Answer | Excessive | Low |

Steps Concerned in Analytical Strategies

Analytical strategies, whereas much less computationally demanding than FEA, nonetheless require cautious execution to attain dependable outcomes. The next steps are typical:

- Outline the joint geometry and materials properties. This includes exactly describing the size of the joint, the kind of materials used, and its mechanical properties like tensile power and Younger’s modulus.

- Choose an applicable analytical mannequin primarily based on the joint sort. Completely different fashions cater to numerous joint configurations.

- Apply the chosen equations and formulation, incorporating the outlined parameters from the earlier steps. This typically includes calculating stress distributions and pressure values.

- Calculate the embedding loss primarily based on the outcomes obtained within the earlier step. This includes calculating the displacement or deformation inside the embedment zone.

Elements Influencing Embedding Loss

Embedding loss in bolted joints, an important metric in structural integrity assessments, is considerably impacted by a large number of things. Understanding these influences is important for correct predictions and efficient design optimisation. An intensive evaluation of those variables permits engineers to tailor designs to minimise potential failure dangers.A complete understanding of embedding loss in bolted joints necessitates a deep dive into the important thing influencing parameters.

This consists of the mechanical properties of the supplies concerned, the geometry of the joint itself, and the exterior loading circumstances. Contemplating these elements allows a extra exact prediction of the embedding loss and enhances the reliability of the structural evaluation.

Preload and Materials Properties

Preload, the preliminary clamping drive utilized to the fastener, performs a pivotal position in embedding loss. Larger preload usually ends in lowered embedding loss, because the clamping drive successfully resists the tendency for the joint elements to separate. Materials properties, such because the yield power and elastic modulus, immediately affect the deformation behaviour of the supplies concerned. Softer supplies exhibit better deformation underneath load, resulting in the next embedding loss in comparison with tougher supplies.

Joint Geometry and Friction/Slip

Joint geometry, encompassing elements like the form of the joint interface and the fastener gap configuration, considerably influences the embedding loss. Complicated geometries can result in stress concentrations, probably exacerbating the embedding loss. Friction between the joint elements, particularly the fastener and the encompassing materials, considerably influences the embedding loss. A better coefficient of friction between the joint surfaces results in a better clamping drive and thus a discount in embedding loss.

Nevertheless, extreme friction may result in stress concentrations and potential put on. Slip, the relative motion between the joint elements, immediately contributes to embedding loss. Slippage within the joint will cut back the effectiveness of the preload and thus enhance embedding loss.

Fastener Traits

Fastener diameter, size, and thread sort are crucial parameters influencing embedding loss. Bigger fastener diameters usually end in the next embedding drive and consequently decrease embedding loss. Conversely, longer fasteners, significantly in instances of excessive hundreds, can improve the embedment resistance, decreasing embedding loss. The thread sort may have an effect on the stress distribution and thus affect the embedding loss.

A well-designed thread can distribute the stress successfully, decreasing the potential for embedding loss.

Materials Mixtures

The interplay between completely different materials combos considerably impacts embedding loss. As an example, a steel-aluminum bolted joint could exhibit greater embedding loss in comparison with a steel-steel joint. That is as a result of differing elastic moduli and yield strengths of the supplies. The mismatch in materials properties can result in non-uniform stress distribution and better deformation, finally leading to the next embedding loss.

Moreover, the differing coefficients of friction between the supplies additionally contribute to this impact. Understanding the particular traits of every materials mixture is crucial for precisely predicting embedding loss.

Experimental Validation and Verification

Validating the calculated embedding loss in bolted joints requires rigorous experimental procedures. This part particulars varied experimental setups, showcasing examples of knowledge evaluation, and demonstrating the correlation between experimental outcomes and the analytical fashions. Correct validation is essential for refining the fashions and guaranteeing sensible applicability in engineering design.

Experimental Setups for Measuring Embedding Loss

Completely different experimental setups are employed to measure embedding loss in bolted joints, every with its personal strengths and limitations. These setups usually contain managed loading circumstances, exact measurement methods, and cautious consideration of the fabric properties of the joint elements. A typical method includes making use of a managed tensile load to the bolted joint whereas concurrently measuring the deformation and pressure inside the joint’s embedding area.

Variations embody utilizing pressure gauges or different displacement sensors for exact measurements of deformation.

Examples of Experimental Knowledge and Evaluation

Experimental information, corresponding to load-displacement curves, pressure distributions, and fracture patterns, are essential for validating the calculated embedding loss. For instance, if a finite factor evaluation predicts a selected embedding loss worth underneath a sure load, the experimental information ought to exhibit an identical development. Analyzing the load-displacement curve helps determine the purpose of yielding or failure, offering insights into the joint’s behaviour.

The pressure distribution inside the embedding area will be in comparison with theoretical predictions from the mannequin, offering a measure of accuracy.

Demonstrating Correlation Between Experimental Knowledge and Analytical Fashions

The correlation between experimental information and the analytical fashions is essential for validating the accuracy and reliability of the fashions. A powerful correlation means that the mannequin precisely represents the bodily phenomena occurring within the joint. As an example, if the experimental load-displacement curve intently matches the curve predicted by the finite factor mannequin, it signifies a great settlement between the mannequin and actuality.

Deviation from the anticipated values could level to areas the place the mannequin wants enchancment or refinement.

Measurement Methods in Experimental Validation

This desk Artikels the completely different measurement methods employed in experimental validation of embedding loss in bolted joints.

| Measurement Method | Description | Benefits | Disadvantages |

|---|---|---|---|

| Pressure Gauges | Measure pressure at particular places inside the joint | Excessive accuracy, gives detailed pressure distribution | Requires cautious placement, potential for interference with the joint |

| Displacement Sensors | Measure displacement of particular factors within the joint | Easy to implement, gives world deformation data | Much less detailed pressure data in comparison with pressure gauges |

| Digital Picture Correlation (DIC) | Measures displacement and pressure fields utilizing digital picture evaluation | Non-intrusive, gives full-field pressure measurements | Requires high-quality photographs, computational assets |

| Acoustic Emission (AE) | Detects acoustic alerts generated throughout the loading course of | Can present early warning of injury initiation | Requires refined evaluation, could indirectly quantify embedding loss |

Functions and Case Research

Understanding embedding loss in bolted joints is paramount for varied engineering disciplines, significantly these involving structural integrity and efficiency underneath load. This data is essential in optimising design parameters, predicting failure factors, and guaranteeing the longevity of elements. An intensive grasp of those elements is important in numerous engineering fields, from aerospace to automotive, the place reliability and security are paramount.

Engineering Functions

Numerous engineering purposes necessitate a meticulous understanding of embedding loss in bolted joints. These embody, however usually are not restricted to, plane constructions, automotive chassis, and strain vessels. Correct prediction of the joint’s load-bearing capability and fatigue life hinges on this understanding. Moreover, understanding embedding loss allows engineers to optimise the design of bolted connections for max effectivity and security.

Case Research

Contemplate a case research involving an plane wing meeting. Vital embedding loss within the attachment factors of the wing to the fuselage may compromise the plane’s structural integrity underneath flight circumstances. The affect of this loss may manifest as untimely fatigue failure and even catastrophic structural collapse. Equally, in automotive purposes, embedding loss in engine mounting bolts can result in vibration points, lowered engine life, and compromised car efficiency.

Engineering Challenges

A number of engineering challenges are immediately addressed by an in-depth understanding of embedding loss. For instance, within the design of high-pressure vessels, precisely modelling the stress distribution across the bolt holes and the impact of embedding loss is crucial for stopping leaks and guaranteeing structural integrity. Furthermore, in aerospace purposes, minimising embedding loss in crucial elements, corresponding to wing attachment factors, is important for guaranteeing the security and reliability of plane operations.

Moreover, within the growth of high-performance sports activities automobiles, understanding embedding loss within the suspension elements can result in extra exact dealing with and improved efficiency.

Comparability of Embedding Loss in Completely different Functions

| Software | Particular Problem | Influence of Embedding Loss | Mitigation Methods |

|---|---|---|---|

| Aerospace | Sustaining structural integrity underneath excessive flight circumstances | Decreased fatigue life, potential for catastrophic failure | Optimized bolt design, improved materials choice, rigorous testing protocols |

| Automotive | Making certain engine mounting stability and longevity | Elevated vibration, lowered engine life, compromised car efficiency | Exact bolt tightening procedures, improved gasket supplies, and enhanced design of the mounting factors |

| Strain Vessels | Stopping leaks and guaranteeing structural integrity underneath excessive strain | Compromised stress distribution, potential for leaks or failure | Superior Finite Factor Evaluation (FEA) fashions that account for embedding loss, and use of superior supplies. |

Optimization Methods

Minimising embedding loss in bolted joints is essential for reaching strong and dependable mechanical assemblies. Efficient optimization methods embody materials choice, floor remedies, and meticulous preloading methods. These approaches are very important for guaranteeing structural integrity and efficiency throughout numerous engineering purposes.Optimizing bolted joint design to minimise embedding loss necessitates a multifaceted method. This includes not solely understanding the underlying ideas of fabric behaviour but additionally the sensible concerns of producing processes and meeting procedures.

Cautious consideration to element in every stage can result in vital reductions in embedding loss, translating to improved total system efficiency.

Materials Choice and Floor Therapies

Collection of superior supplies with superior mechanical properties and lowered tendency for deformation is paramount. As an example, high-strength alloys like superior steels exhibit greater yield strengths, resulting in lowered embedding loss in comparison with standard supplies. Floor remedies like shot peening can improve floor hardness and compressive residual stresses, additional minimizing deformation and thus embedding loss. These remedies additionally contribute to fatigue resistance, growing the longevity of the bolted joint.

Preloading and Tightening Methods

Optimum preloading and tightening procedures are crucial for minimizing embedding loss. Exact management over the utilized preload ensures a constant clamping drive throughout the joint, stopping localized deformation. Using calibrated torque wrenches and managed tightening sequences are important for correct preload software. Superior methods, corresponding to these incorporating suggestions mechanisms, additional optimize the tightening course of, decreasing the danger of over-tightening or under-tightening, each of which might negatively affect the ultimate consequence.

Optimization Methods and Influence on Embedding Loss

| Optimization Method | Potential Influence on Embedding Loss | Instance Software |

|---|---|---|

| Excessive-strength metal bolts with improved floor end | Decreased deformation, improved load switch | Plane fuselage meeting, high-pressure vessels |

| Shot peening of bolt threads and mating surfaces | Elevated floor hardness, enhanced compressive residual stresses | Heavy equipment elements, strain vessel joints |

| Exact preloading utilizing calibrated torque wrenches | Uniform clamping drive, minimized localized deformation | Automotive engine block assemblies, structural connections |

| Managed tightening sequences with suggestions mechanisms | Optimum preload software, minimized danger of over/under-tightening | Excessive-precision instrumentation, crucial structural parts |

| Optimized fastener choice (e.g., contemplating thread geometry and materials properties) | Decreased stress concentrations, improved load distribution | Bridges, constructing constructions |

Future Tendencies and Analysis Instructions

A deeper understanding of embedding loss in bolted joints is essential for optimising structural integrity and reliability. Future analysis ought to transfer past present methodologies to discover rising applied sciences and supplies, resulting in extra strong and environment friendly designs. This necessitates an exploration of novel analytical and experimental approaches to quantify embedding loss with better accuracy and precision.

Rising Analysis Areas, Learn how to calculate embedding loss in bolted joint

Present analysis predominantly focuses on empirical estimations of embedding loss. Future analysis ought to discover superior computational modelling methods, integrating finite factor evaluation (FEA) with machine studying algorithms. It will enable for extra correct predictions of embedding loss underneath complicated loading circumstances, together with fatigue and cyclic loading, and enhance the understanding of fabric behaviour in bolted connections.

Potential Future Developments in Analytical Methods

Integrating superior FEA with machine studying algorithms is essential. This will mannequin complicated stress distributions inside the joint with better precision. Creating novel constitutive fashions for supplies underneath excessive stress and deformation can be necessary. Moreover, using superior non-destructive analysis (NDE) methods for real-time monitoring of embedding loss throughout operation is a key space for future analysis.

This could facilitate real-world purposes and improve predictive upkeep methods.

Potential Future Developments in Experimental Methods

The event of superior experimental setups, able to replicating real-world loading circumstances and environments, is crucial. Utilizing superior microscopy methods for detailed evaluation of the embedded fastener and surrounding materials will present priceless insights. Moreover, using superior sensor expertise to measure native stress and pressure throughout loading, will supply invaluable insights into the mechanisms of embedding loss. It will enable for a deeper understanding of the connection between materials properties and embedding loss.

Influence of New Supplies and Applied sciences

Using superior supplies, corresponding to high-strength steels, composites, and superior polymers, will necessitate new fashions and approaches to quantify embedding loss. Furthermore, the rise of additive manufacturing (3D printing) for creating complicated geometries would require the event of latest analytical strategies to evaluate the integrity of bolted joints in these configurations. This presents a possibility to tailor the fabric properties to mitigate embedding loss and optimise joint efficiency.

Moreover, the exploration of sensible supplies with embedded sensors may allow real-time monitoring of embedding loss, resulting in proactive upkeep and improved reliability.

Want for Additional Analysis in Bolted Joint Design and Evaluation

The necessity for a complete framework for designing and analysing bolted joints is paramount. This framework should account for the variability in materials properties, loading circumstances, and manufacturing tolerances. Improvement of design tips incorporating practical estimations of embedding loss is crucial for guaranteeing the structural integrity and longevity of bolted connections. Moreover, additional analysis is required to know the affect of floor remedies, corresponding to coatings and floor roughness, on embedding loss in varied materials combos.

Final Phrase

In conclusion, calculating embedding loss in bolted joints requires a multi-faceted method encompassing analytical strategies, finite factor evaluation, experimental validation, and optimization methods. This information has offered a strong framework for tackling this crucial engineering problem. By understanding the elements influencing embedding loss, engineers can design extra dependable and environment friendly bolted joints, optimizing efficiency and longevity throughout varied purposes.

Clarifying Questions

What are the frequent varieties of bolted joints inclined to embedding loss?

By-bolted and blind-bolted joints are examples, with through-bolted joints typically exhibiting greater susceptibility as a result of better potential for deformation. The particular susceptibility is dependent upon elements like joint geometry and materials properties.

How does preload have an effect on embedding loss?

Preload considerably influences embedding loss. Larger preload usually ends in lowered embedding loss, because it helps distribute stress extra successfully throughout the joint. Nevertheless, extreme preload can result in different points, highlighting the necessity for cautious optimization.

What position does friction play in embedding loss?

Friction between the joint elements performs an important position. Excessive friction can cut back embedding loss, however extreme friction can result in localized stress concentrations, probably impacting the joint’s total integrity. Correct materials choice and floor remedy can affect friction and consequently embedding loss.

What are the everyday experimental setups used to measure embedding loss?

Experimental setups range, however they usually contain making use of managed hundreds and measuring deformation. Pressure gauges, displacement sensors, and cargo cells are generally used to acquire correct information. The particular setup is dependent upon the joint sort and the facet of embedding loss being investigated.