Tips on how to repair a ac tuen handel valve – Tips on how to repair a AC return/provide valve is an important talent for anybody sustaining their air-con system. Malfunctioning valves can result in important points, from decreased cooling effectivity to finish system failure. This information will stroll you thru the method of figuring out the issue, gathering the required instruments, disassembling the valve, inspecting elements, changing components (if wanted), reassembling, and eventually testing the system.

Understanding these steps can assist you tackle these issues successfully and keep away from pricey repairs.

This complete information will cowl all the course of from preliminary troubleshooting to ultimate system verification, making certain you perceive every step and are in a position to successfully deal with any points that come up. We’ll discover numerous valve varieties, frequent issues, and the troubleshooting procedures crucial for a profitable restore.

Figuring out the Difficulty

Proper, so AC return/provide valves, these aren’t precisely rocket science, however they may give you a proper headache in the event that they go pear-shaped. Understanding the frequent issues and signs is vital to getting your AC system again on observe. Mainly, these valves management the movement of air, and if they don’t seem to be working correctly, your complete system suffers.AC return/provide valves are important elements in any air-con system, regulating the airflow of cool air into your house and the elimination of heat air.

Malfunctions can result in uneven temperature distribution, decreased cooling effectivity, and probably, costly repairs down the road.

Frequent Issues with AC Valves

AC return/provide valves, like all mechanical element, can expertise numerous points. Leaks within the valve seals are a typical drawback, resulting in airflow points and a lack of refrigerant. Clogged filters or particles build-up within the valve can limit airflow, lowering effectivity and probably inflicting the valve to malfunction. Corrosion and rust are additionally potential issues, particularly in older programs, resulting in restricted airflow and valve harm.

Incorrect set up or improper upkeep practices can even contribute to those issues.

Signs of a Malfunctioning AC Valve

Recognising the signs of a defective AC valve is essential for immediate prognosis and restore. Noticeable signs embody uneven room temperatures, a major drop in cooling efficiency, unusual noises coming from the AC unit, or a noticeable lack of airflow in sure rooms. You may additionally see condensation pooling across the AC unit, which might point out a leak or stress challenge.

In the event you’re getting all these signs, it is time to examine the valve.

Sorts of AC Return/Provide Valves and Potential Failure Factors

Several types of valves exist, every with its personal potential failure factors. Ball valves are easy, however their seals can put on down over time, inflicting leaks and proscribing airflow. Butterfly valves, whereas environment friendly, can undergo from sticking or binding points, stopping correct airflow regulation. Diaphragm valves provide a better stage of precision however are extra prone to wreck from stress fluctuations.

Comparative Evaluation of AC Valve Varieties

| Valve Sort | Frequent Issues | Troubleshooting Steps | Attainable Options |

|---|---|---|---|

| Ball Valve | Leaking seals, sticking ball, particles build-up | Examine seals for put on, verify for obstructions, confirm correct lubrication | Change seals, clear valve, lubricate if crucial |

| Butterfly Valve | Sticking, binding, broken actuator, leaks in shaft seals | Examine for binding, verify actuator operation, confirm seal integrity | Lubricate actuator, change actuator, change shaft seals |

Gathering Instruments and Supplies: How To Repair A Ac Tuen Handel Valve

Proper, so you’ve got nailed figuring out the issue with that AC return/provide valve. Now, let’s get all the way down to the nitty-gritty of the instruments and components wanted for the repair. This part lays out the whole lot you may want, from primary hand instruments to probably specialised HVAC gear. Crucially, it additionally covers security precautions – important for any work involving compressed air and electrical elements.Understanding the precise restore wanted is vital.

Completely different points name for various instruments and substitute components. A easy valve deal with substitute is a special kettle of fish in contrast to an entire valve overhaul. The desk beneath particulars potential eventualities and the required gear.

Required Instruments and Elements

That is the lowdown on the instruments and substitute components required for various AC valve restore eventualities. Realizing which instruments you want will prevent a load of trouble and time.

| Restore State of affairs | Required Instruments | Alternative Elements |

|---|---|---|

| Valve Seal Alternative | Adjustable wrench, crescent wrench, needle-nose pliers, pipe wrench (if crucial), flathead screwdriver, valve seal substitute package (containing new seals, probably gaskets), cleansing rags/wipes. | New valve seal(s), presumably gaskets. |

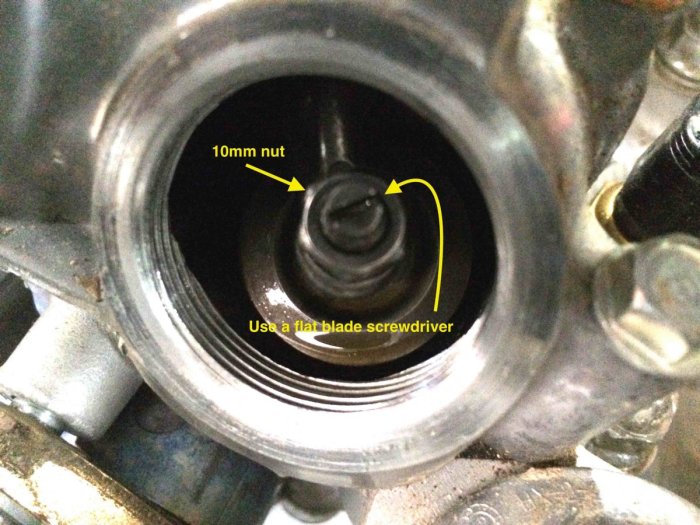

| Valve Deal with Alternative | Screwdriver (Phillips or flathead, relying on the valve), adjustable wrench, pliers, substitute valve deal with. | New valve deal with, probably retaining screws/washers. |

| Full Valve Alternative | Adjustable wrench, crescent wrench, pipe wrench (if crucial), socket set (for numerous bolt sizes), torque wrench (extremely beneficial), new valve. | New AC return/provide valve. |

Security Precautions

Working with AC programs entails potential hazards. At all times prioritise security. Earlier than beginning any restore, make sure the AC unit is powered down and the system is depressurised. That is paramount to stop damage from compressed gasoline or electrical shock. In the event you’re not completely assured with the procedures, seek the advice of a professional HVAC technician.

Do not be a hero – security first.

Disassembling the Valve

Proper, so you’ve got bought the AC return/provide valve wanting a bit dodgy. Time to get your palms soiled and get it sorted. This part covers the secure and systematic dismantling course of. Bear in mind, security first! Incorrect procedures can result in severe points, so observe these steps meticulously.

Protected Disconnection of the AC Return/Provide Valve

Earlier than touching something, make sure the system is powered down. This prevents electrical shocks and potential harm to elements. Find the ability provide connection for the AC unit and punctiliously disconnect it. Mark the reference to a label or take a photograph to make sure correct reconnection. Afterward, isolate the valve from the remainder of the system by closing any valves within the line to stop refrigerant leaks.

Eradicating the Valve from its Housing

This half requires cautious dealing with to keep away from damaging the valve or its housing. First, establish any securing mechanisms, similar to screws, clamps, or clips. Use the suitable instruments (screwdrivers, pliers, and so forth.) to loosen and take away these fasteners. Pay shut consideration to the orientation and place of the elements. Take pictures or make notes as you go.

This can assist in reassembly. As soon as all fasteners are eliminated, gently pull the valve out of its housing, taking care to not harm the connections or seals.

Disassembly Steps

This part Artikels the systematic steps for disassembling the valve, emphasising essential factors. Improper disassembly can result in harm and necessitate pricey replacements.

- Step 1: Disconnect Energy and Safe the Space. Guarantee the ability to the AC unit is totally disconnected. Mark the connections for simple reassembly. Safe the world to stop any unintentional motion or disturbance. This precaution prevents accidents and harm to elements.

- Step 2: Isolate the Valve from the System. Shut any valves within the refrigerant traces that hook up with the valve. This isolates the valve from the remainder of the system, stopping refrigerant leaks. Utilizing a valve key’s important for this job. Failure to isolate the valve may end up in a launch of refrigerants, which may harm the atmosphere.

- Step 3: Take away Securing Fasteners. Fastidiously take away any fasteners securing the valve to its housing. Use the suitable instruments, similar to screwdrivers or pliers. Document the place and orientation of every element to help in reassembly. Incorrectly eradicating these fasteners may end up in harm to the housing or the valve.

- Step 4: Gently Extract the Valve. Fastidiously take away the valve from its housing. Use warning to keep away from damaging the valve or its connections. Take your time and be exact. Injury to the valve or its connections might result in inefficient operation of the AC unit.

- Step 5: Examine and Doc. Study all elements for indicators of injury or put on. Take pictures or make notes of any noticed points or uncommon markings. Thorough inspection ensures a correct understanding of the valve’s present state.

Disassembly Process Desk

| Step | Motion | Picture Description |

|---|---|---|

| 1 | Disconnect energy to the AC unit utilizing the proper instruments. Guarantee all connections are correctly labeled and marked for simple reassembly. | A picture displaying the ability wire disconnected from the AC unit. The connections are clearly labeled and marked. |

| 2 | Shut the valves within the refrigerant traces related to the valve. This isolates the valve from the remainder of the system, stopping refrigerant leaks. | A picture of the valves within the refrigerant traces being closed. The valve key’s seen. |

| 3 | Fastidiously take away any securing fasteners. Notice the orientation of every element. | A picture showcasing the elimination of screws or clips securing the valve to the housing. Instruments are appropriately positioned and used. |

| 4 | Gently pull the valve from its housing, taking care to not harm the connections. | A picture depicting the valve being extracted from its housing. The valve is being rigorously pulled out. |

| 5 | Examine all elements for harm and doc any points. | A picture displaying a close-up inspection of the valve and its elements. The inspector is checking for harm or put on. |

Inspecting and Diagnosing the Downside

Proper, so you’ve got bought the valve disassembled, now it is time to suss out the problem. This stage is essential; a correct prognosis prevents you from changing components unnecessarily. An intensive inspection will pinpoint the precise drawback, saving you money and time.

Visible Inspection of Elements

A scientific visible verify is vital. Fastidiously study every half for indicators of injury. Search for cracks, chips, or any deformation within the steel elements. Examine the seals for put on and tear; any indicators of serious put on, like grooves or splitting, ought to be famous. Take note of the situation of the deal with and any connections.

Even a small hairline crack can result in a significant challenge.

Frequent Points Throughout Inspection

Figuring out potential issues early on saves numerous trouble later. This is a listing of frequent points that may be recognized throughout a visible inspection:

- Cracked or fractured valve physique.

- Worn or broken seals (O-rings, gaskets). These are sometimes the perpetrator behind leaks.

- Bent or damaged valve stem or deal with.

- Corrosion on steel components, which may weaken them.

- Free or broken connections.

- Obstructions or particles lodged inside the valve.

An intensive verify is necessary to know the potential drawback, not simply discovering one symptom.

Diagnosing the Root Trigger

Simply discovering harm is not sufficient; we have to understandwhy* the valve is not working. This entails testing and comparability. Think about the operational historical past of the valve. Has it been used closely just lately? Has there been a change within the fluid getting used?

- Leak testing: A leak take a look at helps pinpoint the precise location of a leak. Use soapy water to establish air bubbles, which point out leakage factors. Notice the precise location of leaks, as this can assist diagnose the issue.

- Strain testing: This methodology can establish structural points, similar to cracks or weakened components. A stress gauge and a secure stress stage are crucial.

- Comparability with diagrams: Referencing producer diagrams is important. This ensures you are analyzing the precise components and checking for normal dimensions.

- Figuring out the kind of fluid: Completely different fluids have totally different results on seals and elements. Realizing the kind of fluid used within the system is necessary.

Figuring out Particular Issues with Elements, Tips on how to repair a ac tuen handel valve

Pinpointing the precise half inflicting the problem is important.

- Worn Seals: Examine the seals for indicators of damage. If the seals are worn, they’re going to possible be leaking. A visible inspection can verify this.

- Broken Handles: Study the valve deal with for any cracks, bends, or unfastened connections. A broken deal with could also be a symptom of a extra important underlying challenge or just point out a weak level that might be a future drawback.

That is essential; the precise prognosis is step one in direction of a swift and environment friendly restore.

Changing Elements (if wanted)

Proper, so you’ve got identified the issue, now it is time to get your palms soiled and swap out any defective elements. This part will information you thru the method of changing worn-out or broken components, making certain a correct set up and reassembly. Correct half substitute is essential for the valve’s longevity and environment friendly operation.Changing components entails cautious consideration to element, making certain that every element is put in appropriately to keep away from leaks and make sure the valve capabilities as meant.

An intensive understanding of the precise valve’s design is important to keep away from making errors through the substitute course of.

Changing Valve Seals

The valve seal is a important element, usually the perpetrator behind leaks. A worn or broken seal can result in poor efficiency and potential harm. To exchange it, you want the proper substitute seal.

- Make sure the outdated seal is totally eliminated, cleansing the sealing floor completely to take away any particles or residue. That is important for a correct seal.

- Place the brand new seal onto the valve housing, making certain it aligns appropriately with the present grooves. A correctly positioned seal is important for the valve to work appropriately.

- Apply a skinny layer of applicable lubricant to the seal’s perimeter, facilitating clean operation and stopping friction. Correct lubrication is vital for the seal to operate appropriately.

Changing the Actuator (if relevant)

If the actuator is defective, you may want to interchange it. Actuators management the valve’s motion, so a malfunctioning one may end up in poor management and potential harm.

- Fastidiously disconnect the actuator from the valve, making certain that every one electrical connections are correctly remoted and disconnected.

- Place the brand new actuator into the valve housing, making certain it aligns appropriately with the present mounting factors. Misalignment can result in points with the actuator’s operation.

- Reconnect the actuator to the valve, making certain that every one electrical connections are securely reconnected and that the actuator is correctly seated. Confirm that the connections are appropriate to keep away from electrical issues.

Reassembling the Valve

Following the correct reassembly sequence is essential to stop points with the valve’s operation. Incorrect reassembly can result in leaks or malfunctions.

- Place the valve physique and canopy onto the valve housing, making certain they’re correctly aligned and secured.

- Tighten the mounting screws, making certain even stress is utilized and that the elements are firmly connected.

- Examine for any leaks across the joints utilizing a leak detection resolution. That is important for making certain the valve capabilities appropriately.

Compatibility Desk

| Half Title | Description | Compatibility |

|---|---|---|

| Valve Seal | A rubber or artificial o-ring or gasket that creates a seal between elements. | Guarantee the scale of the brand new seal match the outdated seal to ensure a correct match. Examine the producer’s specs for precise compatibility particulars. |

| Actuator | The element that strikes the valve. | Compatibility depends upon the valve’s particular mannequin and specs. Seek the advice of the producer’s half checklist or the valve’s documentation. |

| Mounting Screws | Securing elements to the valve physique. | Guarantee the proper measurement and sort of screws are used, as improper use can result in harm. Discuss with the producer’s specs. |

Reassembling the Valve

Proper, so you’ve got wrestled with the valve, recognized the problem, and changed any dodgy bits. Now, it is time to put all of it again collectively like a professional. Bear in mind, precision is vital right here; a misaligned element might result in a complete heap of points down the road. Getting it spot on is paramount.

Reconnecting the AC Return/Provide Valve

To reconnect the valve, make sure the O-rings and seals are in good nick. A worn or broken seal will compromise the airtightness of the system, probably inflicting leaks and decreased effectivity. Examine every element for any seen harm or indicators of damage. If something appears questionable, change it instantly. That is essential for long-term efficiency.

Appropriately Aligning and Securing the Valve

Exact alignment of the valve housing is important. Incorrect alignment can result in leaks and uneven airflow. Use a dial gauge or comparable precision software to make sure the valve is centered and correctly seated within the housing. Tighten the securing bolts progressively, in a star sample, to stop distortion and guarantee even clamping stress throughout the valve physique.

Over-tightening could cause harm to the threads or the valve housing itself. It is all about discovering that candy spot between safe and secure.

Testing the Valve Submit-Reassembly

As soon as the valve is reassembled, it is time for an intensive take a look at. Start by checking for leaks across the valve housing and connections. Apply soapy water to all joints and search for bubbles. No bubbles means seal. Subsequent, activate the AC system and monitor the airflow.

Make sure the valve is regulating the movement as meant. Any uncommon noises or uneven airflow might point out an issue that wants additional consideration.

Reassembly Steps Abstract

| Step | Motion | Notes |

|---|---|---|

| 1 | Align valve housing with the return/provide line utilizing a dial gauge to make sure exact centering. | Make sure the valve is correctly aligned to stop leaks and uneven airflow. |

| 2 | Fastidiously reinsert the O-rings and seals into their respective positions. | Verify that O-rings and seals are in good situation. Change if broken. |

| 3 | Tighten the securing bolts in a star sample to keep away from distortion and guarantee even clamping stress. | Tighten bolts progressively, avoiding over-tightening. |

| 4 | Examine for leaks by making use of soapy water to all joints and connections. | No bubbles point out seal. |

| 5 | Activate the AC system and monitor airflow. | Make sure the valve regulates movement as meant. |

Testing and Verification

Proper, so you’ve got wrestled with the valve, now it is time to see in case your handiwork really works. Correct testing is essential to make sure a clean AC operation and keep away from additional complications down the road. This part will cowl the important steps for verifying your restore.

Testing the AC System

The AC system wants an intensive take a look at to substantiate the repaired valve’s effectiveness. First, swap the system on and monitor the refrigerant movement. Observe if the compressor cycles appropriately and the condenser fan operates as anticipated. This preliminary verify will shortly establish any obvious points.

Anticipated Performance of a Return/Provide Valve

A appropriately functioning AC return/provide valve will permit the refrigerant to movement easily between the evaporator and compressor. This ensures the system maintains the correct stress and temperature differentials. The valve’s response ought to be quick and constant, with no noticeable fluctuations. Any delays or inconsistent operation might level to a lingering challenge.

Verification Guidelines

This guidelines ensures all features of the restore are accounted for, like a correct QA verify.

- Compressor operation: Verify the compressor begins and runs persistently, indicating a steady refrigerant movement.

- Condenser fan operation: Make sure the condenser fan capabilities, which is important for correct warmth dissipation and environment friendly system cooling.

- Refrigerant stage: Confirm the refrigerant stage is inside the optimum vary. Low refrigerant ranges will have an effect on the AC’s efficiency. Think about using a gauge for precision.

- Strain readings: Take stress readings at key factors within the system, evaluating them to producer specs. Deviations from the anticipated values can point out a leak or improper valve operate.

- Temperature differentials: Observe the temperature distinction between the evaporator and condenser. A big distinction signifies that the refrigerant is flowing as anticipated.

- System response: Assess the AC’s response to altering environmental situations, making certain a speedy and efficient cooling impact.

Monitoring the AC System Submit-Restore

Monitoring the AC system post-repair is important for early detection of any rising issues. Proactive monitoring permits for well timed intervention earlier than the problem escalates.

- Common checks: Schedule common checks on the AC system to observe stress, temperature, and different key parameters. A weekly or bi-weekly verify is an effective follow.

- System logs: Maintain a log of all readings and observations to trace any potential patterns or developments. This historic information will show helpful for troubleshooting.

- Leak detection: Implement a leak detection process to shortly establish any refrigerant leaks. A leak detection package is useful for this objective.

- Environmental components: Be aware of environmental components like ambient temperature. Excessive ambient temperatures can place elevated stress on the AC system.

- Addressing points: Tackle any noticed points promptly to stop additional issues and keep optimum AC efficiency.

Last Abstract

Efficiently repairing an AC return/provide valve requires a methodical strategy, from preliminary prognosis to ultimate system testing. By following the steps Artikeld on this information, you possibly can confidently tackle these points, making certain your AC system capabilities optimally. Bear in mind to prioritize security all through the method and seek the advice of professionals if wanted. This information offers a stable basis for dealing with these repairs successfully.

Clarifying Questions

What are the commonest causes of AC return/provide valve malfunction?

Frequent causes embody worn seals, broken handles, obstructions within the valve, and points with the valve’s inner elements. Typically, a malfunctioning valve is a symptom of a bigger drawback within the AC system, similar to a refrigerant leak.

What security precautions ought to I take when engaged on AC programs?

At all times disconnect the ability provide to the AC unit earlier than beginning any restore work. Use applicable private protecting gear (PPE), similar to gloves and security glasses. Be cautious of sharp edges and potential refrigerant leaks. If uncertain about any step, seek the advice of a professional HVAC technician.

How do I do know if a substitute half is appropriate with my valve?

Discuss with the producer’s specs or diagrams for the proper half numbers and dimensions. Compatibility charts and diagrams ought to be out there with substitute components or from the producer’s web site.

What are the indicators of a leak within the AC system?

Uncommon noises, decreased cooling capability, seen liquid across the AC unit, or a noticeable drop in refrigerant ranges can all point out a leak. At all times be cautious of refrigerant as it may be dangerous.