Tips on how to set up a stopper in hazmat cupboard? This information gives an in depth, step-by-step strategy to make sure correct set up, emphasizing security and compliance. From understanding the completely different stopper varieties to mastering the set up course of, this useful resource will equip you with the data and confidence to deal with this vital activity accurately. Correct stopper set up is paramount for security in hazmat environments, stopping spills and accidents.

Choosing the proper stopper in your hazmat cupboard is important. This information will Artikel the varied varieties, their strengths and weaknesses, and the elements to contemplate when choosing the suitable one in your particular cupboard mannequin. We’ll additionally delve into the essential security measures that should be noticed all through the set up course of. Security first!

Introduction to Hazmat Cupboard Stoppers

Hazmat cupboard stoppers are essential elements in sustaining the integrity and security of those specialised storage items. They function a significant barrier in opposition to unauthorized entry, stopping unintended spills or exposures to hazardous supplies. Their perform extends past easy closure, taking part in a vital position in guaranteeing compliance with security laws and defending personnel. The choice of applicable stoppers is paramount, impacting not solely security but additionally the environment friendly operation of the cupboard itself.The performance of hazmat cupboard stoppers is intrinsically linked to the kind of hazardous materials being saved.

Totally different stoppers are designed for varied cupboard configurations and materials varieties, emphasizing the necessity for cautious consideration throughout choice. The various varieties out there, every with distinctive traits, decide the general effectiveness and safety of the storage system. This necessitates an intensive understanding of the completely different stopper varieties to ensure optimum security and adherence to regulatory requirements.

Forms of Hazmat Cupboard Stoppers

Stoppers for hazmat cupboards are categorized based mostly on their mechanism of closure. This range displays the precise necessities of varied storage functions. Correct choice is essential for guaranteeing each security and regulatory compliance.

Comparability of Stopper Sorts

Totally different stopper varieties current various benefits and downsides. Cautious analysis of those elements is important for choosing essentially the most appropriate stopper for a specific software.

| Stopper Sort | Mechanism | Benefits | Disadvantages |

|---|---|---|---|

| Screw-on | Secured by a threaded mechanism | Comparatively cheap, available, and easy to put in. Robust sealing when correctly tightened. | Potential for over-tightening, main to wreck to the cupboard or stopper. Is probably not appropriate for all cupboard varieties. Will be susceptible to loosening over time. |

| Snap-in | Engaged by a locking mechanism | Quick and straightforward set up. Reduces the chance of over-tightening, minimizing injury to the cupboard. Normally sturdy and immune to put on and tear. | Could not supply the identical degree of sealing as screw-on stoppers. Not as versatile for various cupboard configurations. |

| Lever-operated | Secured by a lever mechanism | Simple to function, even with gloved palms. Good for frequent opening and shutting. Offers a safe seal when engaged accurately. | Will be prone to wreck if the lever mechanism isn’t dealt with with care. Set up may require extra precision than different varieties. |

| Mixture | Hybrid design incorporating a number of closure mechanisms | Gives a mix of benefits from different varieties, doubtlessly maximizing sealing and safety. Adaptable to a wider vary of cupboard types. | Extra complicated design, doubtlessly growing set up time and price. Requires cautious consideration of the precise elements’ strengths and weaknesses. |

Significance of Correct Stopper Choice

The proper alternative of stopper is paramount in stopping accidents and guaranteeing compliance. Failure to pick an applicable stopper may end up in extreme security hazards, together with unintended publicity to hazardous supplies, injury to the cupboard, and potential regulatory violations. The security and well-being of personnel are straight tied to the correct choice and set up of hazmat cupboard stoppers.

Security Issues for Set up

The set up of stoppers in a hazardous supplies (hazmat) cupboard calls for meticulous consideration to security protocols. Neglecting these precautions can result in severe penalties, starting from minor accidents to catastrophic incidents involving hazardous substances. Understanding and adhering to the protection procedures ensures a safe and managed surroundings for the set up course of.Correct set up of stoppers safeguards personnel and the encircling space from potential hazards.

Failure to comply with established security procedures can result in unintended publicity to hazardous supplies, gear malfunctions, or injury to the cupboard itself. Moreover, insufficient security measures throughout set up can compromise the integrity of the stopper system, resulting in untimely failure and doubtlessly compromising the containment of hazardous supplies.

Private Protecting Tools (PPE) Necessities

Making certain personnel security is paramount throughout stopper set up. Acceptable private protecting gear (PPE) is essential to mitigate the chance of publicity to hazardous supplies. The particular PPE necessities will fluctuate relying on the kind of hazardous supplies saved throughout the cupboard. Important PPE contains, however isn’t restricted to, chemical-resistant gloves, security glasses or goggles, a respirator (if relevant), and a protecting go well with.

These things are chosen based mostly on the precise hazards posed by the supplies current within the cupboard. The PPE needs to be inspected for injury or put on earlier than every set up.

Potential Hazards Related to Improper Set up

Improper set up of stoppers can introduce important hazards. Incorrect placement or tightening can result in leakage of hazardous supplies, creating a possible publicity threat. Insufficient sealing can enable for the entry of contaminants or the escape of pressurized gases, leading to harmful circumstances. Moreover, improperly put in stoppers can malfunction, growing the chance of spills and releases of hazardous substances.

Such incidents might doubtlessly trigger environmental injury and threaten the well being and security of people.

Secure Set up Process

Adherence to a structured set up process is important to make sure security. This process needs to be clearly Artikeld and communicated to all personnel concerned. A methodical strategy helps reduce errors and maximizes security. A complete step-by-step information ought to embrace the next:

- Pre-Set up Inspection: Completely examine the hazmat cupboard for any injury or indicators of decay. Examine the stopper itself for any defects or injury. Examine the storage circumstances of the hazardous supplies for any indicators of leakage or contamination. Correct situation of the cupboard and its contents ensures a protected set up course of.

- PPE Software: Guarantee all personnel concerned within the set up course of put on the required PPE. The particular PPE required is determined by the hazardous supplies current. Failure to put on applicable PPE may end up in severe accidents or diseases. This step prioritizes employee security and prevents publicity to hazardous supplies.

- Floor Preparation: Clear and dry the stopper set up floor to make sure correct adhesion and stop contamination. Thorough preparation of the set up floor helps obtain a safe seal and prevents the introduction of overseas supplies.

- Set up Process: Observe the producer’s directions for putting in the stopper. Adhering to the producer’s directions is essential for proper set up and optimum performance.

- Submit-Set up Checks: Conduct thorough checks to make sure the stopper is correctly put in and sealed. Examine the seal for any indicators of leakage or injury. This closing inspection confirms that the set up is full and the hazards have been addressed.

- Documentation: Report the date, time, and personnel concerned within the set up. Doc any deviations from the usual process. Correct documentation ensures accountability and facilitates future reference.

Step-by-Step Set up Procedures

The meticulous set up of a hazmat cupboard stopper is essential for sustaining the integrity and security of the enclosure. Improper set up can compromise the containment of hazardous supplies, resulting in potential environmental and well being dangers. Understanding the precise procedures for various stopper varieties and cupboard fashions is paramount for profitable implementation.The next sections delineate the exact steps required for putting in varied kinds of stoppers, offering a complete information for protected and efficient set up.

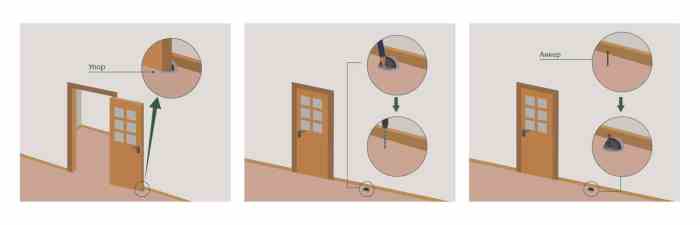

Screw-On Stopper Set up

The screw-on stopper set up course of includes securing the stopper to the cupboard’s designated mounting level utilizing a threaded mechanism. This technique gives a strong and safe connection, very best for environments requiring excessive ranges of containment.

- Step 1: Preparation. Completely examine the cupboard’s mounting space and the stopper for any injury or imperfections. Make sure the mounting floor is clear and freed from particles. The stopper ought to exhibit no indicators of harm or distortion.

- Step 2: Alignment. Rigorously align the stopper with the mounting holes on the cupboard. Confirm that the stopper’s mounting floor aligns completely with the cupboard’s mounting plate. Misalignment can result in improper sealing and potential leaks.

- Step 3: Safe the Stopper. Firmly hand-tighten the stopper’s mounting screws. Use a screwdriver to additional tighten the screws, guaranteeing even strain is utilized all through. Extreme tightening can injury the stopper or the cupboard, compromising its integrity.

- Step 4: Closing Inspection. Visually examine the stopper for any indicators of misalignment or free screws. Make sure the stopper is securely seated and the screws are firmly in place.

Snap-In Stopper Set up

The snap-in stopper set up technique leverages a easy locking mechanism, providing a faster and simpler set up course of. This design is usually favoured for its simplicity and pace of set up.

- Step 1: Positioning. Align the stopper with the cupboard’s designated mounting level. Make sure the stopper’s locking mechanism is positioned accurately.

- Step 2: Partaking the Lock. Gently press the stopper into the mounting space till it clicks into place. The press sound confirms that the stopper is securely engaged.

- Step 3: Verification. Visually verify that the stopper is totally seated and securely locked in place. A accurately put in stopper shouldn’t exhibit any wobble or looseness.

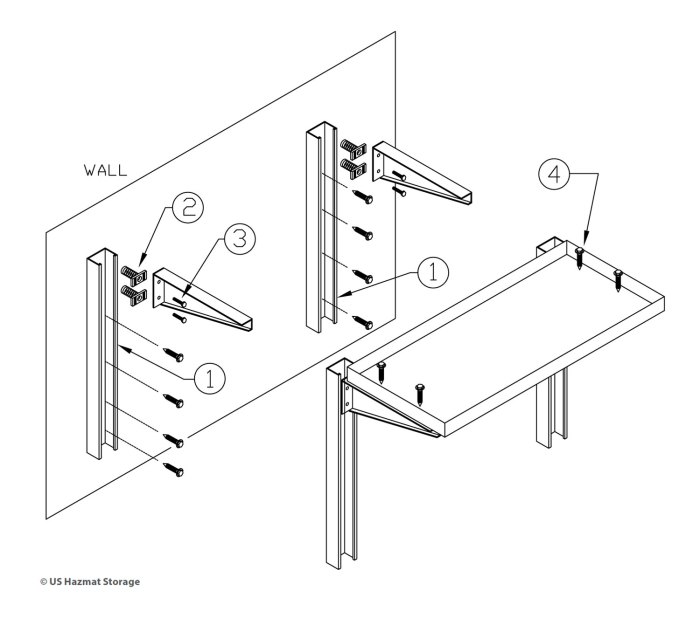

Stopper Set up on a Mannequin X Hazmat Cupboard

This instance particulars the set up of a screw-on stopper on a Mannequin X Hazmat Cupboard, that includes dimensions of 36 inches in width, 24 inches in depth, and 48 inches in top. The cupboard has a chosen mounting space with 4 mounting holes for the stopper.

| Step | Motion | Visible Description |

|---|---|---|

| 1 | Examine Mounting Space | Look at the cupboard’s mounting floor for any injury or particles. The floor needs to be clear and undamaged. |

| 2 | Align Stopper | Place the stopper over the cupboard’s mounting holes, guaranteeing exact alignment. The stopper needs to be flush with the cupboard’s face. |

| 3 | Tighten Screws | Hand-tighten the mounting screws till they’re comfortable. Use a screwdriver to additional tighten, making use of even strain. |

| 4 | Closing Examine | Confirm the stopper’s alignment and the tightness of the screws. The stopper needs to be securely mounted with none wobble. |

Instruments and Supplies Required

The profitable set up of a hazmat cupboard stopper hinges critically on the suitable choice and utilization of instruments and supplies. Careless or insufficient decisions can compromise the integrity of the stopper mechanism, doubtlessly jeopardizing the protection protocols of the cupboard itself. Moreover, a complete understanding of the precise necessities for every stopper sort is paramount to reaching a strong and safe set up.The meticulous preparation of instruments and supplies isn’t merely a technicality; it is a foundational facet of guaranteeing the long-term efficacy and security of the hazmat cupboard.

The proper instruments, coupled with the suitable supplies, will assure a safe and sturdy set up, contributing considerably to the cupboard’s general efficiency and security.

Important Instruments for Stopper Set up

A exact choice of instruments is essential for a protected and environment friendly set up. The selection of instruments straight influences the set up high quality and longevity of the stopper mechanism. The suitable instruments assure that the stopper is put in accurately and safely, avoiding potential hazards and injury to the cupboard.

- Wrenches: Numerous sizes and kinds of wrenches, together with adjustable wrenches, open-end wrenches, and socket wrenches, are important. The exact dimension of the wrench required is determined by the precise stopper’s mounting {hardware}. For instance, a 10mm wrench could be obligatory for a stopper with 10mm mounting bolts. Utilizing the wrong wrench dimension can injury the stopper or the cupboard’s {hardware}.

- Screwdrivers: Phillips and flathead screwdrivers are steadily required for securing the stopper’s elements. The suitable screwdriver sort is dictated by the kind of screws used within the stopper’s building. A stripped screw because of incorrect screwdriver sort will compromise the stopper’s set up and its general efficiency. The proper dimension and kind of screwdriver are important to keep away from damaging the screw head.

- Pliers: Needle-nose or slip-joint pliers are helpful for manipulating small elements, wires, or elements throughout set up. Their utility is important for duties like securing small elements or adjusting positioning parts of the stopper.

- Degree: A degree is important for guaranteeing the stopper is put in in a wonderfully horizontal place. This prevents uneven loading and potential points with the stopper’s sealing efficiency.

Stopper-Particular Software Issues

The kind of stopper considerably influences the required instruments. Totally different stopper designs necessitate particular instruments for optimum set up. Understanding the precise necessities of every stopper sort is vital for profitable set up.

- Mechanical Stoppers: These stoppers usually require specialised instruments, comparable to these with a singular locking mechanism or a selected tightening mechanism. Using the right instruments for mechanical stoppers ensures easy operation and prevents injury to the stopper’s elements.

- Magnetic Stoppers: Magnetic stoppers usually require a distinct set of instruments, which should account for the magnetic area generated by the stopper and the metallic elements. It will assure the integrity of the magnetic area and the protection of the cupboard.

- Mixture Stoppers: These stoppers might mix options of each mechanical and magnetic stoppers. The suitable toolset for mixture stoppers should tackle each the mechanical and magnetic elements of the stopper.

Supplies for a Safe Set up

The proper choice of supplies, comparable to lubricants and sealants, considerably influences the longevity and efficiency of the stopper. The suitable supplies assure the specified efficiency and security.

- Lubricant: An appropriate lubricant, comparable to white lithium grease, is essential for guaranteeing easy operation and stopping friction between transferring elements. This lubrication will stop untimely put on and tear on the stopper mechanism.

- Sealant: A high-quality sealant, comparable to a silicone-based sealant, is important for making a watertight seal between the stopper and the cupboard’s body. It will keep the structural integrity and stop the cupboard from leaking.

- Spare Elements: Holding a small equipment of spare elements readily available, comparable to screws, washers, or O-rings, is important for addressing any unexpected points in the course of the set up course of. It will scale back downtime and potential delays throughout set up.

Troubleshooting Frequent Points

Correct set up of hazmat cupboard stoppers is essential for sustaining security and stopping accidents. Understanding potential pitfalls and their resolutions empowers customers to deal with issues successfully, guaranteeing the integrity and performance of the containment system. This part delves into frequent set up issues, their underlying causes, and efficient options.Troubleshooting throughout stopper set up necessitates a scientific strategy, recognizing the potential for error at every stage.

A radical understanding of the precise cupboard mannequin and the stopper’s design traits is paramount to figuring out and resolving points swiftly and safely.

Figuring out Set up Issues

Precisely diagnosing set up issues is step one towards a profitable decision. Cautious remark of the stopper’s alignment, match, and general integration with the cupboard is important. Visible inspection, mixed with a methodical assessment of the set up procedures, aids in pinpointing the supply of any discrepancies. The character of the issue, whether or not it includes improper alignment, insufficient securing, or incompatibility with the cupboard’s design, dictates the suitable plan of action.

Causes of Set up Issues

A number of elements can contribute to difficulties throughout hazmat cupboard stopper set up. Insufficient preparation, misinterpretation of set up directions, or a scarcity of familiarity with the precise stopper mannequin can result in issues. Moreover, instruments not fitted to the duty or improper dealing with of elements may also hinder the set up course of. Compatibility points between the stopper and the cupboard’s particular design or unexpected structural discrepancies within the cupboard itself may also contribute to the issue.

Options to Resolve Set up Points

Addressing set up issues successfully requires a methodical strategy. Firstly, assessment the set up directions rigorously, guaranteeing a whole understanding of the steps concerned. Referencing diagrams and illustrations can show useful in deciphering any ambiguity. Secondly, double-check the compatibility of the stopper with the precise hazmat cupboard mannequin. Confirming the right stopper sort and guaranteeing all obligatory elements are current is essential.

If the difficulty persists, seek the advice of with a certified skilled for knowledgeable steering.

Troubleshooting Desk

| Potential Downside | Trigger | Answer |

|---|---|---|

| Stopper doesn’t match securely | Improper alignment, incorrect stopper mannequin, or broken cupboard elements. | Confirm correct alignment with the cupboard. Guarantee the right stopper mannequin is used. Examine the cupboard for any injury that would impede the stopper’s match. If obligatory, realign or restore the cupboard. |

| Stopper leaks | Improper set up, insufficient sealing, or injury to the stopper’s gasket. | Re-examine the set up course of for correct sealing. Make sure the gasket is unbroken and correctly seated. Change the stopper if injury is clear. |

| Stopper alignment points | Incorrect placement, mismatched elements, or uneven cupboard surfaces. | Confirm appropriate placement based mostly on the set up directions. Guarantee all elements are appropriate. If obligatory, modify the cupboard surfaces to make sure even help for the stopper. |

| Stopper is troublesome to put in | Incorrect instruments used, insufficient lubrication, or resistance from cupboard elements. | Use applicable instruments designed for the stopper set up. Apply a lubricant if essential to facilitate easy insertion. Rigorously examine the cupboard elements for any obstructions. |

Compliance and Rules

The set up of stoppers in hazardous supplies (hazmat) cupboards isn’t merely a matter of practicality; it is a essential facet of security and regulatory compliance. Failure to stick to established requirements can result in important repercussions, starting from fines and authorized motion to potential accidents and accidents. This part delves into the precise laws and requirements governing hazmat cupboard stopper set up, highlighting the significance of compliance and outlining key necessities throughout varied areas.

Related Rules and Requirements

Compliance with hazmat cupboard stopper set up hinges on adhering to a posh net of laws and requirements. These pointers are designed to make sure the protection of personnel and the surroundings, stopping potential hazards related to improper storage and dealing with of hazardous supplies. Key organizations chargeable for establishing these requirements usually embrace nationwide fireplace codes, security businesses, and native constructing codes.

These laws, although numerous of their phrasing and specifics, share a standard thread of prioritizing security and minimizing dangers.

Particular Compliance Necessities

Totally different areas and jurisdictions have their very own particular compliance necessities for hazmat cupboard stopper set up. These variations can stem from various ranges of threat evaluation, environmental issues, and native constructing codes. As an illustration, sure areas might mandate particular kinds of stoppers, set up strategies, or testing procedures. Understanding these variations is vital for guaranteeing full compliance.

Significance of Adherence to Rules

Adherence to hazmat cupboard stopper set up laws is paramount. This dedication to compliance not solely protects personnel working with hazardous supplies but additionally safeguards the broader group. Failure to conform can result in severe penalties, together with: fines, authorized motion, potential accidents, and environmental injury. The implications of non-compliance are substantial, thus making it important for all stakeholders concerned in hazmat cupboard administration to grasp and cling to the relevant laws.

Desk of Key Compliance Necessities

| Area/Jurisdiction | Key Compliance Necessities | Related Requirements |

|---|---|---|

| United States (e.g., OSHA, NFPA) | Particular stopper varieties for varied hazards, correct anchoring strategies, common inspections, and upkeep schedules. | NFPA 452, OSHA 29 CFR 1910, and native constructing codes. |

| European Union (e.g., REACH, CLP) | Compliance with particular hazard classifications, labeling necessities, and storage protocols. Stopper choice should align with the precise hazard class. | European Union Directives on chemical compounds and security. |

| Canada (e.g., WHMIS) | Adherence to Office Hazardous Supplies Data System (WHMIS) laws, guaranteeing correct labeling and hazard communication protocols are in place. | Canadian WHMIS laws. |

| Australia (e.g., AS/NZS requirements) | Strict adherence to Australian and New Zealand security requirements, emphasizing the significance of correct stopper choice for particular hazards and the surroundings. | AS/NZS requirements for hazardous supplies. |

Upkeep and Inspection

The diligent upkeep of hazmat cupboard stoppers is paramount to making sure operational security and compliance with laws. Neglecting preventative measures can result in a failure in containment, doubtlessly jeopardizing personnel and the surroundings. Correct inspection and upkeep procedures safeguard in opposition to unexpected hazards, minimizing dangers and sustaining the integrity of the cupboard’s containment system.Efficient upkeep methods prolong the lifespan of the stoppers, lowering the chance of expensive repairs or replacements.

Common checks not solely stop catastrophic failures but additionally facilitate well timed interventions, thereby mitigating potential environmental or well being dangers. A proactive strategy to upkeep is vital in preserving the structural integrity and operational effectivity of the hazmat cupboard system.

Upkeep Procedures for Stopper Parts

Routine upkeep of hazmat cupboard stoppers encompasses a spread of procedures designed to determine and tackle potential points earlier than they escalate. These procedures embrace visible inspections, practical checks, and cleansing protocols. Complete upkeep protocols needs to be standardized and documented, serving as an important reference for each personnel and regulatory our bodies.

- Visible Inspection: Completely look at the stopper for any seen indicators of harm, comparable to cracks, warping, or deformation. Assess the situation of the seals and gaskets, guaranteeing they’re intact and freed from any obstructions. Observe the general structural integrity of the stopper meeting, figuring out any anomalies or looseness. Deviations from the unique design needs to be famous and investigated.

- Practical Checks: Confirm the correct operation of the stopper mechanism by making an attempt to interact and disengage the stopper. Check the locking mechanism to substantiate its performance and guarantee it’s working securely. Consider the convenience of operation and guarantee it doesn’t current any uncommon resistance or obstacle. Notice any inconsistencies or delays within the stopper’s operation.

- Cleansing Protocols: Make use of applicable cleansing options and strategies to take away any collected particles or contaminants from the stopper and its surrounding elements. Cleansing needs to be carried out utilizing non-abrasive supplies and strategies to forestall injury to the stopper’s floor. Observe producer pointers for particular cleansing brokers and procedures.

Inspection Frequency and Needed Checks

The frequency of inspections is determined by the utilization and operational surroundings of the hazmat cupboard. For prime-usage cupboards in energetic environments, extra frequent inspections are beneficial. Common checks and upkeep mitigate the chance of untimely failure and guarantee compliance with security requirements. Complete documentation of inspection findings is essential for monitoring upkeep historical past and figuring out potential traits.

- Month-to-month Inspections: A complete visible inspection of the stopper, together with the seals, gaskets, and locking mechanisms, needs to be performed month-to-month. This contains testing the performance of the stopper’s locking mechanism and checking for any indicators of wear and tear or injury. Any observations needs to be documented within the cupboard’s logbook.

- Quarterly Inspections: Quarterly inspections ought to contain a extra thorough examination, together with disassembly and cleansing of the stopper’s elements. This step permits for a deeper evaluation of the stopper’s inner situation and ensures that any potential points are addressed promptly. Any anomalies or deviations needs to be addressed in response to established procedures.

- Annual Inspections: Annual inspections ought to embody a whole evaluation of the stopper system, together with its elements, performance, and compliance with related laws. These inspections are important for verifying the general security and integrity of the hazmat cupboard.

Figuring out Indicators of Put on or Injury

Figuring out indicators of wear and tear or injury on stoppers is essential for well timed intervention and to forestall potential hazards. Common visible inspections can reveal delicate indications of decay, requiring fast consideration. These indicators embrace cracks, warping, deformation, and any looseness within the stopper’s elements. Visible remark of the seals and gaskets can reveal degradation or leakage, which also needs to be famous.

- Cracks and Warping: Any cracks, warping, or deformation within the stopper materials point out potential structural weak spot. These circumstances compromise the stopper’s potential to successfully comprise hazardous supplies.

- Seal and Gasket Degradation: Deterioration of seals and gaskets might result in leakage or insufficient containment. This situation warrants fast substitute and an intensive assessment of the set up course of.

- Looseness in Parts: Looseness in any a part of the stopper mechanism suggests potential instability. This will result in failure and compromise the containment system.

Greatest Practices for Preventative Upkeep

Implementing preventative upkeep methods can considerably scale back the chance of stopper failures. Proactive upkeep minimizes the chance of surprising incidents and ensures continued compliance with security requirements. Establishing a transparent schedule and protocol for routine checks, coupled with diligent documentation of findings, is essential for efficient preventative upkeep.

- Common Cleansing: Common cleansing prevents the buildup of particles and contaminants, which may speed up put on and tear on the stopper elements.

- Correct Storage: Storing the stoppers in a managed surroundings, away from excessive temperatures and corrosive supplies, protects their integrity and prolongs their lifespan.

- Adherence to Producer Pointers: Following the producer’s suggestions for cleansing, inspection, and upkeep procedures ensures the optimum efficiency and longevity of the stopper system.

Visible Aids for Understanding: How To Set up A Stopper In Hazmat Cupboard

A complete understanding of hazmat cupboard stoppers necessitates visible aids. These aids, starting from detailed diagrams to illustrative examples, facilitate comprehension of stopper varieties, their elements, and set up procedures. This part gives an in depth breakdown of screw-on and snap-in stoppers, together with examples of various hazmat cupboard fashions and their corresponding stopper necessities, all designed to reinforce sensible software.

Screw-on Stopper Parts, Tips on how to set up a stopper in hazmat cupboard

Screw-on stoppers are a standard sort utilized in varied hazmat cupboards. Understanding their elements is essential for correct set up and upkeep. These stoppers sometimes include a threaded base, a gasket for sealing, and a cap or cowl. The threaded base permits for safe attachment to the cupboard opening. The gasket, usually made from a resilient materials like neoprene or EPDM, creates a safe seal in opposition to the cupboard opening to forestall leakage.

The cap gives a completed aesthetic and ensures the stopper stays in place.

Snap-in Stopper Anatomy

Snap-in stoppers are one other prevalent sort, identified for his or her fast and straightforward set up. Their distinctive design incorporates a base with a locking mechanism, facilitating a safe match throughout the cupboard opening. The locking mechanism ensures that the stopper is securely mounted, stopping unintended elimination.

Hazmat Cupboard Mannequin Variations

Hazmat cupboards are available quite a lot of designs, and the stopper necessities can fluctuate. Understanding the precise mannequin is important for choosing the right stopper. As an illustration, upright cupboards might require completely different stopper designs in comparison with horizontal fashions because of variations within the cupboard opening and structural parts. A cupboard with a wider opening might necessitate a bigger stopper to make sure correct protection.

Diagrammatic Representations of Stopper Sorts

A sequence of diagrams illustrating completely different stopper varieties is significant. These diagrams will show the screw-on stopper with its threaded base, gasket, and cap elements. Moreover, the diagrams will clearly present the snap-in stopper with its base and locking mechanism. The illustrations may even depict the set up procedures, showcasing the correct alignment and placement of the stopper throughout the cupboard opening.

For instance, a diagram illustrating a screw-on stopper would come with labeled elements and point out the correct tightening torque. A diagram showcasing a snap-in stopper would illustrate the locking mechanism and its engagement with the cupboard.

Diagram Examples:

| Stopper Sort | Diagram Description |

|---|---|

| Screw-on Stopper | An in depth diagram of a screw-on stopper, highlighting the threaded base, gasket, and cap. Arrows point out the right tightening course and the correct placement of the gasket. |

| Snap-in Stopper | A diagram of a snap-in stopper, illustrating the bottom and the locking mechanism. The diagram will present the completely different elements participating with the cupboard opening, and the pressure required to safe the stopper. |

Closing Abstract

In conclusion, this complete information gives an in depth roadmap for putting in stoppers in hazmat cupboards. We have explored the completely different stopper varieties, security issues, step-by-step procedures, obligatory instruments, troubleshooting suggestions, compliance necessities, and essential upkeep practices. By following this information, you’ll be able to guarantee your hazmat cupboard is correctly outfitted and working safely, upholding the best requirements of security and compliance.

FAQ Part

What are the commonest causes for stopper failure?

Improper set up, utilizing the improper stopper sort for the cupboard, lack of upkeep, and injury from impression or put on are frequent causes for stopper failure. Understanding these potential points is vital to preventative upkeep.

What sort of lubricant ought to I exploit throughout set up?

Seek the advice of the stopper producer’s directions for particular suggestions. Some stoppers might not require any lubricant, whereas others may profit from a light-weight software of a appropriate lubricant. All the time prioritize security and select a lubricant that will not compromise the stopper’s seal or the cupboard’s integrity.

What are the standard dimensions of a screw-on stopper?

Screw-on stopper dimensions fluctuate relying on the hazmat cupboard mannequin. Seek advice from the hazmat cupboard’s technical specs and the stopper producer’s directions for exact dimensions.

How usually ought to I examine the stoppers?

The frequency of inspections is determined by the utilization and environmental circumstances. Seek the advice of the producer’s pointers or related security laws for beneficial inspection schedules.