learn AC gauges R134a is essential for any HVAC technician. Understanding these gauges is important for diagnosing and fixing AC system issues, from easy leaks to advanced malfunctions. This information dives deep into the world of AC gauge readings, offering a transparent and concise strategy to mastering this important talent.

This complete information will take you thru the fundamentals of AC gauge setups, explaining the various kinds of gauges and their features. We’ll discover the particular stress ranges for R134a in numerous system situations, and the best way to interpret stress readings precisely. The information additionally covers widespread AC system points and their corresponding gauge readings, enabling you to troubleshoot issues successfully.

Introduction to AC Gauges and R134a Refrigerant

Air-con (AC) programs depend on exact measurements and the right refrigerant to operate optimally. Understanding how AC gauges work and the traits of the refrigerant, like R134a, is essential for correct upkeep and environment friendly operation. Incorrect readings or improper refrigerant dealing with can result in system failure and dear repairs. This part delves into the basics of AC gauges and R134a, emphasizing the significance of correct measurements for efficient AC system prognosis.

Perform of AC Gauges

AC gauges are important instruments for monitoring the stress and circulation of refrigerant inside an AC system. These gauges present important details about the system’s working situations, enabling technicians to establish potential points and make knowledgeable choices for restore or upkeep. Completely different gauges measure completely different features of the system’s state. A manifold gauge set, as an illustration, sometimes contains two gauges, one for high-side stress and one other for low-side stress, essential for diagnosing leaks, refrigerant cost ranges, and different points.

Correct gauge readings are a key indicator of a system’s well being.

Properties and Traits of R134a Refrigerant

R134a is a generally used refrigerant in trendy AC programs. It possesses particular properties that affect its efficiency and security within the system. R134a is a colorless, odorless, and non-toxic fuel at regular temperatures and pressures. Its low world warming potential (GWP) in comparison with some older refrigerants makes it a extra environmentally pleasant selection. Understanding R134a’s thermodynamic properties, together with its boiling and condensing factors at completely different pressures, is significant for correct system prognosis.

Significance of Understanding R134a for Correct AC System Upkeep

Appropriately figuring out and addressing refrigerant points is important for sustaining an AC system’s effectivity and longevity. R134a, because of its particular properties, requires specific dealing with and upkeep. As an illustration, leaks within the system can result in a drop within the refrigerant cost, impacting the cooling capability and effectivity of the AC system. Understanding the properties of R134a permits technicians to find out the correct quantity of refrigerant wanted to take care of the specified cooling capability.

Significance of Correct Gauge Readings for AC System Analysis

Correct gauge readings are paramount for diagnosing and resolving AC system issues. By observing the stress readings on the excessive and low sides of the AC system, technicians can shortly establish issues like leaks, improper refrigerant cost, or points with the compressor or condenser. For instance, a constantly low high-side stress might point out a leak, whereas a excessive low-side stress may counsel a blockage.

Exact readings present the inspiration for correct troubleshooting and environment friendly repairs.

Comparability of R134a to Different Refrigerants

| Property | R134a | R22 (Older Refrigerant) | Ammonia (NH3) |

|---|---|---|---|

| International Warming Potential (GWP) | 1,430 | 1,810 | 0 |

| Toxicity | Non-toxic | Non-toxic | Poisonous |

| Ozone Depletion Potential (ODP) | 0 | 0.05 | 0 |

| Flammability | Non-flammable | Non-flammable | Flammable |

This desk supplies a concise comparability of R134a to different refrigerants, highlighting variations in environmental influence, security, and different traits. Understanding these distinctions is essential for making knowledgeable choices about refrigerant choice and upkeep procedures.

Understanding the AC Gauge Setups

Figuring out the best way to interpret AC gauge readings is essential for correct and environment friendly air con system upkeep and restore. Correct gauge use helps diagnose points shortly, minimizing downtime and restore prices. This part particulars various kinds of gauges, their features, typical stress ranges, and the best way to join them to your system.

Forms of AC Gauges

Varied varieties of gauges are used for AC programs, every with particular benefits. Manifold gauges are generally used for his or her dual-port design, permitting simultaneous measurement of excessive and low-side pressures. Digital gauges provide exact measurements and sometimes embrace options like information logging, making them useful for technicians.

Capabilities of AC Gauges in a Setup

In a typical AC gauge setup, two gauges are important: a high-pressure gauge and a low-pressure gauge. The high-pressure gauge measures the stress within the system’s high-pressure aspect, which is often related to the compressor. The low-pressure gauge measures the stress on the low-side of the system, typically linked to the evaporator. These readings are important for understanding the general stress stability and refrigerant circulation throughout the system.

Typical Stress Ranges for R134a

The stress ranges for R134a in numerous system situations range considerably. In a correctly functioning system, the low-side stress will sometimes fall between 20-50 PSI (kilos per sq. inch) and the high-side stress will usually be between 150-300 PSI, although these values can change primarily based on the ambient temperature and system load. A major deviation from these ranges can point out an issue.

For instance, excessively excessive stress might signify a blockage or a compressor difficulty. Conversely, low stress might point out a leak or inadequate refrigerant.

Comparability of Gauge Readings

Evaluating readings on various kinds of gauges, comparable to analog and digital, is necessary. Analog gauges typically provide a visible illustration of stress fluctuations, which can assist in shortly figuring out developments. Digital gauges, however, present exact numerical values, permitting for extra detailed evaluation. Whereas each sorts are helpful, the selection is dependent upon the particular wants of the technician and the complexity of the duty.

Connecting AC Gauges to a System

Connecting AC gauges to a system includes a number of essential steps. First, make sure the system is correctly shut off and remoted. Then, the gauges are linked to the suitable ports on the manifold, making certain the right high-side and low-side connections. Lastly, the gauges must be calibrated to zero earlier than taking any readings. This course of is essential for correct measurements.

Gauge Readings in Varied System States

The next desk supplies examples of gauge readings in numerous system states, together with low stress and excessive stress.

| System State | Low-Facet Stress (PSI) | Excessive-Facet Stress (PSI) |

|---|---|---|

| Low Stress | Under 20 PSI | Under 150 PSI |

| Regular | 20-50 PSI | 150-300 PSI |

| Excessive Stress | Above 50 PSI | Above 300 PSI |

Studying the Gauges: How To Learn Ac Gauges R134a

Mastering AC gauge readings is essential for diagnosing and troubleshooting air con programs. Correct stress measurements are important for correct refrigerant charging, leak detection, and total system efficiency. Understanding the nuances of high-side and low-side pressures, coupled with vacuum gauge readings, empowers technicians to deal with points successfully and effectively.

Decoding Stress Readings

Correct stress readings are important for efficient AC system upkeep. Stress gauges, sometimes dual-port items, show stress in kilos per sq. inch (psi). The high-side gauge measures stress within the condenser, whereas the low-side gauge measures stress within the evaporator. These pressures fluctuate primarily based on system working situations.

Figuring out Correct Stress Values

Exact stress readings are obtained by making certain the gauge is appropriately linked to the AC system ports. Confirm the gauge’s accuracy by evaluating it to a recognized commonplace stress. Any discrepancy requires recalibration. A correctly functioning gauge, together with a standardized process, supplies dependable information.

Differentiating Excessive-Facet and Low-Facet Pressures

Figuring out high-side and low-side pressures is prime to diagnosing AC points. The high-side stress, sometimes increased, displays the condenser’s operation. The low-side stress, decrease, signifies the evaporator’s efficiency. Misinterpreting these readings can result in improper repairs and probably additional injury. Figuring out the standard stress ranges for numerous working situations aids on this differentiation.

Utilizing a Vacuum Gauge with AC Gauges

A vacuum gauge, typically used together with AC gauges, measures the extent of vacuum within the AC system. A vacuum check helps detect leaks, assess the situation of the system’s seals, and ensures correct refrigerant evacuation. This step is significant earlier than including refrigerant to the system.

Typical Gauge Readings for Varied Circumstances

| Working Situation | Excessive-Facet Stress (psi) | Low-Facet Stress (psi) | Vacuum Gauge Studying (inHg) |

|---|---|---|---|

| Charging (R134a) | 75-100 | 20-40 | 28-30 |

| Leak Detection | Considerably decrease than regular | Considerably decrease than regular | Low or no vacuum |

| System Overcharge | Excessively excessive | Excessively excessive | N/A |

| System Undercharge | Excessively low | Excessively low | N/A |

| System Malfunction (e.g., compressor failure) | Unusually excessive or low | Unusually excessive or low | N/A |

The desk above supplies a basic guideline. Precise readings can range primarily based on ambient temperature, system sort, and different elements. All the time seek the advice of the particular specs for the automobile or tools being serviced.

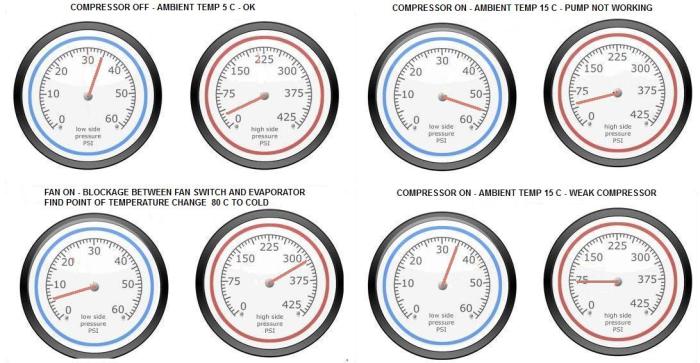

Widespread AC System Points and Gauge Readings

Troubleshooting air con (AC) programs typically includes understanding the readings in your AC gauges. Figuring out the best way to interpret these readings can assist you pinpoint the supply of an issue, whether or not it is a easy refrigerant leak or a extra advanced difficulty. This part delves into widespread AC system issues and their related gauge studying patterns, enabling you to successfully diagnose and deal with AC malfunctions.Understanding the connection between gauge readings and the underlying points inside your AC system is essential for efficient troubleshooting.

By correlating the stress and temperature readings on the gauges with potential system issues, you’ll be able to shortly establish the basis trigger and implement the required repairs.

Refrigerant Leaks

Refrigerant leaks are a frequent explanation for AC system failures. Leaks result in a discount within the refrigerant cost, impacting the system’s capacity to chill successfully. Gauge readings are important in detecting these leaks. A major drop within the system’s stress, typically accompanied by a lower within the refrigerant degree, suggests a leak. The readings on the low-side gauge will probably be considerably decrease than anticipated, whereas the high-side gauge might present a low stress as effectively.

This discrepancy signifies a lack of refrigerant. Diagnosing a leak includes meticulously checking all connections and elements for indicators of injury or leaks.

Undercharged AC System

An undercharged AC system is one other widespread downside. An inadequate refrigerant cost leads to the system not functioning optimally. The low-side gauge stress will probably be considerably decrease than the anticipated vary for the given temperature, indicating a shortfall within the refrigerant cost. This undercharging will lead to lowered cooling capability and probably result in different points.

Overcharged AC System

Conversely, an overcharged AC system can be problematic. An extreme refrigerant cost can create stress buildup within the system, hindering correct performance. Excessive-side gauge stress will constantly be increased than the traditional vary for the given temperature. This overcharging may cause the compressor to overheat and probably fail.

Significance of Correct Refrigerant Cost Ranges

Sustaining the right refrigerant cost is paramount for optimum AC efficiency. A well-balanced cost ensures environment friendly warmth switch, maximizing cooling capability. Insufficient or extreme refrigerant ranges compromise the system’s effectiveness, leading to lowered cooling, elevated vitality consumption, and potential injury to elements. Understanding and sustaining the right cost ranges is important for the long-term well being and effectivity of your AC system.

Examples of Widespread AC System Issues and Corresponding Gauge Readings

| AC System Downside | Low-Facet Gauge Studying | Excessive-Facet Gauge Studying | Rationalization |

|---|---|---|---|

| Refrigerant Leak | Considerably decrease than anticipated | Probably low, or might present stress fluctuation | The decrease stress signifies a lack of refrigerant because of a leak. |

| Undercharged System | Considerably decrease than anticipated vary | Decrease than anticipated | Inadequate refrigerant cost, decreasing cooling capability. |

| Overcharged System | Inside anticipated vary, however high-side stress is unusually excessive | Considerably increased than anticipated vary | Extreme refrigerant cost, probably inflicting compressor overheating. |

| Blocked Condenser | Low | Excessive | Decreased airflow results in increased stress on the high-side, and decrease stress on the low-side. |

Troubleshooting AC Techniques Based mostly on Gauge Readings

Mastering AC system troubleshooting hinges on understanding gauge readings. Correct interpretation of stress differentials and refrigerant circulation supplies useful insights into potential points, permitting for environment friendly and efficient repairs. This important talent can save money and time by pinpointing the basis explanation for issues, stopping pointless replacements, and making certain optimum AC efficiency.Troubleshooting AC programs requires a scientific strategy, beginning with an intensive understanding of the gauge readings.

By analyzing the stress readings on the manifold gauges, technicians can shortly establish numerous issues, comparable to leaks, refrigerant depletion, or compressor malfunctions. This information empowers them to carry out focused repairs, minimizing downtime and maximizing system effectivity.

Figuring out Low-Stress/Excessive-Stress Points

Low-pressure/high-pressure points are widespread in AC programs. Low-pressure situations typically point out inadequate refrigerant, a leak, or a malfunctioning compressor. Excessive-pressure situations, however, counsel refrigerant overcharge, blocked condenser coils, or a compressor malfunction. Correct gauge readings assist differentiate between these situations.

Troubleshooting Eventualities and Options

A scientific strategy to troubleshooting includes fastidiously inspecting the gauge readings. The next examples spotlight widespread situations and their corresponding options.

- Low-pressure/high-pressure readings: This typically signifies a leak. An intensive visible inspection of the system, together with the strains and elements, is important to find the leak. As soon as the leak is recognized, restore it utilizing acceptable instruments and methods. After the restore, recharge the system with the right amount of refrigerant, making certain correct gauge readings.

- Excessive-pressure/high-pressure readings: This implies an overcharge of refrigerant. To deal with this, fastidiously evacuate the surplus refrigerant to realize optimum stress readings. Additionally, examine the condenser coils for any obstructions or blockages. Cleansing the coils will enhance warmth dissipation and stress ranges.

- Low-pressure/low-pressure readings: This example might point out inadequate refrigerant, a leak, or a compressor malfunction. A refrigerant leak must be recognized and repaired instantly. If a leak is just not current, examine the compressor’s performance and refrigerant cost degree.

Security Precautions

Security precautions are paramount throughout AC system upkeep. Working with refrigerants requires adherence to strict security protocols. All the time put on acceptable private protecting tools (PPE), comparable to security glasses, gloves, and a respirator. Guarantee the world is well-ventilated to stop refrigerant inhalation. By no means work on a system that’s beneath stress with out correct security measures.

Repairing a Leak, learn ac gauges r134a

- Establish the leak: Utilizing a leak detector, pinpoint the precise location of the leak. Visible inspection is usually useful together with the leak detector.

- Isolate the system: Shut off the ability to the compressor and isolate the AC system from the remainder of the system to stop any unintended start-up.

- Restore the leak: Make use of the suitable restore technique, comparable to soldering, brazing, or utilizing sealant, relying on the kind of leak and part concerned. Make sure the restore is safe and leak-free.

- Recharge the system: Fastidiously add the right amount of refrigerant to the system to revive optimum stress readings. Use a gauge to observe the cost degree.

- Take a look at the system: After recharging, run the system and monitor its efficiency. Examine the gauge readings to make sure the system is working throughout the correct stress vary.

Troubleshooting Desk

| AC System Difficulty | Low-Stress Gauge Studying | Excessive-Stress Gauge Studying | Troubleshooting Steps |

|---|---|---|---|

| Refrigerant Leak | Low | Excessive or Low | Find and restore the leak; recharge the system. |

| Refrigerant Overcharge | Excessive | Excessive | Evacuate extra refrigerant; regulate cost to correct degree. |

| Blocked Condenser Coils | Low | Excessive | Clear the condenser coils; examine for obstructions. |

| Compressor Malfunction | Low or Excessive | Excessive or Low | Examine compressor performance; change if essential. |

Sustaining AC System Efficiency with Gauge Readings

Maintaining your air con system working easily and effectively hinges on constant upkeep, and gauge readings play an important function on this course of. Common checks will let you establish potential issues early, stopping expensive repairs and increasing the system’s lifespan. Understanding the best way to interpret these readings empowers you to optimize efficiency and guarantee your consolation.

Optimizing AC System Effectivity By Gauge Readings

Correct gauge readings present useful insights into the situation of your AC system. Low refrigerant ranges, for instance, typically manifest as a lower-than-normal stress studying on the low-side gauge. Equally, excessive stress readings can point out a blockage or different points within the system. By constantly monitoring these readings, you’ll be able to proactively deal with issues earlier than they escalate.

Finest Practices for Stopping AC System Issues

Proactive upkeep is vital to stopping expensive repairs and making certain optimum AC system efficiency. Common servicing, together with checking refrigerant ranges and making certain correct airflow, are important steps. A well-maintained system will function extra effectively, resulting in decrease vitality consumption and an extended lifespan. A standard difficulty, as an illustration, is refrigerant leaks. Detecting them early by common gauge readings can prevent a big amount of cash in the long term.

Significance of Common AC System Upkeep

Common upkeep isn’t just a advice; it is important for sustaining a useful and environment friendly AC system. Routine checks and servicing, guided by gauge readings, can forestall breakdowns, reduce vitality consumption, and lengthen the general lifespan of your tools. Ignoring routine upkeep can result in extra severe, costly repairs down the road.

Connection Between Gauge Readings and AC System Lifespan

The correlation between constant gauge readings and the longevity of your AC system is plain. Common monitoring of pressures and temperatures, as indicated by the gauges, permits you to catch delicate points early, like leaks or blockages. This early intervention can forestall vital injury and lengthen the lifespan of the compressor, condenser, and different essential elements. A well-maintained system, monitored with gauge readings, will typically have a for much longer operational life.

Common AC System Upkeep Guidelines

This guidelines supplies a structured strategy to sustaining your AC system, incorporating gauge studying checks.

- Visible Inspection: Examine the system for any seen injury or leaks. Search for indicators of corrosion or unfastened connections.

- Refrigerant Degree Examine: Use the low-side gauge to find out the refrigerant degree. Low ranges necessitate a recharge. Word the readings and evaluate them with producer specs.

- Stress Readings: Examine high-side and low-side pressures. Guarantee these readings fall throughout the beneficial vary on your system sort. Excessive or low stress readings may point out a blockage, leak, or different difficulty.

- Temperature Readings: Examine the temperatures at numerous factors within the system. Anomalies in temperature readings can point out a malfunction. Evaluate readings with the anticipated values on your particular AC unit.

- Airflow Examine: Confirm correct airflow by the condenser coils. Any blockages will have an effect on cooling effectivity and must be addressed instantly. Observe the fan operation and the general airflow sample.

- Part Lubrication: Lubricate transferring components, such because the compressor and fan motor, as beneficial by the producer. It will keep easy operation.

- Electrical Connections: Examine all electrical connections for any indicators of injury or corrosion. Free connections can result in electrical points and injury. Confirm all connections are safe and in good situation.

By following this guidelines and constantly monitoring your AC system’s gauge readings, you’ll be able to keep optimum efficiency, lengthen its lifespan, and reduce expensive repairs.

End result Abstract

In conclusion, mastering the best way to learn AC gauges for R134a refrigerant is a basic talent for HVAC professionals. This information has offered an intensive understanding of gauge setups, studying methods, widespread points, and troubleshooting strategies. By following the steps Artikeld, you will be outfitted to diagnose and restore AC programs effectively and safely. Bear in mind to prioritize security precautions all through the method.

Key Questions Answered

What are the standard stress ranges for R134a in a low-pressure/high-pressure system?

Low-side stress sometimes ranges from 20-40 PSI, whereas high-side stress is round 200-300 PSI. Nevertheless, actual ranges rely upon the particular system and working situations.

How can I inform if my AC system is undercharged or overcharged by wanting on the gauge readings?

Undercharged programs typically present low stress on each high-side and low-side gauges. Overcharging leads to excessive stress on either side, probably exceeding the secure working vary.

What are some widespread security precautions when working with AC gauges and refrigerant?

All the time put on acceptable security gear, like security glasses and gloves. Guarantee correct air flow, and work in a well-lit space. By no means work alone, and concentrate on potential refrigerant leaks.

What’s the distinction between high-side and low-side pressures on AC gauges?

Excessive-side stress pertains to the condenser, whereas low-side stress refers back to the evaporator. Understanding the distinction in readings is significant for correct prognosis.