The right way to shrink an o ring is a vital talent for anybody working with equipment and tools. Understanding the nuances of shrinking o-rings is crucial for guaranteeing optimum efficiency and stopping potential malfunctions. From exact sizing to numerous shrinking methods, this complete information will equip you with the information to shrink o-rings successfully and safely.

This information gives a step-by-step method to shrinking o-rings, protecting the whole lot from the elemental rules of o-ring operate to the particular instruments and security precautions wanted for the job. We’ll delve into the completely different strategies, contemplating elements like materials compatibility and potential dangers, all offered in a transparent and accessible method. With sensible examples and detailed illustrations, you will be well-equipped to sort out o-ring shrinkage tasks with confidence.

Introduction to O-Ring Shrinkage

O-rings are round, elastomeric seals utilized in all kinds of mechanical purposes. Their main operate is to create a leak-proof seal between two mating surfaces, stopping fluids, gases, or different supplies from escaping. O-rings are essential for sustaining stress, containment, and total system integrity. They’re present in the whole lot from plumbing fixtures to aerospace elements.Correct O-ring choice and set up are essential for his or her effectiveness.

Generally, to make sure a decent, leak-free seal, or to accommodate particular design necessities, shrinking an O-ring is important. This course of entails decreasing the O-ring’s diameter to create a comfortable match inside its housing. That is generally executed for high-pressure purposes, the place an ideal seal is paramount.

O-Ring Sizing and Choice Significance

Correct sizing and materials number of O-rings are elementary to attaining a dependable seal. Inaccurate sizing can result in leaks, lowered efficiency, or potential tools injury. Materials compatibility with the encompassing atmosphere and working situations is equally vital to stop degradation or failure. Consideration of things like temperature, stress, and chemical compatibility is important for long-term seal integrity.

Frequent Situations Requiring O-Ring Shrinkage

O-ring shrinkage is commonly employed in high-pressure purposes to make sure a exact and tight seal. That is notably vital in hydraulic techniques, pneumatic techniques, and different purposes requiring leak-free operation. Moreover, it may be employed to make sure the seal stays intact throughout operation, particularly at elevated temperatures or when excessive pressures are concerned. One other occasion is when the housing dimensions are essential and a regular O-ring can’t match with out impacting efficiency.

O-Ring Supplies, Functions, and Shrinkage Strategies

Correct O-ring choice is determined by the particular software’s necessities. Totally different supplies exhibit completely different properties and are suited to varied working situations. The desk under gives a common overview of widespread O-ring supplies, their typical purposes, and the shrinkage strategies generally employed.

| O-ring Materials | Typical Functions | Shrinkage Strategies |

|---|---|---|

| Nitrile (NBR) | Normal-purpose seals in varied fluids and average temperatures. | Warmth shrinking, mechanical compression |

| Fluorocarbon (Viton) | Excessive-temperature, chemical-resistant purposes, equivalent to automotive elements and aerospace elements. | Warmth shrinking, mechanical compression, particular procedures for particular purposes |

| Silicone | Seals requiring flexibility and huge temperature ranges, together with medical units. | Warmth shrinking, mechanical compression |

| Ethylene Propylene (EPDM) | Seals in oil, water, and a few chemical compounds. | Warmth shrinking, mechanical compression |

Be aware: The precise shrinkage technique used will rely on the fabric and software.

Strategies for Shrinking O-Rings

O-rings, essential elements in varied mechanical techniques, typically require exact dimensional changes for optimum efficiency and sealing. Shrinking an O-ring modifies its inner diameter, guaranteeing a decent match inside its meant housing. This course of is important for stopping leaks and guaranteeing a dependable seal.Totally different strategies for shrinking O-rings provide various levels of management, precision, and security. Understanding the nuances of every technique is crucial for attaining the specified final result whereas minimizing potential dangers.

Warmth Shrinking

Warmth shrinking makes use of managed heating to change the O-ring’s materials properties, inflicting it to contract and conform to a smaller diameter. This technique gives exact management over the shrinkage course of, enabling changes tailor-made to particular purposes.

- Step-by-Step Process: Guarantee correct air flow and security tools. Immerse the O-ring in a managed temperature tub, monitoring the temperature intently. Keep the O-ring throughout the tub for a predetermined period. Take away the O-ring and permit it to chill steadily, stopping thermal shock. This step-by-step method is essential for profitable shrinkage and avoiding injury to the O-ring.

- Security Precautions: All the time put on applicable security gear, together with heat-resistant gloves and eye safety. Use calibrated temperature controls to keep away from exceeding the fabric’s melting level. By no means overheat the O-ring, as this will result in irreversible injury or deformation. Guarantee satisfactory air flow to stop the discharge of doubtless dangerous fumes. Correct dealing with and storage of supplies are essential.

- Benefits: Excessive precision in shrinkage management, suitability for varied O-ring supplies, and relative cost-effectiveness for moderate-scale purposes. Moreover, the tactic gives good management over the ultimate dimensions, making it helpful in purposes demanding tight tolerances.

- Disadvantages: Requires specialised tools and cautious monitoring of temperature and time. Doable materials degradation or deformation if not dealt with appropriately. Potential for warping or uneven shrinkage if not carried out beneath managed situations. It may be slower than different strategies.

Chilly Shrinking

Chilly shrinking makes use of specialised methods to use mechanical stress to the O-ring, inflicting it to contract with out using warmth. This technique is commonly used for supplies which might be delicate to excessive temperatures or for conditions the place warmth shrinking shouldn’t be possible.

- Step-by-Step Process: Using specialised instruments, fastidiously apply managed stress to the O-ring. Keep the stress for a predefined period. Launch the stress steadily to keep away from injury to the O-ring. Examine the O-ring for any seen deformation or defects.

- Security Precautions: Use applicable security tools, together with protecting eyewear and gloves. Make use of calibrated stress instruments to keep away from exceeding the O-ring’s mechanical energy. Common upkeep and calibration of apparatus are very important for security and precision. Rigorously monitor the whole course of to stop unexpected points.

- Benefits: Appropriate for heat-sensitive supplies, sooner than warmth shrinking in some circumstances, and comparatively low danger of fabric degradation.

- Disadvantages: Much less exact than warmth shrinking, potential for injury to the O-ring from extreme stress, and should require specialised instruments.

Comparability Desk

| Methodology | Velocity | Precision | Price |

|---|---|---|---|

| Warmth Shrinking | Reasonable | Excessive | Reasonable |

| Chilly Shrinking | Excessive | Reasonable | Excessive (as a result of specialised instruments) |

Potential Dangers

Potential dangers related to each warmth and chilly shrinking embrace materials injury, deformation, and uneven shrinkage. Improper dealing with or exceeding the fabric’s tolerances can result in important issues. All the time prioritize security precautions to mitigate these dangers. Thorough understanding of the particular materials and its limitations is crucial.

Elements Affecting O-Ring Shrinkage

Profitable O-ring shrinkage depends on cautious consideration of a number of key elements. These elements affect the end result of the shrinking course of and the following efficiency of the assembled element. Understanding these influences is essential for attaining a exact and dependable match, stopping leaks, and guaranteeing the longevity of the ultimate product.

Temperature Affect

Temperature considerably impacts the shrinkage course of. Modifications in temperature alter the fabric’s properties, straight affecting its contraction fee. Greater temperatures typically result in a better contraction, whereas decrease temperatures end in much less shrinkage. It’s because thermal growth and contraction are inherent properties of supplies. Correct temperature management in the course of the shrinking course of is crucial to attain the specified match.

Variations in temperature can result in inconsistent shrinkage, probably inflicting misalignment or uneven stress distribution.

Materials Properties Affect

Totally different supplies exhibit various levels of shrinkage beneath similar situations. The fabric’s inherent traits, together with its coefficient of thermal growth, play a essential position. The coefficient of thermal growth quantifies how a lot a fabric expands or contracts with temperature adjustments. As an illustration, supplies with larger coefficients of thermal growth will shrink greater than these with decrease coefficients when subjected to the identical temperature lower.

Materials choice is essential to make sure compatibility with the shrinking technique and the anticipated working situations. Moreover, the purity and composition of the fabric can affect the shrinkage traits.

Strain Affect

Strain exerted on the O-ring in the course of the shrinking course of additionally influences the end result. Greater pressures could cause the O-ring to deform extra considerably, probably resulting in better shrinkage. The impact of stress is commonly much less pronounced than temperature however can nonetheless be a contributing issue. Furthermore, stress can have an effect on the fabric’s elasticity and resistance to deformation, which ought to be thought of in the course of the number of shrinkage strategies and supplies.

Choice of Shrinkage Strategies

Accounting for the influences of temperature, materials properties, and stress is essential when deciding on an appropriate shrinkage technique. Every technique has its particular limitations and purposes. For instance, a technique counting on a managed temperature gradient could be ideally suited for supplies with excessive coefficients of thermal growth. The selection of technique is determined by the particular materials, the specified degree of precision, and the working atmosphere.

Cautious consideration of the elements influencing O-ring shrinkage will result in the number of an optimum shrinkage technique, guaranteeing a profitable and dependable seal.

Materials Response to Shrinkage Strategies

The desk under illustrates how completely different supplies reply to numerous shrinking methods. This desk highlights the variations in shrinkage traits for various supplies. Be aware that these are generalized responses and particular outcomes could differ primarily based on the precise materials composition, processing parameters, and environmental situations.

| Materials | Vacuum Shrinkage | Warmth Shrinkage | Strain Shrinkage |

|---|---|---|---|

| Silicone Rubber | Good, however requires exact management | Wonderful, predictable | Reasonable, could require extra precautions |

| Nitrile Rubber | Truthful, could require modifications | Good, however potential for warping | Good, however might be affected by stress sensitivity |

| EPDM | Wonderful, dependable | Wonderful, however prone to warmth injury | Good, comparatively unaffected by stress |

Instruments and Tools for O-Ring Shrinkage

Correctly shrinking an O-ring requires specialised instruments and tools tailor-made to the chosen technique. Choosing the right instruments ensures a exact and secure shrinking course of, resulting in a sturdy and leak-proof seal. Cautious consideration of the particular tools wanted for every technique is essential for profitable outcomes.

Instruments for Thermal Shrinkage

Cautious number of instruments is essential for the success of thermal shrinkage. The correct instruments assure a exact and secure shrinking course of, leading to a dependable and leak-proof seal. The tools wants to exactly management the warmth software and guarantee uniform heating.

- Warmth Gun or Warmth Block: A warmth gun gives focused warmth for localized shrinking. A warmth block gives a extra managed, even heating floor, typically used for bigger or extra advanced O-rings. Warmth weapons are typically extra versatile, whereas warmth blocks provide superior temperature management and uniformity, notably for intricate shapes or a number of O-rings. Select the software primarily based on the dimensions and form of the O-ring and the complexity of the applying.

A warmth gun permits for exact concentrating on and changes to the warmth output, ideally suited for smaller, intricate O-rings or areas requiring localized heating. Warmth blocks, typically with temperature gauges and adjustable settings, provide a constant heating supply, essential for bigger O-rings and a number of O-rings that want constant temperature publicity. Examples embrace electrical or gas-powered warmth weapons and varied kinds of electrically heated blocks.

- Thermometer: Important for monitoring the temperature in the course of the shrinking course of. A digital thermometer with an correct temperature vary is really useful for precision management. The thermometer ought to be calibrated often to make sure correct readings, and its placement ought to be strategic for essentially the most correct temperature measurements. This permits for the exact upkeep of the specified temperature to stop over-heating and injury to the O-ring.

- Measuring Instruments (Caliper, Micrometer): Correct measurement of the O-ring’s dimensions is important. Calipers and micrometers enable for exact measurements earlier than and after shrinking to verify the shrinkage is inside acceptable tolerances. The usage of correct measuring instruments is crucial for guaranteeing that the O-ring suits the applying correctly and that any potential issues are detected and addressed earlier than the shrinking course of begins.

Common calibration of the measuring instruments is essential for guaranteeing accuracy. Varied kinds of calipers and micrometers can be found, every with various precision and measurement ranges. Choose the suitable software primarily based on the dimensions and form of the O-ring and the required degree of accuracy.

Instruments for Mechanical Shrinkage

Mechanical shrinkage strategies necessitate particular tools to attain the specified deformation of the O-ring.

- Compression Instruments: These instruments apply managed stress to scale back the O-ring’s dimension. Specialised compression instruments, designed for varied O-ring styles and sizes, are required. These instruments guarantee exact stress software and management, avoiding injury to the O-ring. Sorts of compression instruments embrace hydraulic presses, screw-driven presses, or specialised hand-held instruments, every with various capacities and stress ranges.

- Calibration Fixtures: These fixtures exactly place and maintain the O-ring in the course of the shrinking course of, guaranteeing correct alignment and constant stress software. They keep the specified place and form of the O-ring, essential for constant outcomes. The design of calibration fixtures typically varies primarily based on the form and dimension of the O-ring and the kind of software.

Security Tools

| Process | Security Tools |

|---|---|

| Thermal Shrinkage | Warmth-resistant gloves, security glasses, hearth extinguisher, and applicable private protecting tools (PPE). |

| Mechanical Shrinkage | Security glasses, gloves, and applicable private protecting tools (PPE) to deal with the particular mechanical instruments. |

Device Dealing with and Upkeep

Correct dealing with and upkeep of instruments are essential to make sure security and longevity. Common upkeep prevents surprising failures and maximizes software lifespan.

- Cleansing: Common cleansing of instruments prevents build-up of contaminants, which might have an effect on their efficiency. Cleansing ensures that the instruments are in optimum situation to be used, decreasing the danger of accidents or malfunctions. Cleansing strategies differ relying on the fabric of the software.

- Calibration: Common calibration of measuring instruments ensures accuracy, essential for attaining exact shrinkage outcomes. Calibration checks the precision of the instruments’ measurements to make sure correct outcomes and keep away from potential errors.

- Inspection: Common inspection of instruments for injury or put on is crucial to stop accidents. This contains checking for any cracks, dents, or unfastened elements. Inspection of instruments earlier than every use helps forestall potential hazards.

Potential Hazards and Security Measures

Cautious consideration of potential hazards is important for a secure shrinking course of.

- Burns: Thermal shrinkage entails excessive temperatures. Put on heat-resistant gloves and protecting eyewear. Keep a secure distance from the warmth supply.

- Tools Malfunctions: Mechanical instruments can malfunction. Examine instruments earlier than use and guarantee correct upkeep to stop accidents. Use applicable security tools throughout operation.

- Materials Harm: Improper dealing with can injury the O-ring or the half it’s put in on. Comply with correct dealing with procedures to keep away from such injury. Use calibrated instruments and keep managed shrinking procedures.

Security Precautions Throughout O-Ring Shrinkage

Correct security precautions are paramount in the course of the O-ring shrinkage course of to stop accidents and accidents. Adhering to those measures ensures a secure working atmosphere and minimizes the danger of potential hazards related to the process. Failure to prioritize security can result in severe penalties, starting from minor burns to extreme accidents.

Important Security Precautions

Secure practices are essential for avoiding accidents throughout O-ring shrinkage. Following these precautions considerably reduces the danger of hurt to personnel and tools. Sustaining a secure atmosphere is important for all concerned within the course of.

- All the time put on applicable private protecting tools (PPE). PPE is crucial for safeguarding in opposition to potential hazards in the course of the shrinking course of. It’s essential to make use of the right protecting gear to stop publicity to warmth, chemical compounds, or different dangerous substances.

- Completely examine tools earlier than use. Pre-use inspections of all tools, together with heating parts, clamps, and holding units, are essential to determine any potential malfunctions or injury. This safety measure helps keep away from surprising failures in the course of the process.

- Keep a transparent and arranged workspace. A well-organized workspace minimizes the danger of tripping hazards or accidents. Guaranteeing adequate area across the work space helps to keep away from collisions and stop accidents.

- Use correct dealing with methods for the O-rings and elements. Rigorously dealing with O-rings and elements, avoiding sharp edges or tough surfaces, helps forestall cuts or abrasions. Right dealing with prevents injury to the O-rings and surrounding supplies.

Potential Hazards and Avoidance

Understanding potential hazards is essential for implementing preventive measures. Cautious consideration of the hazards and their potential penalties will contribute to a secure working atmosphere.

- Thermal Burns: Excessive temperatures generated in the course of the shrinking course of pose a big danger of thermal burns. Utilizing heat-resistant gloves and aprons minimizes the danger of burns. The usage of correct thermal insulation is crucial.

- Chemical Publicity: Some supplies used within the course of, like lubricants, may launch dangerous chemical compounds. Air flow and applicable respiratory safety are essential to attenuate publicity. Following materials security information sheets (MSDS) is crucial to make sure correct dealing with.

- Tools Malfunction: Defective tools could cause surprising incidents. Common upkeep and inspection of the tools forestall potential malfunctions. This reduces the probability of accidents attributable to tools failures.

- Dealing with Accidents: Improper dealing with of O-rings and elements may end up in cuts, abrasions, or different accidents. Utilizing correct instruments and methods can considerably cut back these dangers. Utilizing padded dealing with surfaces is useful in stopping injury to the O-rings.

Emergency Procedures

Establishing clear emergency procedures is important in case of accidents. These procedures ought to be practiced and readily accessible to personnel.

| Hazard | Prevention Methodology | PPE |

|---|---|---|

| Thermal Burns | Use heat-resistant gloves and aprons, keep correct distance from warmth supply | Warmth-resistant gloves, aprons, security glasses |

| Chemical Publicity | Ample air flow, use of respirators, comply with MSDS | Respirators, security glasses, gloves |

| Tools Malfunction | Common tools upkeep, correct use of apparatus | Security glasses, gloves, applicable protecting gear primarily based on tools |

| Dealing with Accidents | Use applicable instruments, deal with elements fastidiously | Gloves, security glasses, protecting clothes |

In case of an accident, rapid motion is essential. Emergency procedures ought to embrace notifying supervisors, offering first assist, and contacting emergency providers. Implementing correct first assist protocols is essential in minimizing the severity of accidents.

Troubleshooting O-Ring Shrinkage Points: How To Shrink An O Ring

O-ring shrinkage, whereas an important course of for sealing purposes, can typically encounter surprising challenges. Correct troubleshooting is crucial to determine and resolve these points effectively, stopping expensive downtime and guaranteeing the integrity of the ultimate meeting. This part delves into widespread issues, their causes, and efficient options.Figuring out the foundation explanation for shrinkage issues is commonly essentially the most essential step.

Cautious examination of the method, supplies, and instruments concerned can pinpoint the supply of the problem, resulting in a extra focused and efficient resolution.

Frequent Shrinkage Issues and Options

Understanding the potential pitfalls within the o-ring shrinkage course of is vital to attaining profitable outcomes. These issues typically stem from materials incompatibility, incorrect methods, or insufficient tools upkeep.

- Materials Choice Points: Incompatible supplies between the o-ring and the shrinking software or the applying itself can result in improper shrinkage. As an illustration, utilizing a metal mandrel with a polymer o-ring could cause the o-ring to deform and even fracture in the course of the heating course of. Choosing an o-ring materials with a coefficient of thermal growth that matches the half it’s going to seal is essential.

Utilizing a fabric compatibility chart can help on this choice. Think about the working temperature vary and the potential for stress rest in the course of the shrinkage course of when selecting the o-ring materials.

- Improper Heating Strategies: Uneven heating can result in inconsistent shrinkage, leading to a poorly sealed or broken o-ring. That is particularly vital with advanced geometries. Make sure the heating technique (e.g., oven, scorching plate) is able to offering uniform warmth distribution throughout the o-ring and the half being shrunk onto. Utilizing a calibrated thermometer is vital for exact temperature management, and it’s essential to keep away from exceeding the o-ring’s most working temperature.

The heating fee ought to be gradual and managed to keep away from thermal shock.

- Tools Malfunctions: Malfunctioning tools, equivalent to a heating system with inaccurate temperature management, also can result in inconsistent or improper shrinkage. Examine the tools often for correct functioning and calibration. Points with the shrinking software’s design or improper software alignment also can contribute to issues. The software should present a exact and uniform clamping stress to make sure the o-ring conforms to the meant form and dimension.

- Incorrect Cooling Procedures: Speedy cooling could cause residual stresses and have an effect on the ultimate form of the o-ring. Permitting the o-ring to chill slowly and evenly may also help keep its desired form and dimensional stability. A managed cooling atmosphere, equivalent to a temperature-controlled chamber, may also help obtain this. The cooling fee ought to be tailor-made to the particular o-ring materials to stop warping.

Troubleshooting Steps for Totally different Strategies

Particular troubleshooting steps differ relying on the tactic used for o-ring shrinkage. For instance, troubleshooting oven-based shrinkage strategies differs from these utilizing scorching plates or specialised shrinking instruments.

- Oven-based Shrinkage: Confirm the oven’s temperature calibration and guarantee constant warmth distribution. If the o-ring shouldn’t be shrinking correctly, examine for air pockets or uneven heating. Alter the heating time and temperature as wanted. Make sure the o-ring is positioned within the middle of the oven for uniform heating.

- Scorching Plate-based Shrinkage: Examine for uneven heating on the recent plate floor. Make use of a heat-resistant pad beneath the o-ring and the half to make sure even warmth switch. Use a calibrated thermometer to watch the temperature exactly. Rigorously alter the warmth setting and the period of the heating course of.

Potential Points and Options Desk

| Potential Concern | Doable Answer |

|---|---|

| O-ring doesn’t shrink | Confirm right temperature, heating time, and o-ring materials compatibility. Guarantee correct clamping stress throughout shrinkage. |

| O-ring cracks or tears throughout shrinkage | Cut back heating fee and temperature, examine materials compatibility, and guarantee correct clamping stress. Examine the o-ring for any pre-existing injury. |

| O-ring shrinks inconsistently | Guarantee uniform warmth distribution, use a calibrated thermometer, and confirm the shrinking software’s alignment. Examine for air pockets across the o-ring. |

| O-ring displays warping or deformation | Management the cooling fee, guarantee correct materials choice, and examine for residual stresses. Keep away from fast cooling. |

Case Research of O-Ring Shrinkage Functions

O-ring shrinkage, a essential course of in varied industries, ensures exact sealing and optimum efficiency. Understanding the application-specific challenges and the strategies used to attain profitable shrinkage is essential for engineers and technicians. This part explores real-world examples, highlighting the particular necessities, supplies, strategies, and outcomes of O-ring shrinkage in various industries.Actual-world purposes of O-ring shrinkage typically contain advanced geometries and materials properties.

The success of the shrinkage course of depends on cautious consideration of things like materials compatibility, temperature variations, and the specified last dimensions of the O-ring. Every case examine showcases a special method to attaining the specified seal.

Automotive Business

The automotive business incessantly makes use of O-ring shrinkage for sealing in varied elements. Correct sealing is paramount in engine elements, transmission techniques, and gasoline traces to stop leaks and guarantee optimum efficiency.

- Engine Valve Cowl Seals: O-rings shrink-fit to the valve cowl, offering a sturdy seal in opposition to oil leakage. The exact dimensional tolerances required for these seals demand meticulous management over the shrinkage course of.

- Turbocharger Seals: Excessive-temperature and high-pressure environments in turbochargers necessitate O-rings that keep their seal integrity beneath excessive situations. Shrinkage strategies should account for these situations to make sure long-term efficiency.

“In turbocharger purposes, the shrinkage course of have to be optimized to make sure the O-ring maintains its sealing functionality at working temperatures exceeding 400°C. This requires cautious number of supplies with excessive thermal stability.”

Aerospace Business, The right way to shrink an o ring

The aerospace business calls for distinctive sealing reliability, particularly in high-stress environments. O-ring shrinkage performs an important position in guaranteeing leak-free techniques in essential elements.

- Rocket Engine Seals: O-rings, shrunk to suit tightly inside rocket engine elements, be sure that high-pressure gasoline and oxidizer techniques stay sealed throughout launch and operation. The intense temperatures and pressures in these techniques require supplies that may face up to the cruel situations.

- Satellite tv for pc Communication Programs: Within the satellite tv for pc business, O-rings are used to seal elements in delicate communication techniques. The precision wanted for these purposes necessitates exact management over shrinkage processes to stop any leakage or efficiency degradation.

“For rocket engine seals, specialised supplies like fluorocarbon elastomers, recognized for his or her high-temperature resistance and chemical inertness, are sometimes used along with exact shrinkage strategies.”

Plumbing Business

The plumbing business depends on O-ring shrinkage for sealing in varied water-based purposes. These seals have to be dependable and immune to corrosion.

- Water Pump Seals: O-rings are essential in sustaining the integrity of water pump techniques. O-ring shrinkage ensures a decent seal, stopping water leakage and sustaining the pump’s effectivity.

- Valve Seals: O-rings shrink-fit into valves to make sure dependable sealing and stop water loss. This software calls for supplies that resist water corrosion and chemical degradation.

“In plumbing purposes, O-rings should exhibit distinctive resistance to corrosion and degradation within the presence of water. This requires deciding on supplies with particular chemical compatibility with water and different potential contaminants.”

Chemical Processing

Chemical processing crops require O-rings to face up to the corrosive results of varied chemical compounds. O-ring shrinkage is crucial in creating leak-proof seals for these environments.

- Reactor Vessel Seals: O-rings in reactor vessels are subjected to excessive pressures and a variety of chemical compounds. Shrinkage strategies in these purposes should take into account the particular chemical compatibility and guarantee long-term seal integrity.

- Piping Programs: In chemical piping techniques, O-rings shrink-fit to stop leaks in high-pressure and high-temperature environments. The selection of supplies for these O-rings should take into account the particular chemical compatibility.

“For chemical processing, O-rings should exhibit superior resistance to chemical assault and degradation. This necessitates utilizing supplies which might be chemically inert to the method fluids and supply long-term sealing efficiency.”

Illustrative Examples of O-Ring Shrinkage

O-ring shrinkage is a vital course of in varied industries, guaranteeing correct sealing and stopping leaks. Understanding the varied strategies for shrinking O-rings is crucial for attaining optimum efficiency and stopping expensive failures. This part presents illustrative examples of the O-ring shrinkage course of, highlighting completely different methods and supplies.

Warmth Shrinkage Methodology

The warmth shrinkage technique is a typical and efficient method for shrinking O-rings. This course of entails making use of warmth to the O-ring to scale back its dimension and match it exactly into the specified housing. Correct management of temperature and time is essential for achievement.

Determine 1: Warmth Shrinkage Instance 1

-This picture depicts the preliminary stage of the warmth shrinkage technique. A warmth gun is used to warmth the O-ring, which is positioned on a heat-resistant floor (e.g., a steel plate). The O-ring is manufactured from a selected elastomer, like nitrile rubber. The temperature of the warmth gun is exactly managed to keep away from injury to the O-ring. The warmth gun is positioned fastidiously, guaranteeing uniform heating of the O-ring.

Be aware the particular O-ring materials and the warmth gun settings are essential for profitable shrinking.

Determine 2: Warmth Shrinkage Instance 2

-This stage showcases the O-ring after being heated. The fabric is clearly present process shrinkage as the warmth expands the molecules throughout the materials, permitting it to evolve to the form of the housing. The managed temperature is important to stop the O-ring from turning into distorted or broken. Discover using protecting gear, equivalent to gloves and security glasses, to safeguard the technician’s well-being.

Determine 3: Warmth Shrinkage Instance 3

– The O-ring is now exactly fitted into the housing. The housing is pre-prepared to accommodate the lowered dimension of the O-ring. The shrinkage course of is full, guaranteeing a decent seal. The O-ring is a essential element on this meeting, guaranteeing dependable efficiency.

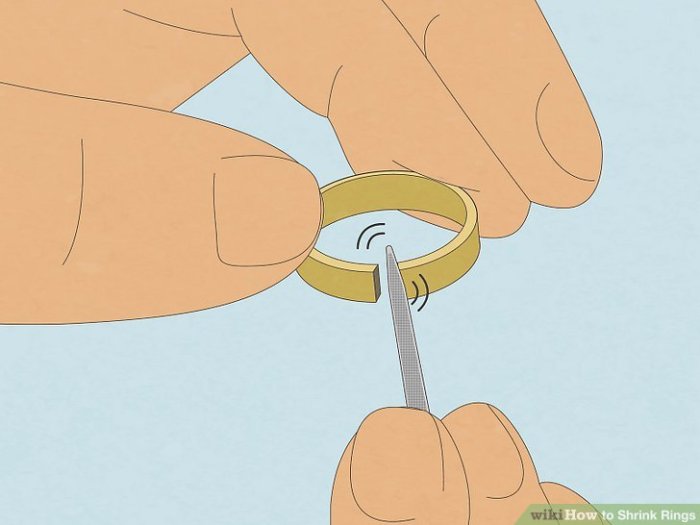

Mechanical Shrinkage Methodology

Mechanical shrinkage strategies use specialised instruments and methods to shrink the O-ring. The exact manipulation of the O-ring materials is essential for correct becoming.

Determine 4: Mechanical Shrinkage Instance 1

-This picture reveals a mechanical shrinking software used to press the O-ring. The software is designed to compress the O-ring materials, which adjustments its dimension. The software is manufactured from sturdy supplies (e.g., metal) to face up to the required stress. The O-ring is a essential element within the system’s sealing, and the mechanical technique ensures exact and dependable becoming.

Determine 5: Mechanical Shrinkage Instance 2

-The O-ring is now compressed and molded into the housing, creating a decent seal. The housing is particularly designed to accommodate the compressed O-ring. The supplies used for the housing and the O-ring are appropriate and designed for long-term efficiency. Be aware the particular materials and dimensions of the O-ring are essential for profitable mechanical shrinking.

Conclusive Ideas

In conclusion, shrinking an o-ring successfully requires an intensive understanding of the method, from materials choice to security measures. By following the steps Artikeld on this information, you may confidently shrink o-rings whereas minimizing dangers and maximizing effectivity. Keep in mind to prioritize security and search knowledgeable recommendation when wanted.

Prime FAQs

What are the widespread supplies used for O-rings?

Frequent O-ring supplies embrace nitrile rubber (NBR), neoprene, silicone, and Viton. The perfect materials alternative is determined by the particular software and working situations.

What are the potential hazards related to warmth shrinking?

Potential hazards embrace burns from excessive temperatures, materials degradation, and hearth if not dealt with fastidiously. All the time use applicable security tools.

How do I decide the right dimension for an O-ring?

Seek the advice of the producer’s specs or use a exact measuring software to find out the right dimension. Incorrect sizing can result in poor sealing and failure.

What are the emergency procedures in case of accidents?

Instantly cease the operation, comply with any emergency protocols, and phone emergency providers if wanted.