How you can deal with marine engine that wants leaded fuel is a vital information for boat house owners dealing with this distinctive scenario. This complete information delves into the specifics of dealing with leaded gasoline, from understanding its damaging results on engine parts to soundly transitioning to unleaded gas. Sustaining a wholesome engine is essential to preserving its lifespan and guaranteeing clean operation.

The intricate chemical make-up of leaded gasoline and its influence on marine engines is mentioned intimately. This features a detailed rationalization of the long-term penalties of utilizing leaded gas, reminiscent of harm to pistons, valves, and seals. Moreover, preventative upkeep steps, restore procedures, and the protected transition to unleaded gas are defined with clear directions and step-by-step guides.

Understanding Leaded Gasoline Impacts

Leaded gasoline, as soon as a ubiquitous gas supply, is now largely phased out as a result of its detrimental results on the surroundings and human well being. Nonetheless, understanding its historic position and the precise harm it induced to marine engines is essential for preventative upkeep and knowledgeable decision-making, particularly for these working with older vessels. This part delves into the composition, historic use, and long-term penalties of utilizing leaded gas in marine functions.

Chemical Composition and Results

Leaded gasoline accommodates tetraethyl lead (TEL) or different lead compounds. These components, whereas enhancing octane scores, introduce dangerous contaminants into the gas. The lead compounds, when burned, vaporize and type lead oxides. These lead compounds then deposit on engine parts, inflicting vital harm. The lead oxides, extremely corrosive, assault metallic surfaces, decreasing the lifespan of crucial engine elements.

The deposition of lead additionally alters the engine’s combustion effectivity, resulting in diminished energy output and elevated gas consumption.

Historic Context of Leaded Gasoline Utilization

Leaded gasoline was broadly utilized in marine engines for many years, primarily as a result of its greater octane ranking. This greater octane permitted greater compression ratios and engine efficiency. This attribute was notably useful for marine functions requiring sturdy energy output and engine reliability. This use was widespread in high-performance vessels and industrial marine engines, the place gas effectivity was not the first concern.

The available provide and perceived advantages contributed to its in depth use in numerous marine functions.

Lengthy-Time period Penalties on Engine Parts

The continual use of leaded gas in marine engines has extreme long-term penalties on numerous engine parts. The lead deposits corrode and put on down pistons, valves, and seals. This put on accelerates engine element failure, necessitating expensive repairs and replacements. The corrosive nature of lead compounds ends in untimely put on on bearings, impacting engine lubrication and additional decreasing operational lifespan.

This will result in expensive and frequent repairs, and finally, untimely engine failure.

Comparability of Leaded and Unleaded Fuels

| Attribute | Leaded Gasoline | Unleaded Gasoline |

|---|---|---|

| Chemical Composition | Accommodates tetraethyl lead (TEL) or different lead compounds. | Doesn’t comprise lead compounds. |

| Octane Score | Usually greater octane ranking. | Decrease octane ranking, although trendy unleaded formulations usually match or exceed leaded formulations in sensible phrases. |

| Engine Efficiency | Can ship greater energy output at greater RPMs. | Delivers constant and dependable efficiency, although could require completely different tuning. |

| Environmental Affect | Important environmental influence as a result of lead emissions. | Decrease environmental influence. |

| Engine Part Degradation | Accelerated put on and corrosion of engine elements as a result of lead deposits. | Slower put on and corrosion in comparison with leaded fuels. |

| Value | Traditionally decrease value in some areas. | Value is often comparable, and even decrease with trendy formulations. |

The desk above clearly highlights the important thing variations in chemical make-up and their subsequent results on engine efficiency and longevity. The shift to unleaded gas was pushed by environmental issues and the popularity of the dangerous long-term penalties of lead compounds on engines and the surroundings.

Figuring out Engine Injury Indicators

So, you have received a marine engine that is been operating on leaded gas. Now, what are the tell-tale indicators that one thing’s gone flawed? Realizing these early indicators is essential for stopping severe harm and dear repairs. Ignoring the warning indicators can result in extra in depth points and considerably greater restore payments down the street. Let’s dive into the signs and spot them.Engine efficiency points aren’t at all times apparent, however recognizing the signs of leaded gas harm can prevent lots of complications.

Early detection is essential, as small issues can shortly escalate into main malfunctions if left untreated. This information will equip you with the data to establish potential points and take the required preventative measures.

Signs of Leaded Gasoline Injury

Recognizing the signs of leaded gas harm is essential for well timed intervention. The signs can vary from refined efficiency modifications to extra pronounced mechanical points. Pay shut consideration to any modifications in your engine’s habits, as early detection can stop additional harm and dear repairs.

- Knocking or Pinging: A particular knocking or pinging sound, particularly throughout acceleration or below load, is a standard signal of detonation. Leaded gas, as a result of its distinctive composition, may cause untimely ignition, ensuing on this attribute noise. It is usually a precursor to extra extreme harm if not addressed promptly.

- Tough Operating: A tough or uneven engine operating, with an absence of clean operation, can level to points stemming from leaded gas. This erratic habits can point out a misfire or ignition issues straight associated to the gas’s properties.

- Poor Efficiency: Decreased energy output, slower acceleration, or issue in sustaining velocity are clear indicators of efficiency degradation. The engine’s energy and effectivity are diminished because of the gas’s influence on combustion and ignition processes.

- Elevated Emissions: A rise in smoke or uncommon smells, like a pungent or acrid odor, also can counsel points. The combustion course of is perhaps affected, resulting in improper burning of the gas and producing greater emissions. This might point out an issue inside the engine’s inner parts.

Potential Causes and Options

This desk Artikels potential causes for the aforementioned signs, with a concentrate on leaded gas points and acceptable options.

| Symptom | Doable Causes (together with leaded gas) | Options |

|---|---|---|

| Knocking/Pinging | Untimely ignition as a result of leaded gas composition, incorrect gas/air combination, broken spark plugs, worn engine parts | Examine and regulate gas/air combination, substitute spark plugs, examine and restore engine parts, think about using a special gas sort. |

| Tough Operating | Leaded gas contaminating the gas system, low compression, worn valves, broken pistons | Clear gas system, examine compression, restore valves and pistons, swap to a special gas sort. |

| Poor Efficiency | Leaded gas affecting combustion effectivity, clogged gas injectors, low oil stress, points with the ignition system | Clear gas injectors, test oil stress, examine the ignition system, swap to a special gas sort. |

| Elevated Emissions | Improper combustion as a result of leaded gas, malfunctioning exhaust system, points with engine parts | Examine and restore the exhaust system, examine engine parts for put on or harm, swap to a special gas sort. |

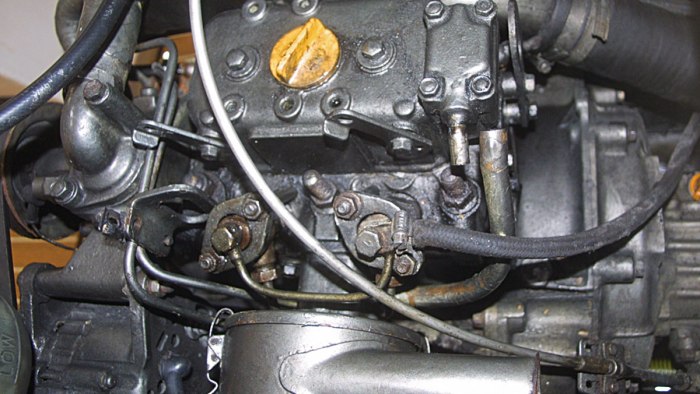

Visible Inspection for Injury

Visible inspection of engine parts is significant to establish potential harm from leaded gas. Search for any indicators of bizarre put on, corrosion, or deposits on the next:

- Cylinder Partitions: Examine for extreme put on or deposits on the cylinder partitions. Heavier deposits might point out vital harm from leaded gas.

- Pistons: Examine pistons for indicators of scoring, pitting, or uncommon put on patterns, which might level to leaded gas points.

- Valves: Study the valves for indicators of extreme put on, pitting, or deposits. Injury from improper combustion is perhaps seen.

- Gasoline System Parts: Examine gas injectors, gas traces, and filters for blockages or deposits, which may point out points with the gas supply system.

Significance of Early Detection

Addressing points associated to leaded gas early can stop a cascade of extra vital and dear issues. Immediate prognosis and restore reduce potential harm to important engine parts and keep away from in depth future repairs. Do not underestimate the worth of early detection.

Upkeep and Restore Procedures

Switching from leaded to unleaded gas is not only a easy gas swap; it is a vital change that calls for cautious consideration to your marine engine’s well being. Leaded gas’s corrosive nature and distinctive chemical composition can go away behind deposits that influence efficiency and longevity. Correct preventative upkeep and restore procedures are essential to mitigating harm and guaranteeing a clean transition.

This part dives deep into the required steps to keep up your engine’s well being and performance after utilizing leaded gas.The corrosive nature of leaded gas can result in vital inner harm if not addressed promptly. This harm manifests as deposits, corrosion, and potential mechanical failures. Implementing a sturdy upkeep schedule, notably when transitioning from leaded to unleaded gas, is significant to forestall long-term points and lengthen your engine’s lifespan.

Preventative Upkeep Steps

Common upkeep is essential to minimizing harm from leaded gas. A proactive strategy, relatively than a reactive one, is important to guard your funding. This contains meticulously checking gas traces, filters, and gas pumps for any indicators of injury or buildup. An intensive visible inspection can uncover points earlier than they escalate into expensive repairs. Additionally, frequently monitoring the engine’s efficiency indicators, reminiscent of oil stress and coolant temperature, offers helpful insights into potential issues.

Early detection of points usually interprets to extra manageable repairs and fewer downtime.

Common Engine Flushing and Cleansing

Switching from leaded to unleaded gas requires a radical engine flushing course of. This step is crucial to take away the remaining leaded gas residue that may trigger corrosion and harm. The deposits left behind can hinder the engine’s efficiency, resulting in potential breakdowns. A correct flush cleans out the gas system, guaranteeing that unleaded gas can circulate freely and effectively.

The absence of leaded gas deposits within the system helps the engine function extra easily and effectively.

Particular Procedures for Changing Broken Parts

Changing broken parts is a vital facet of sustaining engine well being. This usually entails disassembling affected sections, cleansing them completely, and putting in new elements. It is vital to make sure all parts are appropriate with the precise engine mannequin. The alternative course of ought to comply with the producer’s tips to keep up the engine’s optimum efficiency and longevity. Correctly documented procedures and detailed schematics can support in correct element alternative.

Step-by-Step Information to Engine Flushing and Cleansing

A scientific strategy to engine flushing is crucial for efficient elimination of leaded gas residues.

- Drain the Gasoline System: Empty the gas tank and disconnect the gas traces. Rigorously drain any remaining gas from the gas traces and filter.

- Put together the Flushing Answer: Use a specialised gas system cleaner particularly designed for marine engines. Comply with the producer’s directions for dilution ratio.

- Flush the Gasoline System: Slowly introduce the flushing answer into the gas system, guaranteeing all parts are saturated. Enable the answer to flow into by the system for the beneficial time, usually indicated by the cleaner’s directions. Monitoring the answer’s effectiveness is vital to find out if a second flush is required.

- Drain the Flushing Answer: As soon as the flushing is full, drain the answer from the gas tank and all related traces.

- Examine and Change Parts: Rigorously examine all parts of the gas system for harm. Change any broken elements, together with gas filters and gas pumps. Completely clear all parts and test for particles or blockages.

- Reassemble the Gasoline System: Rigorously reassemble the gas system, guaranteeing all connections are safe and tight. Double-check the gas traces and connections to forestall leaks.

- Fill with Unleaded Gasoline: Fill the gas tank with contemporary unleaded gas and begin the engine. Monitor the engine’s efficiency and pay attention for any uncommon noises or leaks.

Instruments and Supplies Required

The next instruments and supplies are important for the upkeep and restore procedures:

| Class | Objects |

|---|---|

| Instruments | Wrench units, screwdrivers, pliers, gas line wrenches, drain pan, funnel, rags, cleansing brushes |

| Supplies | Gasoline system cleaner, contemporary unleaded gas, alternative elements (as wanted), security glasses, gloves, protecting clothes |

Correct upkeep procedures reduce the chance of leaded gas harm and make sure the longevity of your marine engine.

Transitioning to Unleaded Gasoline

Switching from leaded to unleaded gas in your marine engine is a big step that requires cautious planning and execution. It is not only a easy swap; it impacts the engine’s efficiency and longevity. Ignoring correct procedures can result in expensive repairs and diminished engine life. This information offers a complete roadmap for a clean transition.

Preparation for the Gasoline Change

Correct preparation is essential for a profitable transition. This entails extra than simply filling the tank with unleaded gas. An intensive inspection of the whole gas system is important. Search for any indicators of wear and tear, corrosion, or harm that may have been exacerbated by leaded gas. Cleanliness is paramount; make sure the gas traces and parts are freed from any residue.

Gasoline System Cleansing

Thorough cleansing of the gas system is significant earlier than introducing unleaded gas. Leaded gas can go away deposits within the gas tank, traces, and carburetor. These deposits can hinder the graceful circulate of unleaded gas, doubtlessly resulting in engine points. Skilled cleansing companies can be found and could be useful, particularly for complicated gas techniques.

Engine Modifications (if wanted), How you can deal with marine engine that wants leaded fuel

Whereas many trendy marine engines are designed to run on unleaded gas, some older fashions may require modifications. These modifications usually middle across the engine’s gas supply system, such because the carburetor or gas injectors. A professional mechanic ought to assess the engine’s particular wants. Some changes could also be so simple as changing gas filters, whereas others may contain extra in depth modifications.

Seek the advice of your engine’s producer specs for steering.

Efficiency Comparability: Leaded vs. Unleaded

Leaded gas, whereas as soon as widespread, provides inferior efficiency in comparison with unleaded gas in trendy engines. Leaded gas’s components, designed to boost combustion, can go away deposits and doubtlessly trigger put on in engine parts. Unleaded gas, designed for cleaner combustion, usually ends in smoother operation and prolonged engine life. Trendy unleaded gas formulations are particularly designed to keep up optimum efficiency in trendy engines.

Transition Steps, Potential Points, and Options

| Step | Potential Points | Options |

|---|---|---|

| 1. Drain the present leaded gas tank utterly. | Incomplete draining can go away residual leaded gas. | Use a gas drain pump or a gas switch system to make sure full elimination. |

| 2. Completely clear the gas tank and features. | Dust, particles, or leaded gas deposits can hinder correct operation. | Use acceptable cleansing brokers and instruments to take away all residues. |

| 3. Set up new gas filters. | Outdated filters could comprise leaded gas deposits, hindering gas circulate. | Change gas filters with new, unleaded fuel-compatible filters. |

| 4. Fill the tank with unleaded gas. | Improper gas high quality may cause engine issues. | Make sure you use high-quality unleaded marine gas and test for any contaminants. |

| 5. Begin the engine and monitor its operation. | Potential points like sputtering, misfiring, or tough idling can happen. | Determine the problem and tackle it by adjusting gas supply, air consumption, or ignition. |

Lengthy-Time period Engine Well being Concerns: How To Deal with Marine Engine That Wants Leaded Gasoline

Operating a marine engine on leaded gas, whereas maybe needed in sure conditions, has vital long-term penalties for engine well being and longevity. Understanding these implications is essential for making knowledgeable selections about your vessel’s future. Ignoring the detrimental results of leaded gas can result in expensive repairs and diminished total efficiency, impacting your boating expertise.Leaded gasoline, regardless of its historic use, is understood to speed up the deterioration of engine parts over time.

The lead deposits, whereas seemingly minor, can accumulate and create severe points if not addressed promptly. This accumulation straight impacts the engine’s effectivity, reliability, and finally, its lifespan. The corrosive nature of leaded gas may cause vital harm, and correct upkeep methods turn out to be much more crucial when coping with engines uncovered to leaded gas.

Lengthy-Time period Implications of Leaded Gasoline

The long-term implications of utilizing leaded gas lengthen past quick efficiency points. The presence of lead within the gas system considerably accelerates the wear and tear and tear on engine parts. This impact could be notably pronounced within the combustion chamber, valves, and pistons, resulting in untimely failure and better upkeep prices. Over time, lead buildup in these areas can hinder correct sealing and lubrication, decreasing total effectivity and doubtlessly inflicting catastrophic engine failure.

Results on Engine Lifespan and Efficiency

Leaded gas drastically reduces the lifespan of marine engines. The corrosive nature of lead compounds assaults the metallic parts, accelerating rust, erosion, and put on. This accelerated deterioration can manifest in quite a lot of methods, from diminished energy output to finish engine failure. The elevated frequency of repairs and replacements will considerably shorten the general lifespan of the engine.

For instance, a marine engine operating on leaded gas may require main overhaul inside 5-10 years, whereas an engine operating on unleaded gas might final 15-20 years with correct upkeep. Efficiency degradation is one other vital situation. Engines operating on leaded gas could expertise decreased horsepower, diminished gas effectivity, and elevated emissions.

Methods to Maximize Longevity After Leaded Gasoline Use

Thorough cleansing and upkeep are important after utilizing leaded gas. This features a full gas system flush to take away any remaining lead deposits. Changing crucial parts, reminiscent of spark plugs, gas injectors, and filters, can also be extremely beneficial to mitigate the harm brought on by lead buildup. Think about using specialised cleansing brokers designed for leaded gas residue to make sure complete elimination.

Common inspections and upkeep are essential to establish any creating points early on, doubtlessly stopping catastrophic failures.

Environmental Considerations

Using leaded gas in marine functions raises vital environmental issues. Lead emissions contribute to air air pollution, impacting each human well being and the marine ecosystem. Leaded gas also can contaminate water sources, posing a risk to aquatic life. This can be a crucial facet to think about, particularly when working in environmentally delicate areas.

Affect of Leaded Gasoline Use on Engine Parts

| Engine Part | Affect of Leaded Gasoline (Over Time) |

|---|---|

| Pistons | Elevated put on and tear, potential scoring, and diminished compression. |

| Valves | Corrosion, sticking, and potential valve seat harm. |

| Cylinders | Lead deposits and erosion, doubtlessly resulting in uneven put on. |

| Gasoline injectors | Clogged injectors and diminished gas atomization, resulting in poor combustion. |

| Gasoline traces | Corrosion and potential leaks, affecting gas supply and engine efficiency. |

| Crankshaft | Elevated put on and tear, potential seizing, and diminished lubrication. |

Security Precautions

Sustaining a marine engine, particularly one accustomed to leaded gas, requires meticulous consideration to security. Leaded gas residue and doubtlessly broken engine parts current vital hazards. Ignoring these precautions can result in extreme accidents and dear repairs. Proactive security measures are essential for each the technician and the surroundings.

Potential Hazards of Working with Leaded Gasoline

Leaded gasoline poses a number of security dangers. The lead itself is very poisonous, and extended publicity may cause severe well being points. Furthermore, contaminated engine elements, reminiscent of pistons and cylinders, can launch lead mud throughout dealing with. The presence of leaded gas residue also can create hearth hazards, particularly when mixed with sparks or warmth. Improper dealing with can result in vital dangers.

Working with these supplies calls for excessive warning.

Security Tips for Dealing with Leaded Gasoline and Contaminated Elements

When working with leaded gas or contaminated engine elements, at all times put on acceptable private protecting tools (PPE). This features a respirator, security glasses, gloves, and a full-body coverall. At all times guarantee the realm is well-ventilated. By no means smoke or use open flames within the neighborhood of leaded gas or contaminated elements. Dealing with these supplies calls for a scientific and cautious strategy to keep away from potential accidents.

Correct Air flow and PPE

Enough air flow is paramount when working with leaded gas. Use exhaust followers or different air flow techniques to take away fumes from the work space. Using a respirator is crucial for stopping lead inhalation. Select an acceptable respirator primarily based on the extent of lead publicity. A correctly fitted respirator can present vital safety towards lead mud and fumes.

This safeguards the technician from potential long-term well being points.

Security Guidelines for Upkeep and Restore

An intensive security guidelines ought to be applied earlier than any upkeep or restore procedures. This guidelines ought to embrace:

- Affirm correct air flow is in place.

- Confirm all needed PPE is on the market and in good situation.

- Make sure the work space is free from any potential hearth hazards.

- Correctly label and retailer all leaded gas and contaminated engine fluids.

- Implement strict procedures for dealing with and disposing of leaded gas and contaminated elements.

This guidelines is a vital first step in establishing a protected work surroundings.

Correct Disposal Strategies for Leaded Gasoline and Contaminated Fluids

Correct disposal of leaded gas and contaminated engine fluids is crucial. By no means pour these supplies down drains or into the surroundings. Contact native environmental authorities or hazardous waste disposal corporations to find out the suitable disposal strategies. Laws range by area. Seek the advice of with native authorities to make sure compliance with environmental laws.

That is important for stopping environmental contamination.

Closing Abstract

In conclusion, this information offers a radical understanding of treating marine engines needing leaded fuel. From figuring out potential harm to transitioning to unleaded gas, this information equips boat house owners with the data to keep up their engines successfully. By following the supplied steps, boat house owners can stop additional deterioration, lengthen engine lifespan, and guarantee protected operation. Keep in mind, security is paramount, so strictly adhere to the security precautions Artikeld on this information.

FAQ Part

What are the early warning indicators of leaded gas harm in a marine engine?

Early indicators can embrace knocking sounds, tough operating, and poor efficiency. A visible inspection of engine parts can reveal additional harm. Seek the advice of the desk of signs and causes in the principle information for extra particulars.

What are the potential environmental issues associated to utilizing leaded gas in marine functions?

Leaded gas can have detrimental environmental impacts. Correct disposal strategies for leaded gas and contaminated fluids are important. Seek the advice of the security precautions part for extra info.

What instruments and supplies are wanted for engine flushing and cleansing after utilizing leaded gas?

The precise instruments and supplies required will rely upon the extent of the harm and the engine sort. Consult with the upkeep and restore procedures part for an in depth listing.