use trailer brake controller is essential for protected and environment friendly towing. This information gives a complete overview of the subject, masking every part from controller varieties and elements to set up, operation, troubleshooting, upkeep, and security concerns. Understanding the right way to use your trailer brake controller successfully can stop accidents and guarantee a clean and satisfying towing expertise.

Trailer brake controllers are important security units for any car towing a trailer. They regulate the braking energy utilized to the trailer, making certain coordinated braking between the towing car and the trailer. Correct use of the controller is important for sustaining management and avoiding potential hazards, particularly when touring on totally different terrains or going through sudden conditions.

Introduction to Trailer Brake Controllers

Trailer brake controllers are important elements of towing programs, enabling protected and managed braking of trailers. They act as an middleman between the towing car’s braking system and the trailer’s brakes, making certain the trailer’s deceleration mirrors that of the towing car. That is essential for sustaining management and stopping accidents, particularly at increased speeds or throughout emergency conditions.Trailer brake controllers present a vital hyperlink between the braking programs of the towing car and the trailer, permitting for coordinated deceleration.

With out them, the trailer’s brakes may not reply successfully or in any respect to the towing car’s braking enter, resulting in probably harmful conditions.

Kinds of Trailer Brake Controllers

Various kinds of trailer brake controllers cater to varied towing wants and car configurations. Understanding these distinctions is essential to choosing the suitable controller.

- Electrical Brake Controllers:

- These controllers use electrical indicators to activate the trailer’s brakes. They’re the commonest kind, providing a responsive and dependable braking efficiency. The controller’s sensitivity determines the braking drive utilized to the trailer. {The electrical} indicators are transmitted from the towing car’s brake pedal to the trailer’s brakes.

- Pneumatic Brake Controllers:

- These controllers make the most of air strain to activate the trailer’s brakes. Whereas much less frequent, they’re typically used for bigger trailers or in specialised purposes. Pneumatic programs supply a strong braking system, however they require devoted air traces between the towing car and the trailer.

Significance of Utilizing a Trailer Brake Controller, use trailer brake controller

Utilizing a trailer brake controller is paramount for security throughout towing. With out a controller, the trailer’s brakes may not reply successfully, inflicting the trailer to brake slower than the towing car, or under no circumstances. This can lead to a lack of management and probably harmful conditions. For instance, if a car is approaching a cease signal and the trailer brakes do not have interaction correctly, the trailer may run into the car and even jackknife, making a hazardous state of affairs.

Comparability of Brake Controller Varieties

| Kind | Professionals | Cons | Appropriate for |

|---|---|---|---|

| Electrical | Dependable, responsive, comparatively cheap, straightforward to put in. | Efficiency can fluctuate primarily based on the controller’s sensitivity settings. | Most passenger autos towing smaller trailers. |

| Pneumatic | Strong braking, appropriate for heavy-duty purposes. | Extra advanced to put in, requires air traces, and will be costlier. | Giant trailers, heavy hundreds, or specialised purposes requiring excessive braking energy. |

Understanding the Parts

Trailer brake controllers are subtle programs that translate driver enter into exact braking drive for the trailer. Understanding their elements is essential for correct operation and protected towing. A well-maintained and understood system contributes to a extra environment friendly and managed braking course of.A typical trailer brake controller consists of a number of interconnected components that work in live performance to offer proportional braking drive to the trailer brakes.

Every part performs a selected position within the general system, from sensing driver enter to actuating the trailer brakes. These elements are designed to be dependable and sturdy, however common inspection and upkeep can prolong their lifespan and guarantee correct perform.

Key Parts and Their Features

The core elements of a trailer brake controller system, from driver enter to the trailer’s braking motion, usually embrace a management module, a sensor, and an actuator. These parts work collectively to regulate braking drive in response to the motive force’s actions. Understanding their particular person roles is crucial for recognizing points and sustaining the system.

Management Module

The management module is the central processing unit of the trailer brake controller. It receives indicators from the sensor, processes this knowledge, and sends indicators to the actuator to control the quantity of air strain or electrical present despatched to the trailer brakes. This permits for proportional braking management, that means the controller adjusts the braking drive primarily based on the motive force’s braking enter.

It is a essential part for making certain the trailer brakes reply appropriately to the motive force’s instructions.

Sensor

The sensor, usually a strain sensor in air brake programs or a potentiometer in electrical programs, displays the motive force’s braking enter. It measures the diploma of driver brake pedal utility. This measurement is translated right into a sign that the management module makes use of to control the output to the actuator. Correct sensing of driver enter is important for applicable braking drive utility.

Actuator

The actuator is the ultimate part within the chain. It is chargeable for adjusting the air strain (in air brake programs) or electrical present (in electrical programs) to the trailer brakes. This adjustment is exactly primarily based on the sign from the management module, permitting for a proportional response to the motive force’s braking enter. The actuator’s perform straight impacts the effectiveness of the trailer braking system.

Hydraulic/Electrical System Diagram

(Illustrative diagram can be positioned right here, if attainable, however isn’t created by this AI mannequin)Think about a simplified hydraulic system. The motive force’s brake pedal enter is sensed by a strain sensor. This sign is processed by the management module, which then regulates the air strain output to the trailer brakes. This managed strain change applies the brakes on the trailer proportionally to the motive force’s enter.

Element Desk

| Element | Operate | Location |

|---|---|---|

| Management Module | Processes driver enter and regulates air strain/electrical present to the trailer brakes. | Usually throughout the brake controller unit, mounted on the car. |

| Sensor | Measures the motive force’s braking enter. | Built-in with the brake pedal system or mounted on the management module. |

| Actuator | Adjusts the air strain or electrical present to the trailer brakes. | Related to the trailer brake system, both straight or by means of a valve. |

Set up Procedures

Correct set up of a trailer brake controller is essential for protected and efficient trailer braking. Incorrect set up can result in malfunctioning brakes, decreased braking effectivity, and potential security hazards. Adhering to the producer’s directions and security precautions is paramount. This part particulars the set up course of, highlighting vital concerns for numerous car varieties.

Security Precautions

Prioritizing security is paramount throughout set up. Disconnect the car’s battery earlier than beginning any work. Guarantee sufficient lighting and a transparent workspace to forestall accidents. Put on applicable security glasses and gloves to guard your self from particles and potential hazards. Seek the advice of your car’s proprietor’s guide for particular security procedures and warnings.

Instruments Required

A complete record of instruments will streamline the set up course of. This can embrace a screwdriver set (Phillips and flathead), a wire strippers/crimpers, a wrench set (applicable for the car’s particular {hardware}), a multimeter (for electrical checks), and any specialised instruments really helpful by the trailer brake controller producer. Further instruments could also be required relying on the precise car kind and controller mannequin.

Set up Strategies for Completely different Car Varieties

Set up strategies fluctuate barely relying on the car kind. Truck installations typically require entry to the car’s wiring harness and a correct mounting location. RV installations could contain connecting to the prevailing RV electrical system. The precise steps for every car kind are Artikeld within the respective set up manuals. Fastidiously assessment the controller’s set up information and your car’s proprietor’s guide for detailed directions.

Step-by-Step Set up Process (Normal Pointers)

- Find the suitable mounting place for the controller. Seek advice from the controller’s instruction guide for particular mounting suggestions.

- Put together the mounting location by cleansing and making certain a safe floor.

- Set up the controller in line with the supplied directions. Securely connect the controller utilizing the supplied {hardware}.

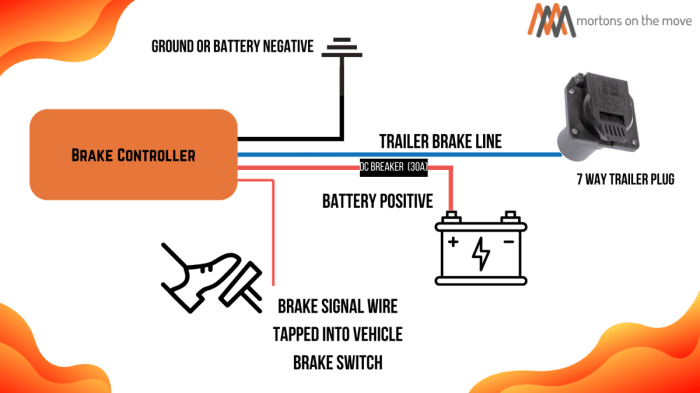

- Join the controller’s wiring to the car’s electrical system. Comply with the controller’s wiring diagram rigorously. Crimp and seal all connections to forestall brief circuits or electrical issues.

- Take a look at the performance of the trailer brake controller by making use of the brakes and checking the trailer’s brakes have interaction. Modify settings as wanted.

- Confirm all connections are safe and correctly terminated. Verify for any potential points like unfastened wires or uncovered terminals. Recheck the whole system for security.

- Reconnect the car’s battery and carry out a radical useful take a look at of the trailer brake system. Take a look at braking at numerous speeds to make sure correct performance.

Set up Move Chart (Simplified)

This simplified flowchart illustrates the overall set up course of. Every step needs to be meticulously adopted for correct set up.

Troubleshooting

If points come up through the set up course of, discuss with the troubleshooting part of the trailer brake controller’s guide. Widespread issues embrace incorrect wiring connections, defective elements, or improper settings.

Primary Operation

Correct operation of a trailer brake controller is essential for protected towing. This part particulars the important steps for connecting, adjusting, testing, and working the controller for numerous terrain circumstances. Right operation minimizes the chance of accidents and ensures clean and managed braking.

Connecting the Trailer to the Car’s Braking System

The trailer’s braking system should be appropriately linked to the car’s braking system. Incorrect wiring can result in inoperable brakes and even injury to elements. A correct connection is a basic facet of protected towing. Seek the advice of the car and trailer manuals for particular wiring diagrams and procedures. Guarantee all connections are safe and correctly grounded.

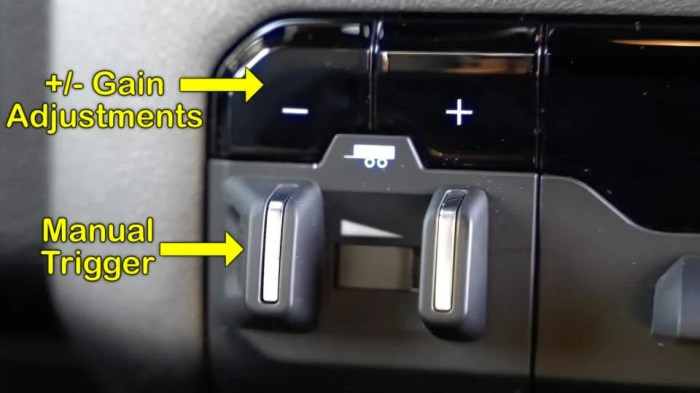

Adjusting Controller Settings for Correct Braking

Exact adjustment of the controller settings is important for efficient braking. The controller usually has adjustable parameters for sensitivity and braking drive. These settings have to be tailor-made to the precise weight and sort of trailer being towed. Over-adjusting can result in extreme braking, whereas under-adjusting could not present adequate braking drive. Testing and fine-tuning the settings in numerous eventualities is really helpful.

Testing the Trailer Brakes

Thorough testing of the trailer brakes is crucial for verifying their performance. Start with the car’s engine off and the parking brake engaged. Apply the service brakes on the car after which the trailer brake controller. The trailer brakes ought to have interaction easily and proportionately to the car’s braking enter. If the trailer brakes don’t have interaction or reply inconsistently, seek the advice of the controller and trailer manuals to troubleshoot the problem.

Evaluating Braking Strategies for Numerous Terrain Situations

Completely different terrain circumstances require totally different braking approaches. On dry, paved roads, a reasonable braking strain is usually adequate. Nevertheless, on slippery surfaces like ice or snow, decreased braking strain is essential to forestall skidding. A managed, gradual braking method is usually really helpful for all conditions. Keep away from sudden or forceful braking, which may result in lack of management.

Step-by-Step Information to Working the Controller in Completely different Situations

A scientific method to working the controller in numerous conditions is crucial. This contains understanding the controller’s response to totally different braking inputs.

- Situation 1: Stage Highway, Dry Situations: Apply mild braking strain on the car’s brakes. The controller will modify the trailer brakes proportionally. Observe the trailer’s response to take care of management.

- Situation 2: Hill Descent: Scale back the car’s pace progressively earlier than beginning the descent. Preserve a gentle braking strain to forestall extreme deceleration. Use decrease gears to assist management the car’s pace and the trailer’s braking.

- Situation 3: Slippery Highway Situations: Apply considerably much less braking strain than regular. Keep away from sudden stops or arduous braking. Modify the controller’s sensitivity settings to reduce braking drive.

- Situation 4: Stopping on a Hill: Apply the parking brake on the car earlier than participating the trailer brakes. Preserve constant braking strain and make sure the car stays stationary.

Troubleshooting Widespread Points

Correctly diagnosing and resolving points with a trailer brake controller is essential for protected and environment friendly towing. Ignoring issues can result in security hazards and probably injury to the trailer or tow car. This part particulars frequent issues, their causes, and the steps to diagnose and repair them.Efficient troubleshooting entails systematically figuring out the supply of the issue. This requires understanding the elements and their interactions, together with recognizing the warning indicators the system gives.

Thorough examination and methodical testing will assist in isolating the trigger and implementing the suitable answer.

Figuring out Issues with Trailer Brake Controller Operation

Widespread issues with trailer brake controllers embrace inconsistent braking, no braking, erratic braking, and warning lights. Understanding the precise situation is step one to find an answer.

Diagnosing No Braking

This situation can stem from a number of components. First, verify {the electrical} connections between the tow car and the trailer brake controller. Guarantee all connections are clear and tight. Subsequent, confirm the trailer brake controller is correctly put in and functioning. Examine the fuse and relays associated to the trailer brake controller circuit in each the tow car and the trailer.

If all connections are right and the fuses/relays are intact, the issue would possibly lie with the trailer brakes themselves. A defective trailer brake system, corresponding to a malfunctioning brake actuator or a brake line situation, must be investigated.

Diagnosing Inconsistent or Erratic Braking

Inconsistent or erratic braking typically signifies an issue with the trailer brake controller’s operation or a malfunction within the trailer’s braking system. Step one in troubleshooting entails checking for unfastened or corroded wiring connections. Examine the brake controller’s inside elements for injury. If the controller appears to be functioning appropriately, verify for injury or put on on the trailer’s brake traces or elements.

This would possibly contain inspecting the brake footwear and pads for put on, and making certain the brake actuator operates appropriately.

Deciphering Warning Lights and Indicators

Completely different trailer brake controllers use numerous warning lights to point potential points. Seek the advice of the proprietor’s guide for particular interpretations. Widespread warning lights would possibly signify low battery voltage, defective brake controller operation, or points with the trailer brake system. These lights are essential diagnostic instruments and supply crucial info for figuring out the character of the issue.

Troubleshooting Ideas for Particular Conditions

When troubleshooting, systematically checking the next may also help:

- Confirm that the trailer brakes are engaged when the tow car brakes are utilized.

- Verify the voltage on the trailer brake controller to make sure {the electrical} system is functioning appropriately.

- Examine the trailer brake controller’s wiring harness for any injury or corrosion.

Desk of Widespread Trailer Brake Controller Issues

| Downside | Trigger | Resolution |

|---|---|---|

| No trailer braking | Defective connections, blown fuse, malfunctioning trailer brakes | Verify wiring connections, substitute fuse, examine trailer brakes |

| Inconsistent or erratic braking | Unfastened wiring, broken controller, malfunctioning trailer brakes | Tighten wiring, examine controller, verify trailer brakes |

| Warning lights illuminated | Low battery voltage, defective controller, wiring points | Verify battery voltage, examine controller, look at wiring |

| Weak or no response to brake controller changes | Low battery, defective controller, defective trailer brakes | Verify battery, examine controller, verify trailer brakes |

Upkeep and Care

Correct upkeep of a trailer brake controller is essential for its longevity and dependable operation. Common checks and servicing make sure the controller features as supposed, stopping potential accidents and expensive repairs. Neglecting upkeep can result in untimely failure, probably compromising the protection of each the car and the trailer.Sustaining a trailer brake controller entails a variety of procedures, from visible inspections to part replacements.

Constant adherence to a upkeep schedule is crucial to forestall sudden breakdowns and preserve optimum efficiency.

Common Inspections

Common inspections are very important for early detection of potential issues. Visible inspections can reveal points like corrosion, unfastened connections, or broken elements, permitting for well timed intervention. These inspections ought to embrace checking for any indicators of fluid leaks, broken wiring, or uncommon noises. Immediate consideration to those points can stop escalating issues.

Advisable Upkeep Procedures

A complete upkeep schedule ensures the controller’s optimum efficiency and extends its lifespan. The next procedures are really helpful:

- Visually examine all wiring connections for tightness and indicators of harm. Look at for any indicators of corrosion or fraying.

- Verify the controller’s mounting for any looseness or injury. Guarantee safe attachment to forestall vibration-related points.

- Examine the air strain gauges or hydraulic fluid ranges (if relevant) for correct readings. Make sure the system is working throughout the producer’s specs.

- Clear the controller’s housing and elements utilizing a mushy fabric and delicate detergent. Keep away from harsh chemical substances that might injury the controller’s casing or inside elements.

- Totally verify the brake traces for any cracks, leaks, or indicators of harm. Leaks can result in decreased braking effectivity.

Changing Worn Elements or Parts

Changing worn or broken elements is essential for sustaining the controller’s effectivity and security.

- Examine the controller’s elements for put on and tear. This contains the sensors, actuators, and every other transferring components.

- Seek the advice of the producer’s suggestions for substitute components. Utilizing the proper components ensures correct perform and compatibility with the controller mannequin.

- Comply with the producer’s directions rigorously when changing components. Incorrect set up can result in malfunctions or security hazards.

- Be sure that all connections are safe and correctly tightened to forestall electrical points or leaks.

Frequency of Upkeep Checks

Common upkeep intervals are very important for stopping points and sustaining peak efficiency.

- Month-to-month: Conduct a visible inspection of all elements, together with wiring, connections, and mounting. Verify for any indicators of harm or put on.

- Quarterly: Clear the controller housing and examine for corrosion. Verify the air strain (or hydraulic fluid) and brake traces for leaks or injury.

- Yearly: Carry out a complete inspection of all elements, together with changing worn components as vital. Have the controller inspected by a certified technician for a radical analysis.

Security Concerns

Protected trailer operation is paramount to forestall accidents and accidents. Correct use of a trailer brake controller, mixed with protected driving practices, considerably reduces the chance of incidents. Understanding the components influencing braking efficiency and adhering to security pointers for numerous trailer varieties is essential for accountable towing.Protected trailer operation requires proactive measures, extending past simply the controller itself.

A radical understanding of how trailer brakes perform along side the car’s braking system and consciousness of potential hazards is crucial. This contains recognizing and mitigating components that might compromise braking efficiency.

Significance of Protected Braking Procedures

Protected braking procedures are crucial for sustaining management and stopping accidents. Constant and predictable braking is crucial for avoiding sudden stops or uncontrolled maneuvers. Constant brake utility prevents the trailer from swaying or jackknifing, particularly at excessive speeds or throughout sudden braking.

- Anticipate braking conditions: Precisely predicting braking wants, corresponding to when approaching intersections or slowing down for obstacles, permits for proactive braking changes. Anticipatory braking avoids sudden or forceful braking maneuvers, which may destabilize the trailer. This contains accounting for modifications in highway circumstances, climate, and site visitors circulation.

- Preserve a protected following distance: Adequate following distance permits for ample response time in case of sudden braking. An extended distance between autos provides extra time to regulate the trailer’s pace, particularly in conditions involving downhill braking or heavy hundreds. A basic rule is to take care of a following distance that permits for 3 to 4 seconds between your car and the car in entrance.

- Keep away from aggressive braking: Aggressive braking could cause the trailer to sway or skid. Gradual and managed braking prevents sudden deceleration, making certain the trailer maintains stability.

Elements Affecting Braking Efficiency

A number of components can affect the effectiveness of trailer braking. Understanding these components permits for proactive changes to make sure protected operation.

- Trailer weight and cargo distribution: The load of the trailer and its load straight impression the braking distance. Imbalance in load distribution could cause the trailer to sway or skid throughout braking. Heavy hundreds require extra constant braking effort.

- Highway circumstances: Moist, icy, or uneven surfaces have an effect on braking effectivity. Braking distances improve on slippery surfaces, demanding elevated warning and decreased pace. The kind of highway floor needs to be considered for braking.

- Velocity: Larger speeds require longer braking distances. A better distance is required to decelerate from a better pace, requiring extra constant and proactive braking changes.

Significance of Common Inspections

Common inspections are very important for making certain the protection and reliability of the trailer brake system. A well-maintained system is extra more likely to carry out as anticipated and forestall sudden failures throughout operation.

- Visible inspection: Usually verify the trailer’s braking elements, together with brake traces, hoses, and wheel bearings. Search for any indicators of damage, injury, or leaks. Visible inspection ought to embrace checking the brake pads and rotors for put on and tear. The inspection needs to be complete, together with the whole braking system.

- Brake testing: Carry out periodic brake assessments to verify the system’s performance. Testing ought to embrace checking for correct activation of the trailer brakes when the car’s brakes are utilized. This may be performed by stopping the car and trailer in a protected space to verify the trailer’s brake response.

Security Pointers for Towing Completely different Trailer Varieties

Security pointers fluctuate relying on the kind of trailer being towed. Consciousness of particular security measures is essential for accountable towing.

- Flatbed trailers: Flatbed trailers are sometimes used for heavy hundreds, requiring cautious consideration to load distribution. Load securing is crucial to forestall shifting and swaying throughout braking. This contains correct anchoring and securing the load.

- Fifth-wheel trailers: Fifth-wheel trailers have particular coupling and braking necessities. Adherence to producer’s directions for coupling and braking is crucial. It’s crucial to observe the producer’s suggestions for protected coupling and uncoupling procedures.

- Journey trailers: Journey trailers typically carry passengers and belongings. Guaranteeing sufficient braking response and applicable load distribution is crucial. Applicable pace and following distance needs to be maintained when towing a journey trailer.

Closure

This information has completely lined the essential features of trailer brake controller operation. By understanding the different sorts, elements, set up procedures, and operational strategies, you’ll be able to successfully use your trailer brake controller for protected and assured towing. Keep in mind to prioritize security, recurrently preserve your system, and deal with any points promptly. Joyful towing!

FAQ Nook: How To Use Trailer Brake Controller

What are the various kinds of trailer brake controllers?

Trailer brake controllers are available in electrical and pneumatic varieties. Electrical controllers use electrical indicators to manage the trailer brakes, whereas pneumatic controllers use air strain. Electrical controllers are extra frequent and customarily simpler to put in and use.

How do I do know if my trailer brake controller is working correctly?

A easy take a look at is to use the brakes on the towing car. The trailer brakes ought to have interaction concurrently. If not, verify the connections and settings. If the problem persists, seek the advice of a mechanic or the producer’s guide.

What ought to I do if my trailer brakes should not working?

First, verify the ability provide to the trailer brakes. If there isn’t a energy, then there’s a downside with {the electrical} connections. If there may be energy, then verify the brake controller settings. If the problem persists, seek the advice of knowledgeable mechanic.

What are the commonest causes of trailer brake controller malfunctions?

Defective wiring, broken elements throughout the controller, and improper set up are frequent causes. Checking for unfastened connections, broken wires, and making certain correct set up may also help stop malfunctions.