Tips on how to wire a trailer with trailer brakes? This complete information will stroll you thru the important steps, from understanding the significance of correct wiring and braking methods to troubleshooting widespread points. We’ll cowl numerous trailer wiring methods, security precautions, and various kinds of trailer brakes. Prepare to overcome the duty of connecting your trailer to your tow automobile safely and successfully.

Mastering trailer wiring is essential for secure towing. Correctly wired brakes guarantee your trailer responds successfully to your automobile’s braking system, minimizing the chance of accidents. This information will present clear, step-by-step directions, together with useful visuals the place relevant, that will help you set up and keep your trailer’s electrical system.

Introduction to Trailer Wiring and Brakes

Correct trailer wiring and braking methods are essential for secure and authorized towing. A well-maintained and accurately wired trailer system enhances driver visibility, reduces the chance of accidents, and ensures compliance with site visitors rules. With out correct functioning brakes, a trailer can change into uncontrollable, posing a major hazard to each the towing automobile and different street customers.The potential penalties of improper wiring or malfunctioning trailer brakes are substantial.

Defective wiring can result in electrical malfunctions, probably inflicting fires, and even electrical shock. Malfunctioning brakes can lead to a lack of management, resulting in collisions, accidents, and important property harm. Understanding and sustaining these methods is significant for the protection of everybody on the street.

Significance of Correct Trailer Wiring

Trailer wiring methods transmit essential alerts between the towing automobile and the trailer, controlling lights and brakes. This permits different drivers to see the trailer and ensures that the trailer’s braking system is activated when the towing automobile’s brakes are engaged. Appropriately functioning wiring is important for sustaining visibility and stopping accidents.

Kinds of Trailer Wiring Programs

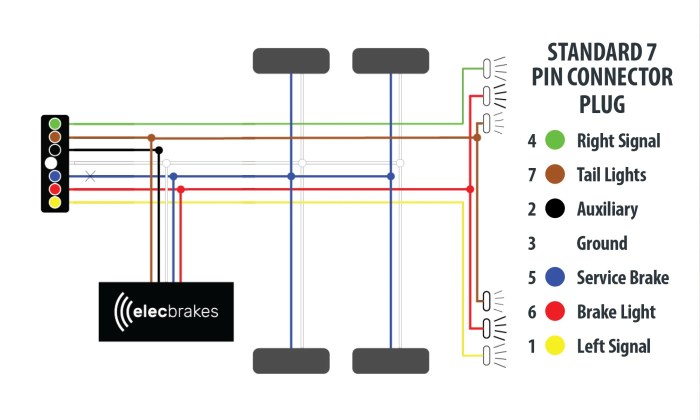

Numerous trailer wiring methods exist, every designed for various trailer varieties and options. The commonest varieties embody 7-way and 4-way connectors. A 7-way connector is often used for heavier trailers, together with these with a number of lights and brake methods. A 4-way connector is extra widespread for smaller trailers that don’t require the extra performance of the 7-way connector.

Security Precautions Earlier than Engaged on Electrical Programs

Earlier than engaged on any electrical system, together with trailer wiring, essential security precautions have to be noticed. First, make sure the automobile’s ignition is off, and the parking brake is engaged. At all times disconnect the battery terminals to stop unintended electrical shocks. Utilizing applicable security gear, comparable to insulated gloves and eye safety, is paramount to stop accidents. Engaged on a trailer’s electrical system requires warning and a spotlight to element.

Trailer Wiring Connector Comparability

| Connector Sort | Pinout | Features |

|---|---|---|

| 7-way |

|

Offers energy and management for all lights and brakes on heavier trailers. |

| 4-way |

|

Offers energy and management for lights and cease lights, generally used for smaller trailers with out electrical brakes. |

This desk supplies a comparability of the commonest trailer wiring connector varieties, outlining their pinouts and the features every pin controls. Understanding these distinctions is important for selecting the proper connector for a specific trailer.

Understanding the Wiring Diagram

An important step in safely and successfully wiring your trailer’s brake system is knowing the wiring diagram. This doc will element the features of every wire, the elements of a trailer brake system, and methods to accurately interpret a diagram, guaranteeing correct connection and performance. This information is important for avoiding electrical hazards and guaranteeing your trailer brakes function as meant.A well-understood wiring diagram empowers you to make knowledgeable selections relating to the proper connections.

This permits for the prevention of expensive errors and potential security hazards. The right identification of every wire and element is significant for the dependable operation of the trailer brake system.

Features of Wires in a Trailer Wiring Harness

Understanding the precise operate of every wire within the trailer wiring harness is paramount for profitable set up and operation. Completely different wires carry numerous alerts and energy, every essential for correct brake system functioning.

- The energy wire supplies {the electrical} power essential to function the trailer brakes. Incorrectly figuring out and connecting this wire can result in brake malfunction or harm to the system.

- Floor wires full {the electrical} circuit. With out correct grounding, the trailer brake system won’t operate accurately.

- Brake sign wires carry the sign from the trailer brake controller to the trailer brakes. These alerts are important for activating the trailer’s braking mechanisms. Incorrect connection of those wires can result in poor braking efficiency or no braking in any respect.

Elements of a Trailer Brake System

The trailer brake system is comprised of a number of essential elements, all working in live performance to supply secure and efficient braking.

- Trailer Brake Controller: This system, typically mounted on the towing automobile, regulates the quantity of braking drive utilized to the trailer brakes. Correct adjustment of this system is essential for optimum braking efficiency.

- Trailer Brake Actuator: This element is sometimes called a brake meeting. It is a mechanical system that converts {the electrical} sign from the brake controller into hydraulic stress or mechanical drive, which is used to use the brakes.

- Brake Wiring Harness: This harness connects the trailer brake controller to the trailer’s brake actuators, carrying the required electrical alerts and energy.

Widespread Electrical Elements in Trailer Wiring

Quite a lot of electrical elements are utilized in trailer wiring. Appropriate identification and connection are essential for secure and dependable operation.

| Part | Description |

|---|---|

| Fuse | Protects electrical circuits from harm because of overcurrent. |

| Relay | Amplifies or switches electrical alerts, controlling the movement of energy to particular elements. |

| Change | Permits for the management of energy to particular elements of the trailer wiring system. |

| Wiring Connectors | Securely join totally different elements of the trailer wiring harness. |

Wire Colours and Features in a 7-Method Connector

A 7-way connector is an ordinary connector for trailer wiring. Understanding the colour codes is essential for proper set up.

- Crimson/White: Sometimes the facility wire.

- White/Black: Floor wire.

- White: Trailer working lights.

- Mild Blue: Left flip sign.

- Inexperienced: Proper flip sign.

- Yellow: Brake gentle.

- Brown: Reverse gentle.

Deciphering a Trailer Wiring Diagram

Efficiently deciphering a trailer wiring diagram entails a methodical method. Fastidiously study the diagram, noting the precise wire colours, their corresponding features, and the connections to varied elements.

A transparent understanding of the wiring diagram is important to keep away from electrical errors and guarantee correct trailer brake operation.

Thorough examination of the diagram, alongside a visible inspection of the connections, ensures correct and dependable operation. Pay shut consideration to the labeling, symbols, and element identification.

Wiring the Trailer Electrical System

Correctly wiring your trailer’s electrical system is essential for security and performance. A well-connected system ensures all lights function accurately and, critically, that trailer brakes work successfully when engaged. This part particulars the steps concerned in connecting the trailer’s electrical elements, connecting the trailer wiring to the tow automobile, putting in the trailer brake controller, and establishing correct grounding strategies.This course of requires cautious consideration to element and adherence to security pointers.

Incorrect wiring can result in malfunctions, harm, and even hazards on the street. Following these steps will guarantee a secure and dependable connection between your tow automobile and trailer.

Connecting Trailer Electrical Elements

Connecting the trailer’s electrical elements entails guaranteeing a sturdy and dependable energy supply for all lights and, importantly, the brake system. That is achieved by correctly connecting the wires to the suitable terminals on the trailer’s wiring harness. Make sure that every wire is securely fixed and that every one connections are correctly insulated to stop quick circuits and guarantee longevity.

A poorly related system might end in flickering lights, or worse, an entire failure of the trailer brake system, posing a major security danger.

- Confirm the proper polarity of all connections. Incorrect polarity could cause malfunctioning lights or harm elements.

- Use applicable wire connectors and crimp them tightly to make sure safe connections. Unfastened connections could cause intermittent issues or electrical shorts.

- Examine all connections for correct insulation and guarantee no uncovered wires are current. This helps stop electrical shocks or hearth hazards.

- Use wire connectors designed for the precise gauge of wire used to your trailer’s electrical system. Utilizing the unsuitable sort of connector can weaken the connection or harm the wire.

Connecting Trailer Wiring to Tow Car

Connecting the trailer wiring to the tow automobile is a essential step. It ensures the tow automobile’s electrical system supplies energy to the trailer’s lights and brake system. The method typically entails connecting the trailer’s wiring harness to a corresponding connector on the tow automobile. Fastidiously matching the proper wiring connections will stop electrical harm or malfunction.

- Find the suitable trailer wiring connector on the tow automobile. This connector is usually discovered below the automobile’s bumper or behind the automobile’s chassis.

- Fastidiously match the wires from the trailer harness to the corresponding wires on the tow automobile’s connector. Check with your automobile’s proprietor’s guide or the wiring diagram for the precise wire colours and connections.

- Securely connect the trailer wiring connector to the tow automobile connector utilizing the correct fasteners and guarantee a good, safe connection. It will make sure the trailer lights and brakes operate accurately and reliably.

- Double-check all connections to make sure no wires are pinched or broken. Any harm to the wiring could cause malfunction and potential security hazards.

Putting in the Trailer Brake Controller

Putting in the trailer brake controller is a essential step in guaranteeing secure and managed braking to your trailer. The brake controller regulates the braking drive utilized to the trailer, stopping extreme braking and wheel lock-up. Correct set up is significant to make sure secure operation.

- Select an acceptable location for the brake controller that’s simply accessible and supplies good visibility.

- Mount the brake controller in keeping with the producer’s directions, guaranteeing it’s securely hooked up and correctly aligned.

- Join the brake controller’s wiring to the tow automobile’s wiring harness, adhering to the producer’s specs. Incorrect connections might harm the brake controller or the tow automobile’s electrical system.

- Take a look at the brake controller’s performance by making use of the brakes on the tow automobile and guaranteeing the trailer brakes interact appropriately.

Significance of Correct Grounding Methods

Correct grounding is important for stopping electrical points and guaranteeing the protection of {the electrical} system. floor supplies a low-resistance path for present to movement again to the supply. Improper grounding can result in electrical shorts, harm, and even hearth hazards.

- Guarantee all elements have a safe floor connection. floor is essential for the secure and dependable operation of your trailer’s electrical system.

- Use applicable grounding wires and connectors. Use the proper measurement and sort of wire to make sure adequate conductivity and forestall harm.

- Join the bottom wire to a strong steel a part of the trailer body. A strong, unpainted steel a part of the body ensures a dependable and safe connection.

- Examine all floor connections recurrently to make sure they continue to be safe and free from corrosion. Corrosion or free connections can interrupt {the electrical} movement and trigger issues.

Connecting the Trailer Brake Controller to Tow Car Wiring

Connecting the trailer brake controller to the tow automobile’s wiring requires precision and a spotlight to element. This connection ensures the brake controller receives the required alerts to control the trailer brakes.

- Establish the correct wiring connections on the brake controller and the tow automobile. Seek the advice of the producer’s directions for each the brake controller and the tow automobile for correct wire identification.

- Fastidiously join the brake controller’s wires to the corresponding wires on the tow automobile’s wiring harness, guaranteeing correct polarity and safe connections. Incorrect connections can result in malfunctions.

- Take a look at the brake controller performance to substantiate that the trailer brakes activate appropriately when the tow automobile brakes are engaged. Thorough testing is essential to confirm the system’s operation.

- Double-check all connections to make sure they’re safe and correctly insulated. That is important to keep away from quick circuits and different electrical issues.

Troubleshooting Trailer Wiring and Brakes

Troubleshooting trailer wiring and brake points could be difficult, however a scientific method can considerably cut back frustration and get you again on the street safely. Understanding the widespread issues and their potential causes is vital to efficient prognosis and restore. This part supplies detailed steering on figuring out and resolving issues together with your trailer’s electrical system and brake elements.

Widespread Trailer Wiring Points

Figuring out the supply {of electrical} issues in trailer wiring is essential for environment friendly troubleshooting. A number of components can contribute to those points, starting from defective connections to broken wiring. Widespread issues embody free connections, corroded terminals, broken wiring, and issues with the trailer’s electrical system.

- Unfastened Connections: Unfastened connections are a frequent supply {of electrical} issues. Moisture, vibration, and stress on the wiring could cause connections to loosen over time. This could result in intermittent electrical issues, comparable to flickering lights or inoperable brakes. That is typically the primary place to examine if a trailer’s electrical system is performing up.

- Corroded Terminals: Corrosion on electrical terminals can impede the movement of electrical energy. That is very true in humid environments or when uncovered to street salt or different corrosive substances. Corroded terminals can lead to intermittent electrical issues, similar to free connections, in addition to full system failure.

- Broken Wiring: Bodily harm to the wiring, comparable to cuts, abrasions, or tears, can disrupt {the electrical} circuit. This harm can result in quick circuits, open circuits, or intermittent issues, which might result in points like no lights, or solely sure lights working.

- Issues with the Trailer’s Electrical System: Inside faults throughout the trailer’s electrical system, comparable to defective switches, fuses, or wiring, can even trigger issues. This might contain a broken wiring harness, defective trailer wiring, or issues with {the electrical} elements contained in the trailer itself. Cautious inspection of the trailer’s electrical system is important in these instances.

Diagnosing Trailer Brake System Issues

Efficient prognosis of trailer brake system issues begins with a methodical method. This entails checking numerous elements and assessing their performance. Correctly diagnosing these points is important to find out the foundation trigger and implement the proper repairs.

- Visible Inspection: A radical visible inspection of the brake system is step one within the diagnostic course of. Study the brake traces for any seen harm, kinks, or leaks. Test the brake elements for any apparent indicators of injury or put on.

- Practical Testing: Take a look at the performance of the trailer brakes. Make sure the brakes are engaged and disengaged correctly. Take note of any uncommon noises or resistance throughout the course of. Observe if the trailer brakes interact when the automobile’s brakes are engaged.

- Electrical System Checks: Confirm the correct operation of {the electrical} elements within the trailer brake system. Test the brake controller, wiring, and connections for any indicators of injury or malfunction. Confirm the facility provide to the trailer brake system and examine the operation of any relays or fuses within the circuit.

Strategies for Testing Trailer Brakes

A number of strategies can be utilized to check the performance of the trailer brakes. Every methodology supplies beneficial insights into the system’s efficiency.

- Handbook Take a look at: A guide check entails partaking the trailer brakes manually. That is helpful for verifying that the mechanical elements are functioning accurately.

- Diagnostic Instruments: Use diagnostic instruments like voltmeters and amp meters to measure voltage and amperage within the brake circuit. These measurements assist pinpoint the situation of any electrical issues. This methodology is essential for figuring out points with {the electrical} elements.

- Highway Take a look at: A street check is essentially the most sensible methodology for evaluating the general efficiency of the trailer brakes. Have interaction the trailer brakes below numerous circumstances, comparable to low pace and excessive pace, to evaluate their effectiveness. A street check simulates real-world circumstances and supplies a practical analysis of the trailer brake system’s efficiency.

Troubleshooting Desk for Trailer Brake System Issues

The desk under supplies a structured method to troubleshooting widespread trailer brake system issues.

| Drawback | Potential Causes | Troubleshooting Steps |

|---|---|---|

| Trailer brakes don’t interact | Defective brake controller, defective wiring, free connections, broken brake elements | Test brake controller operation, examine wiring for harm or free connections, check brake elements for correct operation |

| Trailer brakes interact intermittently | Unfastened connections, corroded terminals, defective switches | Tighten connections, clear terminals, check switches for correct operation |

| Trailer brakes interact however are ineffective | Low brake fluid, broken brake traces, worn brake pads | Test brake fluid stage, examine brake traces for harm, examine brake pad thickness |

Security Issues

Correctly wiring a trailer with brakes entails extra than simply connecting wires. It necessitates a radical understanding of security procedures and the potential hazards related to electrical methods. Ignoring these precautions can result in important dangers, from minor inconveniences to critical accidents. This part Artikels essential security concerns for working with trailer wiring and brakes.

Electrical Security Procedures

Secure electrical work begins with recognizing the inherent risks of excessive voltage and the significance of correct grounding and insulation. Improperly dealt with electrical methods can lead to electrical shocks, fires, or harm to gear.

- At all times disconnect the facility supply earlier than performing any wiring work. That is essential to stop unintended shocks and harm to gear.

- Use insulated instruments. Utilizing insulated instruments and gloves minimizes the chance {of electrical} shock. Make sure the insulation is undamaged and free of injury.

- Correct grounding is important. Grounding prevents electrical shocks and ensures secure operation of {the electrical} system. Make sure the trailer’s grounding system is undamaged and correctly related.

- Examine all wiring for harm. Search for frayed wires, uncovered conductors, or some other indicators of injury. Broken wiring have to be changed instantly to stop quick circuits and electrical hazards.

Excessive-Voltage Dangers

Working with excessive voltage presents important dangers. Even seemingly low voltages could be harmful if not dealt with accurately. The potential for electrical shock, burns, or gear harm necessitates cautious consideration to security protocols.

- Perceive the voltage ranking of the elements and the wiring system. That is essential for figuring out the suitable security measures and instruments to make use of.

- By no means work alone when dealing with high-voltage elements. A second particular person can present help and assist in the occasion of an emergency.

- Familiarize your self with {the electrical} codes and rules in your space. It will guarantee compliance with security requirements and assist keep away from potential authorized points.

- Use applicable private protecting gear (PPE), comparable to security glasses, gloves, and rubber boots, when working with electrical methods. That is essential for stopping contact with energized elements.

Pre-Journey Wiring Checks

Common inspections are essential to make sure the trailer wiring system is in optimum situation earlier than every journey. A pre-trip examine can stop surprising points and potential accidents.

- Visible inspection of the wiring. Search for indicators of injury, comparable to frayed wires, uncovered conductors, or free connections. This visible inspection ought to embody your entire wiring system, from the towing automobile to the trailer.

- Confirm all connections are safe. Test all electrical connections on each the towing automobile and the trailer for tightness. Any free connections ought to be tightened instantly.

- Take a look at the brake system. Carry out a radical check of the trailer brake system, guaranteeing all features are working accurately. A practical check will make sure the brakes are in working order, minimizing dangers throughout braking maneuvers.

- Test the lights. Confirm that every one trailer lights are functioning accurately, together with brake lights, flip alerts, and taillights. Correct functioning lights are important for security and visibility.

Connecting and Disconnecting the Trailer

Connecting and disconnecting the trailer requires cautious dealing with to stop harm to the wiring and electrical methods. Correct procedures reduce the chance of accidents and guarantee secure operation.

- Comply with the producer’s directions rigorously for connecting and disconnecting the trailer. These directions are important for secure operation and can element particular steps.

- Disconnect {the electrical} connection earlier than disconnecting the trailer hitch. This step helps stop unintended shocks and harm to {the electrical} system.

- Examine the trailer wiring after disconnecting the trailer. Search for any indicators of injury or put on. Doc any points for future restore.

- Retailer the trailer wiring correctly to stop harm and guarantee its longevity. This consists of protecting the wires away from sharp objects and stopping tangling.

Kinds of Trailer Brakes

Trailer brakes are essential for secure and managed braking, particularly when towing heavy masses. Understanding the various kinds of trailer brakes, their traits, and upkeep necessities is important for accountable towing. Choosing the proper brake system to your trailer relies on components like trailer weight, towing automobile capabilities, and native rules.Completely different trailer brake methods provide various ranges of efficiency and complexity.

Electrical and hydraulic brakes are the commonest varieties, every with its personal set of benefits and drawbacks. Electrical brakes are typically easier and cheaper to put in, whereas hydraulic brakes provide extra responsive braking energy, notably useful for heavier trailers. The choice ought to align with the trailer’s particular wants and the towing automobile’s capabilities.

Electrical Trailer Brakes

Electrical trailer brakes are a typical alternative for lighter trailers. These methods make the most of a set of electrically-activated brakes on the trailer. The braking motion is initiated by a sign from the towing automobile, which is transmitted via wiring.

- Performance: Electrical brakes function by activating a braking mechanism via electrical present. The towing automobile’s brake controller sends a sign to the trailer brakes, instructing them to interact. This technique usually depends on a mix of a controller, wiring, and brake elements on the trailer.

- Wiring Necessities: Particular wiring is important for the correct functioning of electrical trailer brakes. The wiring harness connects the towing automobile’s brake controller to the trailer brakes. Make sure the wiring is accurately related to keep away from malfunctions and security hazards.

- Upkeep: Common inspection of the wiring, connections, and brake elements is essential. Clear and lubricate brake elements as per producer suggestions to take care of optimum efficiency. Examine for any indicators of damage and tear, comparable to frayed wires or broken brake sneakers.

- Adjustment: Adjusting the brake elements, together with brake sneakers and wheel cylinders, is vital for optimum braking efficiency. Comply with the producer’s directions for correct adjustment procedures.

Hydraulic Trailer Brakes

Hydraulic trailer brakes present a extra highly effective and responsive braking system, particularly for heavier trailers. These methods make the most of a hydraulic stress system to activate the brakes.

- Performance: Hydraulic methods use hydraulic stress to use the brakes, leading to a extra sturdy braking drive. This technique leverages a mix of hydraulic traces, valves, and brake elements to create stress and interact the brakes. A proportional relationship exists between the braking drive utilized by the driving force and the hydraulic stress generated.

- Wiring Necessities: Wiring necessities for hydraulic brakes are just like electrical brakes, except for the necessity to connect with the hydraulic elements. Appropriate wiring and correct performance are essential for the protection and effectivity of the braking system.

- Upkeep: Repeatedly examine the hydraulic traces for leaks and harm. Test the brake fluid stage and make sure the fluid is in good situation. Comply with producer suggestions for brake fluid adjustments and different upkeep procedures.

- Adjustment: Hydraulic brake adjustment is often dealt with by the producer’s advisable procedures. Specialised instruments and data could also be mandatory for correct changes.

Comparability Desk

| Function | Electrical Brakes | Hydraulic Brakes |

|---|---|---|

| Energy | Decrease | Larger |

| Weight Capability | Appropriate for lighter trailers | Appropriate for heavier trailers |

| Price | Usually cheaper | Usually costlier |

| Complexity | Easier | Extra complicated |

Putting in and Connecting Trailer Brake Controller

Correct set up and connection of a trailer brake controller are essential for secure towing. A well-functioning controller ensures efficient braking of the trailer, stopping accidents and sustaining management throughout numerous driving circumstances. Appropriate set up and calibration are important to maximise braking efficiency and keep away from potential hazards.

Kinds of Trailer Brake Controllers

Trailer brake controllers are available in numerous varieties, every with particular options and functionalities. Understanding these variations helps in deciding on the suitable controller to your towing wants. Elements like towing capability, trailer sort, and private desire play a major position in choosing the proper controller.

- Electrical Proportioning Brake Controllers: These controllers use an electrical sign to modulate the trailer brakes primarily based on the automobile’s braking calls for. They supply a extra exact and responsive braking system, notably helpful for heavy masses or complicated towing eventualities. One of these controller usually provides adjustable sensitivity and response time settings for optimized efficiency.

- Hydraulic Proportioning Brake Controllers: These controllers use hydraulic stress to control the trailer brakes. They’re recognized for his or her robustness and skill to deal with demanding towing conditions. Hydraulic controllers often provide a extra simple set up and upkeep course of in comparison with electrical varieties.

- Pneumatic Proportioning Brake Controllers: These controllers use air stress to regulate the trailer brakes. Whereas much less widespread than electrical or hydraulic varieties, pneumatic controllers provide a constant and dependable braking system, notably useful in business or heavy-duty towing purposes.

Putting in a Trailer Brake Controller

Putting in a trailer brake controller entails a number of steps, beginning with deciding on an acceptable location and guaranteeing correct wiring connections. Cautious adherence to the producer’s directions is essential to keep away from potential electrical or mechanical points. Utilizing the proper mounting {hardware} and securing the controller are vital to take care of its structural integrity throughout towing.

- Mounting the Controller: Select a location in your automobile’s dashboard that’s simply accessible and will not hinder your view. Safe the controller utilizing the supplied mounting {hardware}, guaranteeing it is firmly hooked up and will not shift or vibrate throughout operation.

- Wiring the Controller: Fastidiously join the controller’s wiring to the tow automobile’s electrical system, following the wiring diagram supplied with the controller. This step entails connecting the facility supply, floor wire, and the brake management sign wire.

- Connecting the Controller to the Trailer: Join the trailer’s brake wiring to the controller’s corresponding ports, guaranteeing appropriate polarity and wire gauge. Correct connection ensures efficient communication between the tow automobile and the trailer’s braking system.

Connecting the Controller to the Tow Car

Connecting the trailer brake controller to the tow automobile requires exact wiring to make sure the braking system operates accurately. The wiring course of ought to observe the supplied diagrams and cling to vehicle-specific necessities. Connecting the brake management wire to the proper port is important to permit the controller to modulate the trailer’s brakes successfully.

- Establish the Brake Management Sign Wire: Find the suitable brake management sign wire in your automobile’s wiring harness. This wire transmits the braking sign from the brake pedal to the trailer brake controller.

- Join the Brake Management Wire: Join the brake management wire from the automobile to the corresponding enter port on the trailer brake controller. This connection permits the controller to obtain braking alerts from the tow automobile.

- Join Energy and Floor: Join the facility and floor wires from the controller to the suitable terminals in your automobile’s electrical system. Guarantee correct polarity and gauge to keep away from harm to the controller or the automobile’s electrical system.

Calibrating the Trailer Brake Controller

Calibrating the trailer brake controller is important to optimize its efficiency and make sure the trailer brakes reply appropriately to the tow automobile’s braking instructions. The calibration course of entails adjusting the controller’s settings to match the trailer’s braking traits.

- Comply with Producer Directions: Check with the producer’s directions for particular calibration procedures, which range primarily based on the kind of controller. These directions often element the steps required to regulate the controller’s sensitivity and response time.

- Modify Sensitivity and Response Time: Utilizing the calibration instruments supplied, alter the sensitivity and response time settings to match the trailer’s braking traits. Experiment with totally different settings to seek out the optimum stability between responsiveness and effectiveness.

- Take a look at the Calibration: After finishing the calibration course of, check the trailer brake system in numerous braking eventualities to substantiate the effectiveness of the changes. Observe how the trailer brakes reply to totally different braking intensities.

Brake Controller Varieties and Options

| Controller Sort | Options |

|---|---|

| Electrical Proportioning | Exact braking management, adjustable sensitivity, responsive to varied braking circumstances. |

| Hydraulic Proportioning | Strong and dependable braking, appropriate for heavy masses, typically simple set up and upkeep. |

| Pneumatic Proportioning | Constant and reliable braking, usually utilized in heavy-duty purposes. |

Sustaining Trailer Wiring and Brakes

Correct upkeep of your trailer’s wiring and braking system is essential for secure and dependable operation. Neglecting these methods can result in expensive repairs, compromised security, and potential accidents. This part particulars preventative upkeep steps, inspections, and procedures for protecting your trailer’s braking system in optimum situation.Common upkeep considerably extends the lifespan of your trailer’s wiring and braking elements.

By proactively addressing potential points, you possibly can stop expensive repairs and be certain that your trailer operates safely and effectively.

Preventative Upkeep Steps for Trailer Wiring

Sustaining the integrity of the trailer’s wiring is significant for stopping electrical malfunctions and guaranteeing the correct operation of the brake system. These preventative measures assist stop issues earlier than they happen.

- Repeatedly examine all wiring connections for indicators of corrosion, harm, or looseness. Pay specific consideration to connections on the trailer’s electrical panel, the hitch, and some other junctions.

- Examine the wiring harness for any indicators of chafing, abrasion, or harm from street particles. Defend the wiring from extreme stress by securing it appropriately.

- Make sure that all wiring is correctly insulated and free from uncovered wires. Broken insulation can result in quick circuits and hearth hazards. If any insulation is broken, change it instantly.

- Clear any amassed filth or particles from the wiring harness and connections to enhance electrical conductivity and forestall corrosion.

Significance of Common Inspections for the Trailer Brake System

Common inspections of the trailer brake system are essential to detect potential points early on, permitting for immediate repairs and stopping extra critical issues.

- Visually examine the brake sneakers, brake drums, and brake cables for put on and tear, harm, or any indicators of corrosion.

- Test the brake fluid ranges within the brake traces for correct hydraulic operate. Make sure that the fluid is throughout the advisable vary.

- Examine the brake hoses for cracks, bulges, or leaks. Change any broken brake hoses instantly.

- Study the brake pads or linings for thickness. Skinny pads or linings point out put on and necessitate alternative.

Lubricating Trailer Brake Elements, Tips on how to wire a trailer with trailer brakes

Lubricating trailer brake elements is a necessary facet of preventative upkeep, guaranteeing clean operation and increasing the lifespan of the system.

- Correct lubrication of the trailer brake elements is important to make sure clean operation. This helps to stop friction and put on and tear.

- Check with the producer’s directions for the precise lubricants and software procedures to your trailer’s brake elements. Use the advisable lubricants for optimum efficiency.

- Lubricate brake elements comparable to wheel bearings, brake drums, and brake sneakers as per the producer’s specs. Comply with the lubrication schedule Artikeld within the proprietor’s guide.

Inspecting Wiring Connections

Common inspection of wiring connections is essential to make sure correct electrical continuity and forestall electrical malfunctions.

- Visually examine all wiring connections for tightness and securement. Make sure that all connections are correctly soldered or crimped to stop loosening and potential quick circuits.

- Test the connections for corrosion, oxidation, or any indicators of injury. If corrosion is discovered, clear and re-secure the connections.

- Confirm that every one connections are correctly insulated to stop quick circuits. Change any broken insulation instantly.

Cleansing and Sustaining the Trailer Brake System

Correct cleansing and upkeep of the trailer brake system guarantee optimum efficiency and delay the lifespan of the system.

- Repeatedly clear the trailer brake elements, such because the brake drums and brake sneakers, to take away amassed filth, mud, and particles. Use applicable cleansing brokers to take away grime and corrosion.

- Examine the brake traces for any indicators of leaks or harm. Change any broken brake traces instantly.

- Examine and clear the brake controller elements, together with {the electrical} connections and sensors, to take care of optimum efficiency.

Concluding Remarks

In conclusion, wiring a trailer with trailer brakes requires cautious consideration to element and adherence to security protocols. This information has supplied a complete overview, masking every little thing from understanding totally different wiring methods and brake varieties to troubleshooting widespread issues. Bear in mind to all the time prioritize security and search skilled assist if wanted. Now you are geared up with the data to confidently hook up your trailer and revel in secure and worry-free journeys!

Important Questionnaire: How To Wire A Trailer With Trailer Brakes

What are the widespread causes {of electrical} issues in trailer wiring?

Unfastened connections, broken wires, corroded terminals, and defective elements just like the trailer brake controller are widespread culprits. Checking connections and inspecting the wiring for harm is important for stopping electrical points.

How do I check the performance of the trailer brakes?

After connecting every little thing, interact the trailer brakes utilizing the brake controller in your automobile. If the trailer brakes do not activate, there’s an issue that must be identified.

What are the various kinds of trailer brake controllers?

Widespread varieties embody proportional and non-proportional controllers. Proportional controllers alter braking drive primarily based on the automobile’s braking enter, offering more practical braking management. Non-proportional controllers present a hard and fast braking drive.

What are the precise wiring necessities for electrical trailer brakes?

Electrical trailer brakes usually require particular wire colours and connections for correct performance. Seek the advice of your trailer’s wiring diagram and the producer’s directions for exact connections.