PLC tips on how to add 4-20 correction issue units the stage for exact industrial knowledge acquisition. This information delves into the essential steps for implementing 4-20mA correction components in Programmable Logic Controllers (PLCs), guaranteeing correct readings in numerous purposes. Understanding the nuances of 4-20mA present loops and their inherent susceptibility to environmental components is paramount for attaining dependable outcomes.

The method encompasses an in depth clarification of 4-20mA sensor varieties, widespread error sources, and the mathematical procedures for calculating correction components. Actual-world examples, case research, and troubleshooting methods are offered to empower readers with sensible utility expertise.

Introduction to 4-20mA and PLC Methods

The 4-20mA present loop is a broadly used commonplace in industrial automation for transmitting analog indicators. It gives a number of benefits, together with immunity to noise, easy wiring, and lengthy transmission distances, making it a sturdy selection for a lot of purposes. This commonplace facilitates communication between sensors and programmable logic controllers (PLCs), enabling exact monitoring and management of varied course of parameters.This part gives a complete overview of the 4-20mA present loop, its integration with PLCs, and the crucial function of linearization and correction components in guaranteeing correct knowledge acquisition and management.

Understanding these facets is important for efficient implementation and troubleshooting in industrial automation programs.

4-20mA Present Loop Commonplace

The 4-20mA present loop is a standardized methodology for transmitting analog indicators. A 4mA present corresponds to the bottom measurable worth, whereas 20mA represents the best. The sign’s present varies linearly with the measured worth. This linear relationship is essential for correct knowledge illustration.

Typical Enter Vary of a 4-20mA Sensor

Sensors used with the 4-20mA present loop usually have an outlined enter vary. This vary is the bodily measurement that the sensor converts into the 4-20mA sign. As an illustration, a temperature sensor might need a spread of 0 to 100°C, whereas a strain sensor might need a spread of 0 to 100 PSI. The 4-20mA sign straight displays the measured worth inside this enter vary.

PLC Interface with 4-20mA Indicators

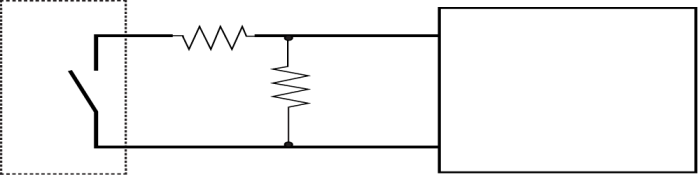

PLCs usually interface with 4-20mA indicators by way of devoted modules or enter playing cards. These modules have circuitry to transform the analog present sign right into a digital illustration that the PLC can course of. The conversion course of includes sampling the present and changing it right into a voltage that’s proportional to the present. The digital worth is then utilized by the PLC’s programming logic.

Linearization in 4-20mA Methods

Linearization is the method of guaranteeing that the connection between the sensor’s enter and the 4-20mA output is actually linear. That is crucial for correct knowledge interpretation. Some sensors may exhibit non-linear conduct, requiring calibration or correction to take care of the linear relationship between enter and output. The accuracy of the measurement is dependent upon the effectiveness of the linearization course of.

Want for Correction Elements in Actual-World Functions

Actual-world sensor readings are sometimes influenced by varied components resembling ambient temperature, strain, and humidity. These components can introduce deviations from the best linear relationship. Correction components are used to compensate for these deviations and guarantee correct illustration of the measured variable.

Sensor Enter/Output Vary Desk

| Sensor Kind | Enter Vary (mA) | Output Vary (e.g., 0-100%) |

|---|---|---|

| Temperature Sensor | 4-20mA | 0-100°C |

| Strain Sensor | 4-20mA | 0-100 PSI |

| Circulate Sensor | 4-20mA | 0-1000 L/min |

Understanding Correction Elements

-20mA indicators are essential for industrial automation, transmitting knowledge from sensors to Programmable Logic Controllers (PLCs). Nonetheless, varied components can introduce errors into these indicators, impacting the accuracy of the measurements. Understanding these components and their related correction strategies is significant for guaranteeing dependable and exact knowledge acquisition.Environmental situations, sensor traits, and transmission points can all contribute to inaccuracies in 4-20mA indicators.

Correcting for these errors is important for correct course of management and decision-making in industrial settings. The accuracy of a measurement relies upon not solely on the sensor itself, but additionally on the encompassing situations and the methodology used to account for the errors.

Sources of Error Affecting 4-20mA Indicators

Varied components can have an effect on the accuracy of 4-20mA indicators. These embrace sensor ageing, variations in environmental situations, and sign transmission issues.

- Sensor Drift and Growing older: Sensors, like several element, degrade over time. This results in gradual adjustments of their output, impacting the accuracy of the 4-20mA sign. This drift could be a results of inside element degradation, or the affect of environmental components like temperature and humidity.

- Environmental Elements: Temperature, strain, and humidity are vital sources of error. As an illustration, a temperature sensor may produce an inaccurate studying if the ambient temperature deviates considerably from its calibrated vary. Equally, strain fluctuations can have an effect on strain sensors, whereas humidity can impression moisture-sensitive sensors. These deviations have to be fastidiously thought-about and corrected.

- Sign Transmission Points: Sign attenuation, noise, and cable resistance throughout transmission can introduce errors into the 4-20mA sign. Longer cable lengths, poor cable high quality, and interference from different electrical indicators could cause these issues. These components have to be accounted for throughout the design and implementation phases of the system.

Kinds of Correction Elements

Varied correction components are utilized to compensate for the errors launched by totally different environmental influences.

- Temperature Correction: Temperature is a prevalent issue influencing sensor readings. A temperature sensor may produce a better output for a given temperature if the ambient temperature is increased than the calibration temperature. Correction components typically account for these variations through the use of a calibration curve or a mathematical mannequin relating sensor output to temperature.

- Strain Correction: Strain adjustments can considerably have an effect on the readings of strain sensors. As an illustration, a strain sensor may output a better worth for a given strain if the ambient strain is increased than the calibration strain. Correction components are used to account for these variations.

- Humidity Correction: Humidity can have an effect on moisture-sensitive sensors. A humidity sensor may present inaccurate readings in environments with excessive or low humidity ranges. Calibration curves or mathematical fashions are sometimes used to right for these errors.

Examples of Environmental Affect on Sensor Readings

Environmental situations have a big impression on sensor accuracy.

- Temperature Influence on Resistance Thermometers: A resistance thermometer used to measure temperature may exhibit a better resistance studying if the ambient temperature is increased than the calibration temperature. This deviation from the calibrated worth must be accounted for to make sure correct temperature measurement.

- Strain Influence on Strain Sensors: A strain sensor may give a better output for a given strain if the ambient strain is increased than the calibration strain. The ensuing measurement error requires acceptable correction.

Significance of Calibration, Plc tips on how to add 4-20 correction issue

Calibration is crucial for guaranteeing the accuracy of 4-20mA indicators. Calibration procedures present a baseline for comparability, enabling the identification and correction of errors.

- Establishing a Baseline: Calibration establishes a reference level for the sensor’s output beneath particular environmental situations. This permits for comparability with subsequent measurements, enabling the detection of any deviations and the appliance of acceptable correction components.

- Figuring out Errors: Calibration helps in figuring out systematic errors within the sensor’s readings. That is essential for guaranteeing that measurements are correct and dependable.

Comparability of Correction Issue Methodologies

Completely different methodologies are employed for correcting 4-20mA indicators.

| Methodology | Description | Benefits | Disadvantages |

|---|---|---|---|

| Linear Interpolation | Makes use of a linear equation to estimate the correction issue. | Easy to implement. | Much less correct for vital deviations from the calibration vary. |

| Polynomial Interpolation | Makes use of a polynomial equation to estimate the correction issue. | Extra correct than linear interpolation. | Extra advanced to implement. |

| Lookup Tables | Pre-calculated correction components saved in a desk. | Quick and simple. | Restricted accuracy primarily based on the desk decision. |

Implementing Correction Elements in PLC Programming

Making use of correction components to sensor readings in Programmable Logic Controllers (PLCs) is essential for correct course of management. Inaccurate readings, stemming from varied sensor traits or environmental influences, can result in suboptimal efficiency and even system failures. Implementing these corrections inside the PLC program ensures the system responds to the precise course of situations slightly than flawed sensor knowledge.Correct management programs depend on exact knowledge.

By incorporating correction components into the PLC program, the controller accounts for sensor inaccuracies, resulting in extra dependable and environment friendly operations. This enhanced accuracy interprets to improved product high quality, diminished waste, and enhanced security inside industrial processes.

Typical Steps in Making use of a Correction Issue

Implementing a correction think about a PLC program includes a number of key steps. First, establish the supply of the error within the sensor readings. Subsequent, decide the suitable correction formulation primarily based on the character of the error. This formulation usually includes mathematical operations, typically incorporating variables representing the sensor output, environmental components, or different related knowledge. Lastly, incorporate the correction formulation into the PLC program, guaranteeing its integration with present management logic.

Calculating Correction Elements Primarily based on Sensor Knowledge

Correction components are sometimes calculated utilizing a mixture of sensor readings and identified parameters. This calculation can contain varied mathematical operations. For instance, a linear relationship between sensor output and the precise course of variable could be represented as:

Corrected Worth = Sensor Output

Achieve + Offset

the place Achieve and Offset are calculated from calibration knowledge. The method typically includes gathering knowledge from the sensor beneath varied identified situations, producing a calibration curve, and deriving the Achieve and Offset values.

Offset and Achieve Adjustment

Offset and acquire changes are basic elements of implementing correction components. Offset represents a continuing worth that must be added or subtracted from the sensor studying. Achieve represents a multiplicative issue that scales the sensor studying. Adjusting these parameters fine-tunes the sensor output to precisely replicate the method variable.

Circulate Chart Illustrating the Technique of Making use of a Correction Issue

[Insert a flow chart here. The flow chart should begin with a PLC receiving sensor data. It should then branch to calculate the correction factor based on the sensor reading and known parameters. Then, it should apply the correction factor, adjusting the offset and gain as needed. Finally, the corrected value should be used in the control logic.]The circulation chart visually represents the sequence of operations from sensor enter to output correction, clearly displaying the levels of calculation and utility.

PLC Programming Languages and Correction Issue Implementation Examples

| Programming Language | Instance Implementation (Conceptual) |

|---|---|

| Ladder Logic |

A rung within the ladder logic program would learn the sensor enter, calculate the correction issue (utilizing a operate block or separate calculations), after which output the corrected worth to a register. |

| Structured Textual content (ST) |

In ST, a operate or operate block would encapsulate the correction issue calculation, taking the sensor enter as enter and returning the corrected worth. This operate might be known as inside the primary management logic.

|

The desk demonstrates that varied PLC programming languages provide totally different approaches to implementing correction issue calculations. The selection of language is dependent upon the particular PLC system and the programmer’s familiarity with every language.

Sensible Examples and Case Research

Making use of correction components to 4-20mA sensor knowledge is essential for correct measurements in varied industrial settings. These components account for variations in sensor efficiency, environmental situations, and measurement methods. Understanding and implementing these components ensures dependable knowledge interpretation and environment friendly course of management.Implementing correction components in a PLC system considerably enhances the reliability and accuracy of the acquired knowledge.

This course of includes figuring out the related correction components for the particular sensor and surroundings, incorporating these components into the PLC program, and validating the outcomes in opposition to identified values.

Temperature Sensor Instance

A temperature sensor, generally utilized in industrial processes, typically reveals a non-linear response to temperature adjustments. A 4-20mA output sign from a temperature sensor must be corrected for this non-linearity. Take into account a sensor with a identified offset and acquire error. If the sensor output at 25°C is 10mA, and the output at 50°C is 18mA, the sensor’s response isn’t straight proportional.

A correction issue is required to map the 4-20mA sign to the precise temperature. The PLC program wants to include this correction issue into the calculations, guaranteeing the displayed temperature is correct, whatever the sensor’s output.

Completely different Sensor Varieties and Correction Elements

Completely different sensor varieties have totally different correction components. The desk under Artikels widespread eventualities:

| Sensor Kind | Typical Error Supply | Correction Issue Software |

|---|---|---|

| Thermocouple | Temperature of the junction, wire resistance, and materials properties | Calibration curves and tables, or mathematical fashions, are sometimes used to right for the assorted sources of error |

| RTD (Resistance Temperature Detector) | Ambient temperature, wire resistance, and lead resistance | Mathematical formulation or lookup tables are usually used to compensate for these errors. |

| Pressure Gauge | Temperature variations, environmental situations, and mechanical stress | Calibration curves or mathematical fashions are important to regulate for the pressure and the environmental situations. |

| Circulate Meter | Fluid viscosity, pipe diameter, and strain variations | Correction components are primarily based on empirical knowledge or theoretical fashions to account for fluid properties and system parameters. |

Case Examine: Improved Knowledge Accuracy in a Chemical Reactor

In a chemical reactor utility, temperature readings from thermocouples have been inaccurate with out correction components. The method used thermocouples to observe response temperatures. With out correction components, the temperature readings various considerably from the anticipated values, resulting in inefficiencies within the course of. Implementing correction components, derived from the thermocouple calibration curve and environmental knowledge (ambient temperature), considerably diminished the error within the temperature readings.

This led to improved management of the response parameters and optimized yield, leading to a considerable price financial savings.

Calculating the Correction Issue

The correction issue calculation is dependent upon the particular sensor and utility. For a temperature sensor, the correction issue is commonly a operate of the temperature distinction between the sensor and the reference temperature. As an illustration, a formulation might be used to account for the change in resistance of the sensor with temperature. A mathematical mannequin, primarily based on the sensor’s traits and the surroundings, may help to find out the suitable correction issue.

Correction issue = (Measured Worth – Anticipated Worth) / Anticipated Worth

Benefits of Making use of Correction Elements

Making use of correction components improves the accuracy of information acquisition, which results in:

- Enhanced course of management: Correct knowledge permits higher management of processes, lowering variability and enhancing effectivity.

- Improved product high quality: Exact measurements result in higher management over manufacturing processes, leading to increased high quality merchandise.

- Diminished upkeep prices: Early detection of points by way of correct measurements permits for well timed upkeep and avoids expensive gear failures.

- Elevated profitability: Improved course of effectivity and product high quality contribute to increased profitability.

Widespread Errors in Implementing Correction Elements

Widespread errors embrace:

- Incorrect collection of correction components: Selecting the incorrect correction issue for the sensor and surroundings can result in inaccurate outcomes.

- Ignoring environmental components: Elements like ambient temperature, strain, and humidity can considerably have an effect on sensor readings, and neglecting these components may end up in inaccurate correction.

- Inadequate calibration: Insufficient calibration of the sensor can result in errors within the correction components, which in flip have an effect on the accuracy of the info.

- Lack of validation: With out validating the corrected knowledge in opposition to identified values, it is tough to establish the accuracy of the correction.

Superior Issues

Making use of correction components to 4-20mA sensor readings in PLC programs requires cautious consideration of varied components past primary calculations. Understanding the potential impression of sensor ageing, totally different calculation strategies, and the nuances of utility choice is essential for correct and dependable knowledge acquisition. This part delves into these superior facets, highlighting the significance of information validation and the dangers related to incorrect issue utility.Correct 4-20mA sign interpretation depends on the upkeep of steady sensor efficiency.

The inherent limitations of real-world programs demand a deeper understanding of the dynamic nature of those corrections. Addressing these points with acceptable methods is important for industrial processes.

Influence of Sensor Growing older on Correction Elements

Sensor efficiency degrades over time as a consequence of components like materials fatigue, environmental publicity, and inside element put on. This degradation can considerably alter the sensor’s output, affecting the accuracy of the correction components. Common recalibration and monitoring of sensor efficiency are very important to sustaining knowledge integrity. In some instances, a correction issue may have to be adjusted periodically primarily based on sensor age and utilization historical past.

This ensures that the correction issue stays efficient over the sensor’s operational lifetime. Failure to account for sensor ageing can result in inaccurate course of management, leading to decreased effectivity and potential security hazards.

Comparability of Completely different Correction Issue Calculation Strategies

Varied strategies exist for calculating correction components, every with its personal strengths and weaknesses. Linear interpolation, polynomial becoming, and statistical regression are widespread methods. The selection of methodology is dependent upon the character of the sensor output relationship with the measured variable. As an illustration, linear interpolation is appropriate for sensors exhibiting a near-linear relationship, whereas polynomial becoming could be crucial for extra advanced curves.

Statistical regression can be utilized to mannequin the connection between the sensor output and the measured variable with consideration of measurement errors. Cautious analysis of the info and the traits of the sensor are crucial for selecting essentially the most acceptable methodology.

Selecting the Applicable Correction Issue Primarily based on the Particular Software

The collection of the suitable correction issue is crucial for correct knowledge interpretation. Elements like the particular sensor kind, working surroundings, and anticipated vary of measurement values all play a job. Consideration have to be given to the diploma of precision required for the appliance. As an illustration, a course of requiring excessive precision, resembling in pharmaceutical manufacturing, would necessitate a extra subtle correction issue calculation than a general-purpose course of management utility.

Complete testing and validation are important for guaranteeing the correction issue precisely displays the particular utility’s wants.

Significance of Knowledge Validation After Making use of Correction Elements

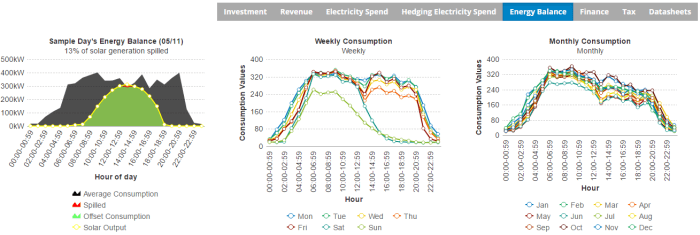

Knowledge validation is essential after making use of correction components. This includes checking for inconsistencies, outliers, and sudden developments within the corrected knowledge. Discrepancies may point out points with the correction issue itself, the sensor, or the info acquisition system. Thorough evaluation of the validated knowledge may help establish potential issues early and forestall expensive errors or security hazards. Visualizations of the info, together with graphs and histograms, might be helpful for figuring out patterns and developments.

Potential Dangers of Making use of Incorrect Correction Elements

Making use of incorrect correction components can result in vital points. Inaccurate readings may end up in improper management of the method, probably resulting in diminished effectivity, product defects, or security issues. In excessive instances, the inaccurate issue could trigger harmful operational situations. The chance of making use of an incorrect correction issue is straight proportional to the severity of the method being managed.

Desk of Completely different Sensor Varieties and Typical Correction Elements

| Sensor Kind | Typical Correction Elements | Notes |

|---|---|---|

| Temperature Sensors (Thermocouples) | Elements associated to temperature-dependent materials properties, wire resistance, and junction potential. | Calibration often wanted as a consequence of temperature dependence. |

| Strain Sensors (Pressure Gauge) | Elements associated to temperature, humidity, and materials properties of the sensing component. | Elements change primarily based on the particular kind of pressure gauge. |

| Circulate Sensors (Turbine) | Elements associated to viscosity, density, and temperature of the fluid being measured. | Correction components are sometimes extremely particular to the fluid kind. |

| Stage Sensors (Ultrasonic) | Elements associated to temperature, ambient strain, and sensor-to-target distance. | Elements might be considerably affected by air density variations. |

Troubleshooting and Upkeep: Plc How To Add 4-20 Correction Issue

Sustaining correct 4-20mA readings and guaranteeing the reliability of PLC programs incorporating correction components requires a proactive method to troubleshooting and upkeep. Common checks and immediate identification of points forestall expensive downtime and guarantee constant knowledge integrity. This part particulars methods for figuring out and resolving widespread issues associated to sensor calibration and correction issue implementation inside PLC programs.

Widespread Troubleshooting Points

Addressing potential issues in 4-20mA programs with correction components requires a scientific method. Errors can stem from varied sources, together with sensor malfunction, wiring points, or improper PLC programming. A methodical troubleshooting course of is essential for pinpointing the foundation trigger and restoring correct readings.

Figuring out Sensor Calibration Points

Correct sensor calibration is prime for dependable 4-20mA readings. Deviation from anticipated calibration can introduce errors into the correction issue calculations, resulting in inaccurate knowledge. Strategies for verifying sensor calibration embrace utilizing a calibrated multimeter to test the output sign at identified enter values. Discrepancies between the anticipated and measured output point out calibration points that want speedy consideration.

Troubleshooting PLC Programming Errors

Incorrect PLC programming can considerably impression the accuracy of correction components. Reviewing the PLC program for errors within the calculation of the correction issue is a crucial step. Debugging the PLC code to establish and resolve any errors is important for correct outcomes. Think about using a PLC simulator to check this system and establish potential points earlier than implementing it in a reside system.

Common Upkeep of 4-20mA Methods

Common upkeep of 4-20mA programs and their related correction components is important for sustaining accuracy and stopping potential points. Common checks of sensor connections, cabling, and sign integrity assist keep away from unexpected issues. Documentation of calibration dates and any upkeep carried out is crucial for monitoring the efficiency of the system over time. Periodically recalibrating sensors and updating correction components primarily based on the most recent calibration knowledge can also be important.

Upkeep Finest Practices for Correct Sensor Readings

Sustaining correct sensor readings includes a number of greatest practices. Implementing correct grounding methods minimizes noise and interference, guaranteeing constant sensor output. Common inspection of wiring for harm or corrosion helps preserve sign integrity. Retaining detailed data of upkeep actions, calibration knowledge, and any troubleshooting steps taken is essential for future reference and downside decision. This complete method helps make sure the long-term reliability and accuracy of the system.

Desk of Potential Issues and Options

| Potential Drawback | Attainable Resolution |

|---|---|

| Sensor output sign outdoors the 4-20mA vary | Confirm sensor connections, test for wiring points, and recalibrate the sensor. |

| Inconsistent sensor readings | Examine sensor mounting, test for environmental components affecting the sensor, and re-calibrate. |

| PLC program errors in correction issue calculation | Evaluation PLC code, debug this system, and validate the correction issue algorithm. |

| Incorrect wiring connections | Confirm all wiring connections, establish any broken wires, and guarantee correct grounding. |

| Noise interference on the 4-20mA sign | Implement shielding measures for the sign cables, enhance grounding, and establish sources of electromagnetic interference. |

Final Recap

In conclusion, precisely incorporating 4-20mA correction components in PLC programming is important for attaining dependable and exact knowledge in industrial settings. This complete information gives a sturdy framework for understanding and implementing these components, overlaying all the things from basic ideas to superior concerns. By understanding the components influencing sensor readings and the steps for implementing correction, operators can improve the reliability and accuracy of their industrial processes.

FAQ Insights

What are the most typical sources of error in 4-20mA indicators?

Widespread sources of error embrace temperature fluctuations, strain variations, humidity adjustments, sensor ageing, and variations within the sensor’s inherent traits. Calibration errors and incorrect set up may contribute to inaccuracies.

How do I select the appropriate correction issue for my particular utility?

The choice course of includes figuring out the particular environmental components impacting the sensor, consulting sensor datasheets for typical correction components, and probably conducting discipline checks to find out essentially the most appropriate correction methodology.

What are the potential dangers of making use of incorrect correction components?

Making use of incorrect correction components can result in inaccurate readings, defective course of management, gear malfunctions, and in the end, monetary losses as a consequence of operational inefficiencies and potential security hazards.

How do I troubleshoot points with sensor calibration and correction?

Troubleshooting includes checking sensor connections, verifying sensor calibration, reviewing PLC programming for errors, and evaluating environmental situations affecting the sensor. Comparability with historic knowledge and sensor producer tips is commonly useful.